PureSorb GB-100E vs PureSorb WB100

| Key Feature | PureSorb GB-100E | PureSorb WB100 |

|---|---|---|

| Material Base | Bituminous | Coal |

| Form | Extruded (2 mm) | Granular (8×30 mesh) |

| Application Focus | Gas Adsorption | Water Purification |

| Ideal Use | Air purification, solvent recovery | Water dechlorination, organic contaminants removal |

| Adsorption Capacity | High | High |

Table Of Contents

“Activated carbon is more than just a filtration tool—it’s the difference between clean, breathable air and polluted environments, making it a vital solution across industries.”

Introduction: Understanding Activated Carbon

Activated carbon might seem like a niche topic, but if you’re in industries involving air or water purification, it’s a game changer you can’t afford to overlook. Whether you’re tackling air pollution, industrial solvent recovery, or purifying drinking water, activated carbon’s porous structure offers an efficient solution for trapping impurities.

In this blog post, I’ll be focusing specifically on PureSorb GB-100E vs PureSorb WB100, two standout products in the activated carbon market. Both have unique properties that suit different applications, and understanding these differences can make all the difference in achieving the best results for your project. My goal is to make this comparison accessible and engaging while providing the insights you need to make an informed choice.

A Quick Overview of Activated Carbon

Before we dive into the differences, let’s make sure we’re all on the same page about what activated carbon really is and why it matters. Activated carbon is a form of carbon that’s been processed to create countless tiny pores that increase its surface area, making it extremely effective at adsorbing impurities from gases and liquids.

Activated carbon can come from various sources, such as coal, coconut shells, and bituminous material. Its unique ability to remove organic contaminants, bad tastes, and odors makes it a popular choice in applications ranging from municipal water treatment to industrial air purification. Whether it’s activated carbon for gas adsorption or activated carbon for water purification, understanding the different material bases—like bituminous vs coal-based carbon—can help you choose the right product for your needs.

Activated Carbon Applications

| Application Type | Activated Carbon Form | Benefits |

|---|---|---|

| Air Purification | Extruded (e.g., GB-100E) | Low-pressure drop, efficient airflow |

| Water Purification | Granular (e.g., WB100) | High contact area, effective contaminant removal |

| Solvent Recovery | Extruded | Durable and reliable for gas treatment |

| Household Use | Granular | Easy to handle, effective for small-scale applications |

| Industrial Emissions | Both extruded and granular | Depends on the desired outcome and system requirements |

What Makes PureSorb GB-100E and WB100 Special?

Both PureSorb GB-100E and PureSorb WB100 are top-tier activated carbon products, but what sets them apart is their structure and source material. GB-100E is an extruded activated carbon made from bituminous coal, which gives it a cylindrical form with a fixed diameter of 2 mm. On the other hand, WB100 is a granular activated carbon derived from a coal base, with particle sizes ranging between 0.6 mm to 2.36 mm (8×30 mesh).

The main difference between these two is how they are best used. The extruded form of GB-100E offers uniformity, which is ideal for applications requiring consistent airflow, such as in air purification systems. Conversely, the granularity of WB100 makes it versatile for both air and water applications, allowing greater contact efficiency when used in liquid phase treatments.

PureSorb GB-100E vs PureSorb WB100

| Feature | PureSorb GB-100E | PureSorb WB100 |

|---|---|---|

| Material Base | Bituminous | Coal |

| Physical Form | Extruded | Granular |

| Mesh Size | 2 mm | 8×30 mesh (0.6 – 2.36 mm) |

| Adsorption Capacity | High | High |

| Applications | Gas adsorption, air purification | Water purification, organic contaminants removal |

| Durability | Excellent resistance to abrasion | High, but slightly less than extruded forms |

| Pressure Drop | Minimal | Moderate |

| Suitable For | Air treatment, gas adsorption | Water treatment, organic pollutants removal |

Extruded vs. Granular: Why Structure Matters

If you’ve ever wondered why some activated carbons are extruded while others are granular, this section is for you. Extruded activated carbon, like PureSorb GB-100E, is shaped into cylindrical pellets, giving it high mechanical strength and a lower pressure drop during gas flow. This makes it particularly suitable for activated carbon for gas adsorption applications, where airflow efficiency is crucial.

