Hydrocarbon Separation and Refining: How Molecular Sieves Enhance Fuel Quality

| Aspect | Description | Benefit |

|---|---|---|

| Hydrocarbon Separation | Molecular sieves separate hydrocarbons by adsorbing specific molecules based on size and shape. | Enhances purity, supports cleaner fuel production. |

| Adsorption Performance | Efficient adsorption of unwanted hydrocarbons such as sulfur compounds and aromatic hydrocarbons. | Improves fuel quality, reduces contaminants. |

| Temperature Impact | Zeolites like MOR, MFI, and CON perform differently at varying temperatures, affecting adsorption and diffusion. | Allows for optimized molecular sieve selection based on application conditions. |

| Emission Control | Reduces hydrocarbon emissions during cold start in gasoline engines, as studied in automotive research. | Supports environmental compliance, lowers emissions in refining processes. |

| Molecular Sieve Versatility | Effective in multiple refining applications including isomerization and catalytic support. | Versatile solutions for diverse fuel refining needs. |

| Long-Term Cost Benefits | Molecular sieves are reusable with proper regeneration, making them cost-effective in continuous refinery operations. | Lowers operational costs, extends molecular sieve life. |

Table Of Contents

“Hydrocarbon Separation and Refining are key to producing cleaner, high-quality fuels. Molecular sieves maximize this process, transforming complex hydrocarbons into fuel with enhanced purity and efficiency.”

Introduction

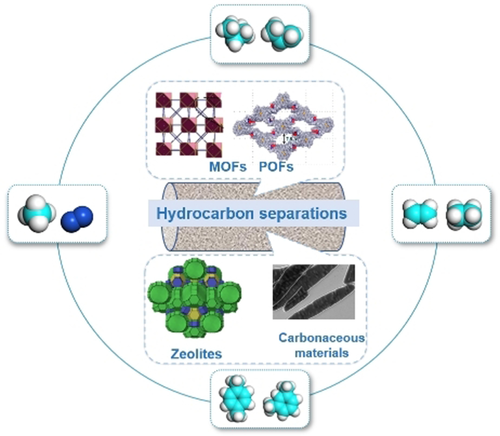

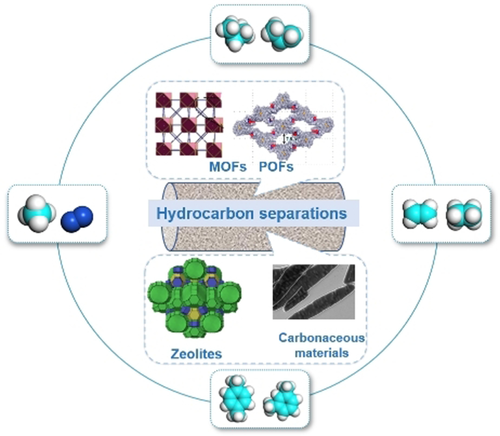

The process of Hydrocarbon Separation and Refining has become increasingly important as global demand for cleaner and more efficient fuels grows. One of the most effective tools in this process is the use of molecular sieves, particularly zeolites, which are highly effective in separating hydrocarbons and enhancing fuel quality. Molecular sieves can selectively adsorb different types of molecules, making them valuable in the removal of impurities, reduction of emissions, and improvement of fuel performance.

For an overview of how molecular sieves serve in diverse applications, visit our Comprehensive Guide to Molecular Sieves.

The Role of Molecular Sieves in Hydrocarbon Separation

| Zeolite Type | Adsorbed Molecule | Primary Use in Refining | Selectivity |

|---|---|---|---|

| MFI | Ethylene | Fuel purity, ethylene separation | High selectivity for VOCs |

| CON | Benzene | Aromatic hydrocarbon separation | High affinity for aromatics |

| MOR | Propane | Branched and linear hydrocarbon mix | Versatile for larger molecules |

Hydrocarbon separation using molecular sieves relies on these materials’ ability to selectively adsorb molecules based on size, shape, and polarity. This selectivity is especially useful in separating complex hydrocarbon mixtures in fuel refining. By using specific zeolite types, refineries can achieve high-purity outputs that meet strict fuel quality standards.

