Achieving Optimal Oil Decolorization with BE195A Bleaching Earth

| Key Takeaway | Description |

|---|---|

| High-Efficiency Decolorization | BE195A Bleaching Earth effectively removes pigments and impurities, ensuring high-quality oil for edible and industrial use. |

| Supports Eco-Friendly Practices | Clay-based processing reduces chemical usage, enabling sustainable and responsible oil refining. |

| Versatile Applications | Suitable for both food-grade and industrial oils, providing enhanced clarity and stability across various types of oils. |

| Meets Refining Standards | BE195A helps maintain compliance with industry standards for oil quality and color, meeting consumer expectations. |

| Cost-Effective and Reliable | Improves efficiency in oil processing, reduces waste, and delivers consistent, reliable results for long-term use. |

Table Of Contents

“BE195A Bleaching Earth ensures oils are not just clear but also of the highest quality, meeting both industry standards and consumer expectations.”

Introduction

In oil refining, color isn’t just about aesthetics; it’s about quality—and that’s where BE195A Bleaching Earth makes a difference. Oil decolorization is a critical step in producing oils that meet the high standards of both consumers and regulatory bodies. BE195A Bleaching Earth offers a powerful solution to refine edible and industrial oils, targeting pigments and contaminants that impact oil clarity and quality. Through this article, we’ll explore how BE195A transforms the decolorization process, enhancing the overall value of oils while supporting sustainability and efficiency in oil purification.

When I first started working with BE195A, I was struck by its precision and efficiency in oil decolorization. Not only does it improve the visual appeal of oils, but it also contributes to the overall quality and stability of the final product. Join me as we dive into the details of BE195A’s decolorization capabilities and discover how it supports cleaner, purer, and more sustainable oil refining.

The Importance of Oil Decolorization in Refining

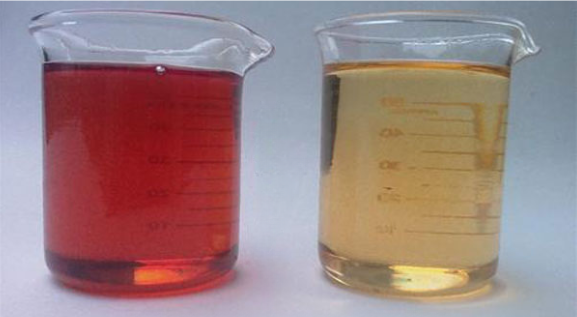

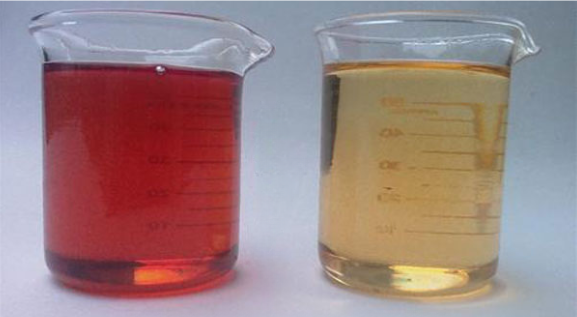

Decolorization is a key step in refining oils, ensuring that they meet both quality standards and consumer expectations. The presence of pigments and impurities can affect not just the appearance but also the perceived quality of edible oils. Oil decolorization removes these unwanted elements, transforming oils from raw and murky to clear and appealing. This step is especially crucial in edible oil refining, where consumers often judge quality by appearance.

In the world of industrial oil purification, clarity is equally important. Pigments can signal the presence of contaminants, which may impact the oil’s performance in various applications. Removing pigments from oils is about more than just looks—it’s about improving oil quality and ensuring that the product meets industry standards for purity. By refining vegetable oils to the desired clarity, we can elevate their quality and broaden their application in both food-grade and industrial settings.