Advantages of Extruded Activated Carbon (GB-100E)

- Consistent cylindrical form ensures reliable airflow.

- Low-pressure drop across filtration beds.

- High resistance to mechanical abrasion.

- Suitable for air purification and gas-phase processes.

- Reduced operational costs due to durability.

On the other hand, granular activated carbon (GAC), such as PureSorb WB100, is more irregular in shape. This structure allows it to create more contact points in liquid, making it particularly effective for water purification tasks. Its granular form is great for filtering out chlorine or other contaminants in water systems, offering both effectiveness and adaptability in a wide variety of treatment setups.

Advantages of Granular Activated Carbon (WB100)

- Irregular shape provides greater surface contact in liquids.

- Ideal for applications like water purification.

- Versatility in both air and liquid phase processes.

- Efficient removal of organic contaminants.

- Easy handling and deployment in filtration systems.

A common misconception I frequently encounter is the belief that extruded and granular activated carbon can be interchanged without considering the implications on performance. Many users think that as long as adsorption capacity is similar, the form doesn’t matter—this couldn’t be further from the truth. Granular carbon like WB100 is incredibly effective in liquid filtration, where maximizing contact area is essential. However, when used in gas-phase adsorption without recognizing its higher pressure drop, the efficiency can plummet. It’s these misconceptions about the importance of physical form that can lead to suboptimal results in gas purification systems.

Extruded, Granular, and Powdered: Different Forms of Activated Carbon

Extruded Activated Carbon

Extruded activated carbon, like PureSorb GB-100E, is created by combining powdered activated carbon with a binder and forming it into cylindrical shapes. This form provides mechanical strength and a consistent diameter, making it ideal for gas-phase applications where uniform airflow is critical. The extruded shape also minimizes pressure drop, which is an important factor when choosing activated carbon for air purification and industrial gas treatment.

Granular Activated Carbon

Granular activated carbon (GAC), like PureSorb WB100, is made from larger, irregular granules that offer increased contact surface. This granular form makes it excellent for water purification and other liquid-phase applications, as the irregular shape enhances contact points, increasing adsorption efficiency. GAC is commonly used in systems requiring effective removal of chlorine, taste, and odor from water, as well as organic contaminants.

Powdered Activated Carbon (PAC)

Powdered activated carbon (PAC) is a very fine type of activated carbon with particle sizes less than 0.18 mm. This form is primarily used for liquid-phase applications where rapid adsorption is needed. PAC is typically added directly to liquids, making it effective for applications in water treatment plants to remove taste and odor or in the food and beverage industry to purify ingredients. Unlike extruded and granular forms, PAC provides a quick response but lacks the mechanical strength for continuous, fixed-bed operations.

How These Forms Apply to PureSorb GB-100E and WB100

While PureSorb GB-100E is available as an extruded activated carbon, making it a great choice for applications where consistent airflow is required, PureSorb WB100 is offered in a granular form, making it particularly effective for water treatment and organic contaminants removal. Each form of activated carbon—extruded, granular, and powdered—has its strengths, and choosing the right one depends on the specific requirements of the project. For instance, if a high mechanical strength and low pressure drop are needed, GB-100E is the ideal choice. If maximum surface area contact is essential for liquid treatment, WB100 would be more suitable.

Bituminous vs. Coal-Based Carbon: Understanding the Differences

Another key factor in choosing the right activated carbon is the material it’s made from. PureSorb GB-100E is produced from bituminous coal, while PureSorb WB100 is derived from a regular coal base. This difference in material significantly impacts the properties of each product, including adsorption capacity and mechanical durability.

Bituminous activated carbon, such as GB-100E, generally has higher hardness, which provides excellent resistance to abrasion. This feature is particularly important in industrial processes where the carbon may be subjected to a lot of movement or pressure. Conversely, WB100’s coal-based structure delivers similar adsorption performance but shines more in applications requiring versatility, such as liquid-phase decontamination or air and water treatment with activated carbon.