Zeolites like MFI, MOR, and CON play distinct roles based on their pore structure and adsorption properties. For example, MFI zeolites are particularly effective for adsorbing ethylene, whereas CON zeolites are more suitable for benzene molecules due to their strong adsorption affinity. This specificity allows refineries to target and isolate different hydrocarbons effectively.

For a deeper understanding of various applications, see our Key Molecular Sieve Processes: Applications and Industry Impact.

Enhancing Fuel Quality with Molecular Sieves

| Benefit | Description | Result |

|---|---|---|

| Sulfur Removal | Adsorbs sulfur compounds for cleaner combustion | Reduced sulfur emissions |

| Volatile Organic Compound (VOC) Control | Traps VOCs, especially at low temperatures | Improved air quality, reduced VOC levels |

| Increased Combustion Efficiency | Removes impurities that hinder fuel performance | Enhanced fuel quality and efficiency |

The ability of molecular sieves to purify fuel by adsorbing impurities is one of the reasons they are so widely used in fuel refining. By removing unwanted compounds like sulfur, nitrogen, and aromatics, molecular sieves help produce cleaner and more efficient fuels.

The adsorption performance of molecular sieves at different temperatures further enhances fuel quality. Research has shown that zeolites like MFI have a high adsorption capacity for ethylene at low temperatures, making them ideal for controlling volatile organic compounds (VOCs) in gasoline engines, especially during cold starts. This capability is critical for both hydrocarbon purification and reducing harmful emissions, making molecular sieves environmentally beneficial as well as effective in refining processes.

For scientific insights on hydrocarbon capture using zeolites, visit this study on the Effects of Zeolite Molecular Sieve on Hydrocarbon Adsorbent and Diffusion Performance.

“Molecular sieves are transforming fuel production by creating high-purity fuels, ensuring cleaner combustion and meeting today’s rigorous environmental standards.”

Applications of Molecular Sieves in Petrochemical Processes

| Process | Application of Molecular Sieves | Outcome |

|---|---|---|

| Isomerization | Converts straight-chain to branched hydrocarbons | Produces high-octane fuel |

| Hydrocarbon Purification | Adsorbs specific contaminants | High-purity hydrocarbon streams |

| Catalytic Support | Stabilizes catalysts in high-temperature reactions | Boosts catalyst efficiency and longevity |

Molecular sieves play a multifaceted role in petrochemical processes, including isomerization, hydrocarbon purification, and catalytic support. Each of these applications enhances the performance and efficiency of fuel production.

- Isomerization

- In the isomerization process, molecular sieves facilitate the rearrangement of straight-chain hydrocarbons into branched chains. This conversion is crucial for producing high-octane fuels, as branched hydrocarbons burn more efficiently than straight-chain ones. The 5A molecular sieve is particularly suited to this process, offering high selectivity and efficiency.

- Hydrocarbon Purification

- In the removal of impurities, molecular sieves selectively adsorb contaminants, leaving behind high-quality hydrocarbon streams. This purification step is essential in meeting environmental and performance standards in fuel refining.

- Catalytic Support

- Molecular sieves also serve as catalyst supports, providing a stable surface for catalytic reactions that can further improve fuel quality. This role is especially important in cracking and other high-temperature refining processes where stability and reactivity are key.

These diverse applications make molecular sieves indispensable in fuel refining, optimizing everything from fuel combustion to long-term storage stability.