Oil Decolorization

| Aspect | Description |

|---|---|

| Primary Function | Removes unwanted pigments and impurities from oils |

| Key Benefits | Enhances oil clarity, improves quality, and meets consumer expectations |

| Applications | Suitable for edible oils (e.g., vegetable oils) and industrial oils |

| Environmental Impact | Supports eco-friendly refining practices, reducing chemical waste |

| Cost-Effectiveness | Reduces need for repeated filtration, lowers operational costs, and extends the lifecycle of oils |

| Compatible Methods | Works well with other oil purification techniques, including clay-based and chemical treatments |

How BE195A Bleaching Earth Removes Pigments from Oils

BE195A Bleaching Earth tackles oil decolorization with precision, targeting pigments and impurities at the molecular level. Using an adsorption process, BE195A attracts and binds with contaminants, effectively removing them from the oil. This process is highly effective for removing pigments from oils, ensuring that the final product is clear and free from unwanted colors. The activated clay in BE195A has a high surface area, which allows it to capture impurities efficiently, making it a standout in the realm of bleaching earth applications.

In my experience, BE195A has consistently delivered impressive results. I remember a batch of vegetable oil that seemed hopelessly discolored. With BE195A, we were able to restore its clarity and quality, proving that this activated clay is not only effective but also reliable. By using BE195A, I can achieve the level of oil clarity necessary for high-quality applications, whether it’s for food-grade products or industrial oils.

Key Impurities Removed by BE195A in Oil Decolorization

| Impurity | Impact on Oil Quality | Removal Benefit |

|---|---|---|

| Pigments | Affects oil color and aesthetic appeal | Enhances clarity and visual appeal |

| Metals | Leads to oxidation and degradation | Improves stability and shelf life |

| Free Fatty Acids | Causes rancidity and unpleasant taste | Enhances flavor and quality |

| Oxidation Byproducts | Contributes to oil spoilage | Maintains oil freshness |

| Sulfur Compounds | Affects odor and compliance | Ensures regulatory compliance |

BE195A Bleaching Earth addresses some of the most stubborn impurities in industrial oil treatment, particularly heavy metals and organic residues that can degrade oil quality. Its activated clay structure provides a high adsorption capacity, which is crucial for capturing these impurities that other methods often miss. I’ve worked with oils that seemed beyond recovery due to their contaminant load, but BE195A consistently manages to pull through, restoring clarity and stability. Compared to synthetic adsorbents, BE195A offers a natural and effective solution, making it indispensable for thorough oil purification.

Benefits of Using BE195A for Oil Decolorization

Beyond color, BE195A offers a range of benefits that make it a staple in oil purification. First, it significantly enhances oil clarity, improving the visual appeal and overall quality of the oil. This is especially important in oil refining standards, where clarity often serves as an indicator of purity and refinement. Additionally, BE195A supports eco-friendly oil refining by allowing for efficient processing without the need for harsh chemicals, which can be both costly and environmentally damaging.

Another key benefit is its versatility. BE195A is well-suited for both food-grade oil treatment and industrial oil purification, making it a flexible solution across different industries. Its use extends beyond edible oils to applications involving industrial oil purification, where maintaining clarity and quality are equally important. This versatility means that whether you’re refining vegetable oils or working with specialized industrial oils, BE195A provides a reliable, effective solution for oil decolorization.

Benefits of Using BE195A for Oil Decolorization

| Benefit | Explanation |

|---|---|

| High Adsorption Capacity | Effectively removes a range of impurities, including pigments and heavy metals |

| Eco-Friendly | Made from natural clay, supporting sustainable and responsible refining practices |

| Versatile Applications | Suitable for a variety of oils, including food-grade and industrial oils |

| Cost Savings | Lowers operational costs by reducing the need for repeated filtration |

| Improved Quality | Results in clear, high-quality oils that meet consumer and regulatory standards |

Achieving Oil Refining Standards with BE195A Bleaching Earth

Meeting industry standards is essential, and BE195A helps achieve these benchmarks with ease. Oil refining standards are designed to ensure that oils are safe, stable, and of the highest quality. BE195A supports these standards by providing effective clay-based oil decolorization, which removes contaminants and maintains oil purity. This makes it particularly valuable for refining vegetable oils, where clarity and purity are non-negotiable.

The market also demands consistency, particularly in edible oils where color and appearance can influence consumer decisions. BE195A meets these demands by ensuring that oils are refined to a level that satisfies both regulatory requirements and consumer expectations. In a world where oil color enhancement can determine market success, BE195A Bleaching Earth is a dependable tool for achieving the desired color and clarity every time.