Comparison of Bituminous vs. Coal-Based Activated Carbon

| Property | Bituminous Carbon (GB-100E) | Coal-Based Carbon (WB100) |

|---|---|---|

| Hardness | High | Moderate |

| Adsorption Efficiency | Excellent | Very Good |

| Moisture Content | Low | Low |

| Typical Applications | Gas-phase processes | Liquid-phase processes |

Adsorption Applications: Where Each Product Shines

Now, let’s talk about what these activated carbons can actually do for you. PureSorb GB-100E is ideal for gas adsorption processes, thanks to its extruded form. It’s especially effective in applications like industrial air purification, where minimizing pressure drop while maintaining a high level of adsorption is crucial. Whether it’s an industrial setting or even reducing airborne contaminants in a public space, GB-100E is up to the task. It’s also great for solvent recovery in chemical industries, where its consistent structure ensures efficiency.

PureSorb WB100, on the other hand, is well-suited for water purification, dechlorination, and organic contaminants removal. Its granular structure maximizes contact area, making it highly efficient for use in municipal water filters or even in smaller-scale home systems. Imagine you’re running a beverage company that requires high-quality water—WB100 would be an excellent choice to ensure that your water remains free from unwanted impurities.

Adsorption Capabilities of GB-100E and WB100

| Parameter | GB-100E | WB100 |

|---|---|---|

| Organic Contaminants | Effective in gas adsorption | Excellent for liquid contaminants |

| Chlorine Removal | Moderate | High |

| Efficiency in Air Systems | High | Moderate |

| Efficiency in Water Systems | Moderate | High |

Choosing the Right Activated Carbon for Your Needs

So, how do you decide between GB-100E and WB100? It all comes down to what you need them to do. If your primary goal is gas adsorption with minimal pressure loss, then PureSorb GB-100E is your best bet. Its extruded form and high mechanical strength make it suitable for a wide range of gas-phase applications, ensuring you get reliable performance without the hassle of frequent replacement.

Common Misconceptions About Activated Carbon

- Assuming all activated carbons have identical adsorption efficiency.

- Believing that extruded and granular carbons are interchangeable.

- Overlooking the impact of pressure drop in gas-phase systems.

- Underestimating the importance of material base (bituminous vs. coal).

- Choosing the wrong form without considering specific application requirements.

However, if you’re looking at a project involving water purification—especially something that requires removing organic compounds or dechlorinating water—then PureSorb WB100 might be the better option. Its granular form and coal base give it the versatility needed for liquid treatments. It’s all about understanding the specific requirements of your project and picking the right tool for the job.

Practical Considerations in Choosing Activated Carbon

| Factor Considered | GB-100E | WB100 |

|---|---|---|

| Flow Rate | Low pressure drop (ideal for gas) | Slightly higher pressure drop (suitable for liquids) |

| Physical Durability | Very High (resistant to wear) | High (suitable for most applications) |

| Use Case | Air purification, solvent recovery | Water purification, dechlorination |

| Economic Value | Long-term use due to mechanical strength | Economical for large-scale water treatment |

For someone just starting out, my key piece of advice would be to truly understand the needs of the application—is it about gas adsorption with low resistance to airflow, or is it about purifying water with organic contaminants? If you’re dealing with gas treatment, GB-100E, with its extruded form, is an optimal choice for consistent airflow and long-term efficiency. For water treatment or organic contaminants removal, WB100, with its granular form and coal base, is a better fit, thanks to its enhanced contact surface area. Choosing between the two starts with recognizing the specific demands of the task at hand, rather than assuming that one type fits all applications.