Advantages of Using Molecular Sieves in Refining

| Advantage | Description | Impact |

|---|---|---|

| Fuel Purity | Molecular sieves remove sulfur, VOCs, and aromatics | Enhances fuel quality and performance |

| Cost Efficiency | Regeneration extends the usable life of molecular sieves | Reduces long-term refining costs |

| Environmental Compliance | Captures pollutants, meeting stricter regulations | Aligns with sustainability and emissions standards |

The advantages of using molecular sieves in refining are numerous, ranging from enhanced fuel quality to reduced operational costs. Here are some key benefits:

- Improved Fuel Quality: By removing impurities like sulfur and VOCs, molecular sieves improve the combustion quality of fuels, leading to higher efficiency and lower emissions.

- Operational Efficiency: Molecular sieves contribute to streamlined refining operations by reducing the need for extensive purification processes, which saves time and energy.

- Environmental Compliance: By capturing harmful hydrocarbons and VOCs, molecular sieves help refineries meet stringent environmental standards, supporting sustainability in the industry.

- Cost-Effectiveness: Molecular sieves are reusable through regeneration processes, which minimizes the need for frequent replacements and lowers long-term operational costs.

These advantages are not only beneficial for refinery efficiency but also align with environmental sustainability goals, making molecular sieves a preferred choice in hydrocarbon separation and refining.

Explore our Molecular Sieves Product List to find high-quality sieves for various refining applications.

Case Study: Molecular Sieve Application in Refining

| Hydrocarbon | Zeolite Type | Adsorption Capacity | Refining Application |

|---|---|---|---|

| Ethylene | MFI | High | VOC removal and fuel purity |

| Benzene | CON | Very high | Aromatic compound separation |

| Propane | MOR | Moderate | Mixed hydrocarbon and branched-chain separation |

A notable application of molecular sieves in refining involves their use in separating benzene and ethylene, two hydrocarbons essential in fuel production. In a recent study, the performance of MFI, MOR, and CON molecular sieves was compared for adsorbing these hydrocarbons. MFI was particularly effective for ethylene, showing a high adsorption capacity at lower temperatures. CON, on the other hand, was more effective for benzene, displaying high adsorption and a strong affinity for aromatic hydrocarbons.

This example illustrates how selecting the right molecular sieve type can optimize refining processes, leading to higher fuel quality and efficiency. By choosing molecular sieves tailored to specific hydrocarbons, refineries can achieve more precise separations and improve the overall quality of their outputs.

Future Trends in Molecular Sieves for Fuel Refining

| Trend | Description | Potential Impact |

|---|---|---|

| Advanced Regeneration | More efficient regeneration methods for longer molecular sieve life | Reduces costs and environmental impact |

| Tailored Pore Engineering | Customized pore sizes for specific hydrocarbons | Improves refining precision and efficiency |

| Integration with Clean Fuels | Supports biofuel and synthetic fuel refinement | Contributes to cleaner, renewable energy |

As the fuel industry faces growing environmental challenges, the role of molecular sieves is expected to expand. Future developments include:

- Enhanced Regeneration Techniques: Improved methods for regenerating molecular sieves will extend their lifespan and reduce waste.

- Customizable Molecular Sieves: Advances in molecular engineering could lead to zeolites with tailor-made pore sizes, improving their ability to separate specific hydrocarbons.

- Integration with Renewable Energy: As clean energy technology advances, molecular sieves may play a role in purifying biofuels and synthetic fuels, supporting a sustainable fuel transition.

These trends indicate a promising future for molecular sieves in refining, as they continue to adapt to industry needs and environmental standards.

Frequently Asked Questions

What is hydrocarbon separation?

Hydrocarbon separation is the process of isolating specific hydrocarbons from a mixture, often for refining purposes to improve fuel quality.

What are molecular sieves used for in refining?

Molecular sieves are used to separate hydrocarbons, purify fuels, and remove impurities like sulfur, enhancing fuel quality and efficiency.

How do molecular sieves improve fuel quality?

By adsorbing impurities, molecular sieves help produce cleaner-burning, high-quality fuels that comply with environmental standards.

What hydrocarbons can molecular sieves separate?