Sustainable Oil Processing with Clay-Based Decolorization

Sustainability is increasingly important in oil processing, and BE195A supports these goals. As a clay-based oil decolorization solution, BE195A minimizes the need for synthetic chemicals and promotes sustainable oil processing. This not only reduces the environmental impact of oil refining but also aligns with growing consumer demand for eco-friendly products. By using natural clay, BE195A helps reduce waste and supports responsible oil refining practices.

I’ve seen firsthand how BE195A can transform oil processing from a resource-heavy operation to one that is more sustainable and efficient. Compared to chemical-based methods, BE195A’s clay-based approach supports a greener refining process, benefiting both producers and the planet. For more on the sustainable aspects of bleaching clay, check out the details on Fuller’s Earth, a similar material known for its eco-friendly properties.

Sustainability is increasingly important in industrial processes, and BE195A Bleaching Earth plays a significant role in promoting eco-friendly practices. Made from natural clay, BE195A supports a reduction in chemical waste and facilitates oil recycling, which aligns well with sustainability goals. I’ve seen firsthand how using BE195A allows companies to reclaim oils for reuse, minimizing waste and reducing the need for fresh resources. This not only lowers the carbon footprint of oil processing but also meets the growing consumer demand for sustainable products. The shift to using BE195A is a step towards greener practices in industrial oil treatment.

Practical Tips for Using BE195A in Oil Decolorization

To get the best results from BE195A, here are a few practical tips for oil decolorization. Start by storing BE195A in a dry, cool place to preserve its adsorptive properties. When determining the dosage, consider the type of oil and the level of contaminants present. Accurate dosage ensures that the clay effectively removes impurities without wasting material. Uniform mixing is also crucial, as it allows BE195A to interact evenly with the oil, providing consistent results.

Throughout the process, monitor the oil’s clarity and quality to gauge the effectiveness of the decolorization. Regular checks will help you maintain high standards and adjust the process if necessary. In my experience, following these tips can make a significant difference, ensuring that you achieve the clarity and quality needed for both food-grade oil treatment and industrial applications.

Oil Decolorization Techniques Compared

| Method | Adsorption Efficiency | Environmental Impact | Cost | Applications |

|---|---|---|---|---|

| BE195A Bleaching Earth | High | Eco-friendly | Cost-effective | Edible and industrial oil decolorization |

| Chemical Decolorization | Medium | Potentially harmful | Moderate to high | Industrial applications requiring chemicals |

| Activated Carbon | Moderate | Environmentally sound | High | Specialized oil filtration |

| Filtration with Synthetic Media | Variable | High waste output | Moderate to high | Limited by specific contaminants |

BE195A is a game-changer in terms of cost-effectiveness and operational efficiency. Its high adsorption capacity means that less material is needed to achieve optimal purification, which cuts down on both time and costs associated with multiple treatment cycles. In my experience, using BE195A has significantly reduced our processing expenses, as we can maintain high standards with fewer resources. This efficiency also contributes to better profit margins, making BE195A not just a choice for quality, but a financially smart investment for industrial oil processors looking to improve their bottom line.

Frequently Asked Questions

What is oil decolorization, and why is it important in refining?

Oil decolorization removes unwanted pigments and impurities, improving oil clarity and overall quality. This process is essential for both edible oil refining and industrial oil purification, ensuring oils meet consumer and regulatory standards.

How does BE195A Bleaching Earth work in oil decolorization?

BE195A uses activated clay to adsorb and remove contaminants from oils, including pigments, metals, and other impurities. This process improves the oil’s color and quality, making it more suitable for various applications.

What types of oils can benefit from BE195A Bleaching Earth?

BE195A is versatile and can be used for a variety of oils, including vegetable oils like soybean, canola, and palm oil. It is also effective in industrial oil purification, making it suitable for diverse refining needs.

Why is removing pigments from oil important?

Pigments can affect the oil’s color and visual appeal, which is crucial for food-grade oil treatment. Removing these pigments ensures that oils are clear and meet oil color enhancement standards for both consumers and industry.

Is BE195A environmentally friendly?

Yes, BE195A supports eco-friendly oil refining. Made from natural clay, it minimizes the need for harsh chemicals and promotes sustainable oil processing, reducing the overall environmental impact.