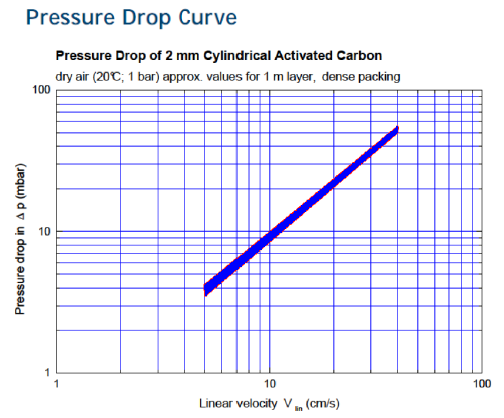

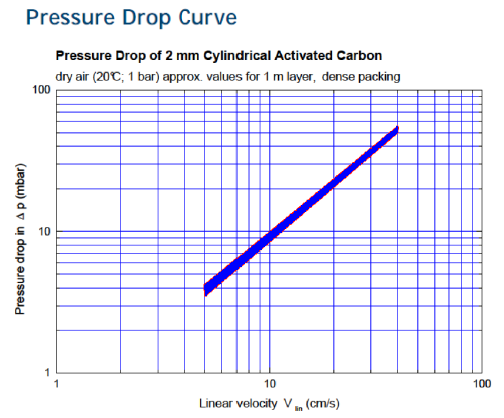

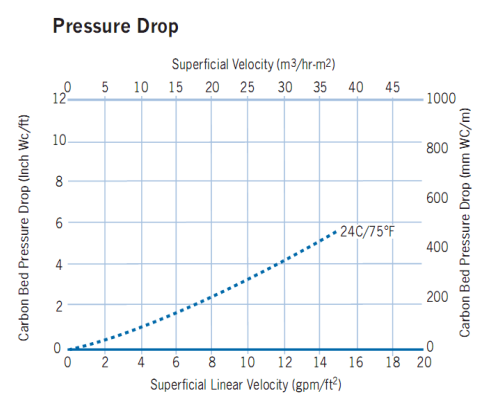

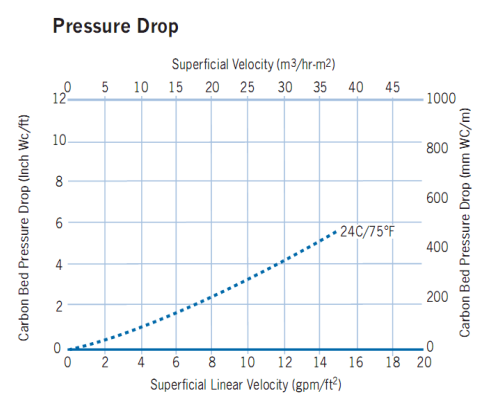

Pressure Drop: Why It Matters in Choosing Activated Carbon

Understanding Pressure Drop

When discussing activated carbon, especially for air and gas treatment, pressure drop is a critical concept. Pressure drop refers to the reduction in pressure as a fluid (air or liquid) flows through a medium, such as an activated carbon bed. In simpler terms, it’s the resistance that the activated carbon creates against the movement of the fluid. A higher pressure drop means that more energy is required to push the fluid through the system, leading to increased operational costs and inefficiencies.

In systems designed for air purification or gas adsorption, minimizing pressure drop is essential to ensure the process is both cost-effective and efficient. The form and particle size of activated carbon can significantly impact how much resistance is created during operation.

Comparing Pressure Drop: PureSorb GB-100E vs. WB100

PureSorb GB-100E, which comes in an extruded form, has a cylindrical structure that helps to create consistent pathways for gas or air to flow through. This results in a low pressure drop, making it highly efficient for air treatment applications. Because the cylindrical pellets are uniform, the flow of air or gas encounters less resistance, reducing the energy needed to maintain airflow. This makes GB-100E ideal for use in air purification and industrial gas treatment systems, where maintaining a steady flow without excessive energy use is crucial.

On the other hand, PureSorb WB100 is a granular activated carbon with an irregular shape, which naturally causes more turbulence and resistance when air or liquid passes through it. This higher pressure drop can be advantageous in some water treatment applications where increased contact time between the activated carbon and the fluid is desired. However, in air or gas systems, the higher pressure drop can lead to greater energy consumption and increased operational costs compared to GB-100E. Therefore, WB100 is more suited to liquid-phase applications where the goal is efficient adsorption rather than maintaining high flow rates.