Molecular sieves can separate various hydrocarbons, including benzene, ethylene, and propane, based on molecule size and shape.

How do molecular sieves reduce sulfur in fuel?

Molecular sieves adsorb sulfur compounds from fuel, helping to meet stringent emissions standards and improve combustion.

What role do molecular sieves play in isomerization?

In isomerization, molecular sieves act as catalyst supports, enabling conversion of straight-chain to branched-chain hydrocarbons for higher octane ratings.

How do molecular sieves compare to silica gel in refining?

Molecular sieves offer higher selectivity and efficiency for hydrocarbon separation and adsorption, especially in removing impurities.

Can molecular sieves be regenerated in refining processes?

Yes, molecular sieves can be regenerated by heating or using a vacuum to restore adsorption capacity, extending their operational life.

What are VOCs, and how do molecular sieves handle them?

Volatile Organic Compounds (VOCs) are pollutants. Molecular sieves adsorb VOCs, especially during cold starts, reducing emissions.

Why are molecular sieves critical for hydrocarbon purity?

By capturing impurities, they ensure only high-purity hydrocarbons are present, which is vital for quality control in fuel production.

How does temperature affect molecular sieve performance?

Low temperatures enhance adsorption for some hydrocarbons, while high temperatures can increase diffusion rates, affecting performance.

How do molecular sieves contribute to emission control?

Molecular sieves capture harmful hydrocarbons, helping refineries meet emissions regulations and contribute to cleaner air.

What is the role of molecular sieves in catalytic cracking?

In catalytic cracking, molecular sieves act as supports that stabilize catalysts, aiding in breaking down larger hydrocarbon molecules.

What advantages do molecular sieves offer in refining?

They improve fuel quality, support environmental compliance, and reduce operational costs through efficient adsorption and regeneration.

How are molecular sieves selected for specific hydrocarbons?

Selection depends on pore size, hydrocarbon type, and application requirements, ensuring optimal separation and adsorption.

Can molecular sieves be used for other gases in refining?

Yes, molecular sieves also separate gases like nitrogen and carbon dioxide, essential for some refining processes.

What types of impurities do molecular sieves target in fuel refining?

Common impurities include sulfur compounds, water, nitrogen, and aromatic hydrocarbons, all of which molecular sieves can adsorb.

Do molecular sieves help in controlling moisture in fuel?

Yes, molecular sieves efficiently remove moisture from fuels, preventing corrosion and ensuring quality during storage and transport.

What is the environmental impact of molecular sieve use in refineries?

Molecular sieves reduce harmful emissions, helping refineries comply with environmental standards and reduce pollution.

Where can I find molecular sieves for refining applications?

Check our Molecular Sieves Product List to find the right type for your refining needs.

“Through precise adsorption technology, molecular sieves make hydrocarbon separation not just efficient but essential—delivering fuels that are both powerful and sustainable.”

Conclusion

Molecular sieves are indispensable in hydrocarbon separation and refining, playing a vital role in producing high-quality, cleaner-burning fuels. Their versatility in separating hydrocarbons, purifying fuel, and supporting catalytic reactions makes them essential tools in the petrochemical industry. Moreover, their reusability and efficiency in capturing harmful hydrocarbons contribute to environmental sustainability, aligning with global efforts to reduce emissions.

For a comprehensive range of molecular sieves suited to refining and other applications, explore our Molecular Sieves Product List. Each product is designed to meet the high standards of the refining industry, ensuring quality, efficiency, and compliance. To learn more about molecular sieve processes across various sectors, visit our A Comprehensive Guide to Molecular Sieves, or read our previous post Adsorption Solutions with Molecular Sieves: Targeting VOCs, Ammonia, and Sulfur Compounds.

By understanding and leveraging the unique capabilities of molecular sieves, refineries can enhance fuel quality and operate more sustainably, meeting both industry demands and environmental regulations effectively.

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้