How does BE195A contribute to improving oil quality?

By effectively removing contaminants from oils, BE195A enhances clarity, stability, and shelf life, ensuring high-quality results in both edible and industrial applications.

What are some common contaminants removed by BE195A?

BE195A can remove heavy metals, free fatty acids, oxidation byproducts, and sulfur compounds, in addition to pigments. This makes it highly effective in refining contaminants in oil and improving overall oil purity.

How does BE195A compare to chemical oil decolorization methods?

BE195A offers a natural, clay-based oil decolorization method, which is generally more eco-friendly and cost-effective than chemical alternatives. It also supports sustainable processing by reducing chemical waste.

What is the role of activated clay in oil purification?

Activated clay, like BE195A, has a high adsorption capacity that captures impurities, enhancing oil purification. This is a crucial component in bleaching earth applications, allowing for efficient and effective refining.

Does BE195A meet oil refining standards for edible oils?

Yes, BE195A is designed to comply with oil refining standards, ensuring that edible oils treated with it are safe, clear, and of high quality. It is effective in producing oils that meet industry and regulatory guidelines.

How does BE195A improve the efficiency of oil filtration?

BE195A enhances efficient oil filtration by reducing the need for repeated filtering cycles. Its high adsorption ability captures impurities in one step, making the process faster and more effective.

Can BE195A be used in sustainable oil processing?

Absolutely. BE195A supports sustainable oil processing by reducing reliance on synthetic chemicals and facilitating oil recycling. This makes it a green choice for refining practices that prioritize environmental responsibility.

How does BE195A impact the flavor and stability of edible oils?

By removing contaminants from oils, BE195A helps preserve the natural flavor and stability of edible oils. This is particularly important in vegetable oils where taste and shelf life are key quality factors.

What advantages does BE195A offer in refining vegetable oils?

BE195A is particularly effective in refining vegetable oils, as it removes pigments and contaminants that can affect quality. It produces clear, pure oils that meet consumer expectations and industry standards.

How should BE195A be applied for the best oil decolorization results?

To maximize results, BE195A should be evenly mixed with the oil, and the dosage should be adjusted based on the oil’s impurity level. Proper mixing and dosage ensure effective decolorization and consistent quality.

How does BE195A handle oxidation byproducts in oils?

BE195A captures oxidation byproducts, which helps prevent rancidity and spoilage. This contributes to improving oil quality and extends the oil’s freshness, making it suitable for long-term storage.

Is BE195A suitable for food-grade oil treatment?

Yes, BE195A is ideal for food-grade oil treatment. Its natural, clay-based composition is safe and effective for refining oils intended for consumption, ensuring they are free from harmful contaminants.

Can BE195A support industrial oil purification?

BE195A is highly adaptable and can be used in both industrial oil purification and food-grade applications. Its effectiveness in removing various contaminants makes it versatile across different oil types.

What are some practical tips for using BE195A in oil decolorization?

Ensure proper storage, measure dosage accurately, and mix thoroughly for best results. Regularly monitor the oil’s clarity and quality during processing to maintain consistent outcomes.

Where can I purchase BE195A Bleaching Earth for oil decolorization?

BE195A Bleaching Earth is available through specialized suppliers, such as SSE, which provides options tailored for both edible and industrial oil applications.

Conclusion

When it comes to oil decolorization, BE195A Bleaching Earth provides a reliable, efficient, and eco-friendly solution. By removing pigments and impurities, BE195A elevates the quality of oils, making them suitable for various applications in both the edible and industrial sectors. Its ability to meet oil refining standards and support sustainable processing makes it a standout choice for anyone looking to enhance the clarity and purity of their oils.

If you’re interested in seeing how BE195A can improve your oil refining process, take a look at our Bleaching Earth products for more details. For those in the food industry, you may also find value in our related post on How BE195A Supports the Bleaching Earth Food Industry: From Purity to Profit. To explore bleaching earth’s broader uses, visit our cornerstone page A Complete Guide to Bleaching Earth. With BE195A, achieving optimal oil clarity and sustainability has never been easier.

Disclaimer: This article is for informational purposes only. Consult a professional before implementing any new oil purification methods.

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้