Choosing the Right Product Based on Pressure Drop

If minimizing pressure drop and maintaining efficient airflow is crucial for your project—such as in an industrial air filtration system—PureSorb GB-100E is the best option. Its extruded form provides uniformity, allowing for smooth flow with minimal resistance. For projects where liquid treatment and maximum contact are key, and where pressure drop is not a primary concern, PureSorb WB100 offers the irregular structure needed for efficient contaminant adsorption.

What I’ve Learned About Using Activated Carbon

I’ve worked with both of these products, and here’s what I’ve learned from my own experiences. When using PureSorb GB-100E for a large-scale air purification project, I found its extruded shape to be incredibly effective at maintaining consistent airflow, which was crucial in minimizing energy consumption. The uniformity of the product also meant less frequent replacement, ultimately cutting down on long-term operational costs.

On the other hand, PureSorb WB100 really shone during a water treatment application I worked on. The granular form was perfect for creating a high contact surface area, allowing for efficient removal of contaminants in the water stream. Its versatility and ease of use in both liquid and gas phases make it a go-to option for projects needing that extra bit of adaptability.

In one particular air purification project, I initially opted for PureSorb WB100 due to its versatile granular form. However, as the project progressed, I realized that the increased pressure drop and the lower airflow efficiency were hampering our objectives. Switching to PureSorb GB-100E, with its extruded structure and bituminous base, made a significant difference—streamlining the air passage while maintaining high adsorption efficiency. This experience taught me that for projects involving consistent airflow, the extruded form really shines by reducing operational inefficiencies, and the material base can greatly impact durability.

Frequently Asked Questions

What is the difference between PureSorb GB-100E and WB100?

PureSorb GB-100E is an extruded activated carbon made from bituminous coal, while WB100 is a granular activated carbon derived from a coal base. GB-100E is cylindrical, making it suitable for gas-phase applications, whereas WB100’s granular form is better for liquid-phase applications like water purification.

When should I choose PureSorb GB-100E over WB100?

Choose GB-100E for gas adsorption tasks, especially when low pressure drop is important, such as in industrial air purification systems. Its extruded form ensures efficient airflow with minimal resistance.

What are the main uses of PureSorb WB100?

WB100 is ideal for water purification, dechlorination, and organic contaminants removal. Its granular form allows for high surface area contact, making it suitable for removing impurities from both liquids and gases.

What does “extruded vs. granular activated carbon” mean?

Extruded activated carbon (like GB-100E) is shaped into cylindrical pellets that are mechanically strong and have a consistent diameter, reducing pressure drops in gas flows. Granular activated carbon (such as WB100) has an irregular shape that creates high surface area for liquid contact, making it effective in water purification.

What makes bituminous carbon different from coal-based carbon?

Bituminous carbon (used in GB-100E) tends to have higher hardness and more durable structure, which is important for resisting abrasion in gas-phase processes. Coal-based carbon (as in WB100) also has high adsorption capacity, but it’s better suited for water treatment applications.

Which activated carbon is best for air purification?

GB-100E is ideal for air purification applications due to its extruded structure, which provides efficient airflow with minimal pressure resistance.

How effective is PureSorb WB100 in water purification?

WB100 is highly effective in water purification. Its granular form is excellent for maximizing contact area with liquid, making it suitable for removing chlorine and other organic contaminants.

Can PureSorb GB-100E be used for water treatment?

While GB-100E can technically be used for water treatment, it’s better suited for gas-phase applications due to its extruded form. WB100 is more effective for treating liquids.

What industries benefit most from using PureSorb GB-100E?

GB-100E is highly beneficial for industries requiring gas adsorption, such as chemical processing, industrial air purification, and solvent recovery.

What are some typical applications of PureSorb WB100?

WB100 is used for a range of applications, including water purification, removing organic contaminants, and treating industrial wastewater. It’s also suitable for household water filters.

How does the particle size of GB-100E impact its use?

The 2 mm extruded particle size of GB-100E provides consistent airflow and reduces pressure drop, making it ideal for air and gas treatment systems that require stable performance.

What is the benefit of using granular activated carbon like WB100?

The granular form of WB100 provides an increased contact surface, which is particularly beneficial for water purification. It ensures efficient removal of impurities and contaminants.

Can both PureSorb GB-100E and WB100 be used in air treatment?

Yes, both can be used, but GB-100E is specifically designed for air treatment due to its extruded form, which allows for better airflow with low resistance, making it more efficient than WB100 for this purpose.

How do I choose between PureSorb GB-100E and WB100 for my project?

Consider the type of application: use GB-100E for gas adsorption where efficient airflow is needed, and WB100 for water purification where a larger contact surface is required for efficient contaminant removal.

What are the main GB-100E features that set it apart?

GB-100E features extruded cylindrical pellets, high mechanical strength, and efficient adsorption capacity for gas-phase contaminants, making it ideal for air purification and industrial emissions control.

Why is activated carbon used for organic contaminants removal?

Activated carbon has a high adsorption capacity due to its porous structure, which traps organic contaminants. Both GB-100E and WB100 are effective for this, but the best choice depends on whether the contaminants are in gas or liquid form.

How does pressure drop impact the choice between extruded and granular activated carbon?

Extruded activated carbon, like GB-100E, has a lower pressure drop, which is beneficial for gas flow applications. In contrast, granular activated carbon like WB100 may experience a slightly higher pressure drop, which can be acceptable in liquid-phase processes where high surface area is critical.

What are some PureSorb activated carbon uses that highlight its versatility?

PureSorb activated carbon can be used for air purification, water treatment, solvent recovery, and industrial emissions control. GB-100E is best for consistent gas-phase adsorption, while WB100 excels in liquid-phase applications.

Is PureSorb WB100 suitable for both industrial and residential uses?

Yes, WB100 is versatile enough for both industrial and residential applications. It can be used in municipal water treatment facilities as well as household water filters to remove impurities like chlorine and organic contaminants.

How do GB-100E and WB100 contribute to air and water treatment with activated carbon?

GB-100E contributes to air treatment by providing efficient gas adsorption with minimal resistance, ideal for capturing airborne contaminants. WB100 supports water treatment by offering high surface contact, efficiently removing organic contaminants from liquids, making both valuable depending on the specific need.

Conclusion: Making the Final Choice

At the end of the day, choosing the right activated carbon product is about understanding your own needs. Whether you’re tackling air pollution, purifying drinking water, or treating wastewater, the differences between PureSorb GB-100E and PureSorb WB100—from material base to structural form—play a significant role in their effectiveness for your specific project. By considering your unique requirements, you can make an informed choice that will ensure the best outcomes.

Call to Action

If you’re still unsure which activated carbon is the best fit, feel free to reach out or leave a comment below. I’m here to help answer your questions and guide you in selecting the right product. For more information about activated carbon, check out our Activated Carbon category. And if you’re interested in exploring more about air purification, you might want to read The Benefits of Activated Carbon for Air Purification, or Maximizing Purity: The Benefits and Uses of Powdered Activated Carbon Made of Bamboo

PureSorb GB-100E: The Ideal Solution for Gas Adsorption and Air Purification

PureSorb WB100: The Ideal Solution for Water Purification and Organic Contaminant Removal

For further insights on activated carbon’s efficiency in real-world settings, take a look at Performance evaluation of activated carbon sorbents for indoor air purification during normal and wildfire events or our Comprehensive Guide to Activated Carbon 2024

Proper maintenance of adsorption media is essential to keep nitrogen generators performing at their best. Learn how molecular sieves and activated carbon filters work together to maintain high nitrogen purity and system reliability in our in-depth guide on Media Replacement and Servicing for PSA Nitrogen Systems. This article explains the complete process—from identifying performance decline to professional desiccant replacement—helping plant engineers and maintenance teams extend equipment life and reduce downtime.

Disclaimer

The information provided here is based on my experience and insights into activated carbon applications. Always consult with a professional before making any decisions that may impact industrial processes or safety standards.

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้