How Molecular Sieves Work

Table of Contents

I. Introduction to How Molecular Sieves Work

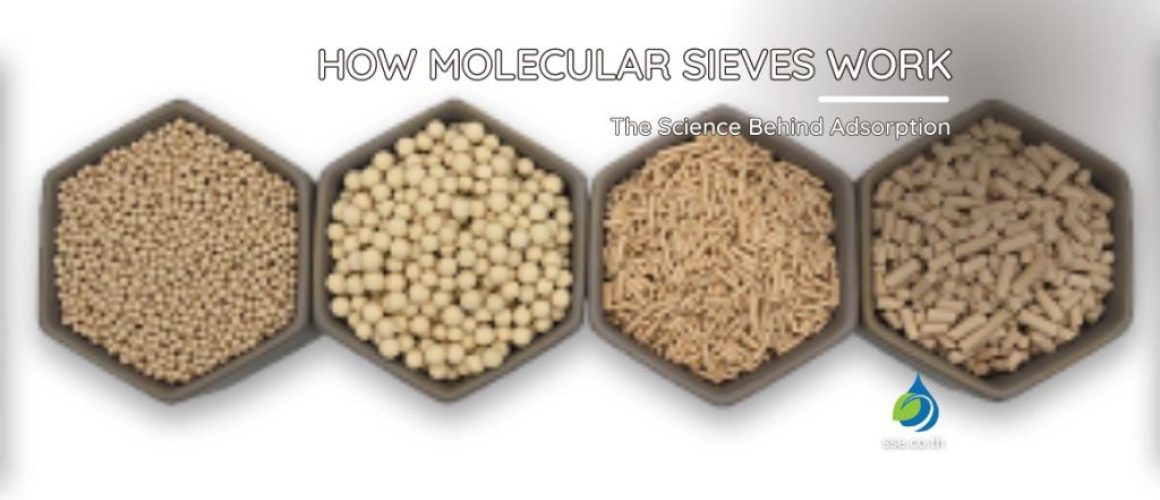

Molecular sieves are specialized adsorbent materials that have a wide range of applications in various industries. They play a crucial role in gas separation, purification, and drying processes. Understanding how molecular sieves work can provide valuable insights into their proper usage and the factors that influence their effectiveness. In this article, we will explore the science behind adsorption, the structure of molecular sieves, and the factors that contribute to their efficiency in various applications.

II. The Science of Adsorption

Adsorption is a surface phenomenon where molecules or atoms of a substance (adsorbate) adhere to the surface of a solid or liquid (adsorbent). There are two main types of adsorption: physical and chemical.

Physical Adsorption

Physical adsorption, also known as physisorption, occurs when weak intermolecular forces (such as van der Waals forces) cause the adsorbate to be attracted to the adsorbent’s surface. The process is usually reversible, and the strength of the forces depends on the adsorbate’s molecular size and shape, as well as the adsorbent’s surface properties.

Chemical Adsorption

Chemical adsorption, or chemisorption, involves the formation of chemical bonds between the adsorbate and the adsorbent’s surface. This type of adsorption is generally more selective and has a stronger bond compared to physical adsorption, making it less reversible.

Several factors affect adsorption, such as temperature, pressure, and the concentration of adsorbate in the system. Understanding these factors can help optimize the adsorption process in various applications.

III. Molecular Sieve Structure

Molecular sieves are typically made from zeolites, which are aluminosilicate minerals with a unique porous structure. They have a three-dimensional framework of SiO4 and AlO4 tetrahedra, creating a highly ordered network of interconnected channels and cavities.

Pore Size and Its Significance

The pore size of molecular sieves plays a vital role in their ability to selectively adsorb specific molecules. The pores are uniform in size, allowing for precise control over the separation of molecules based on their size and shape. Molecular sieves are available in various pore sizes, such as 3A, 4A, 5A, and 13X, which correspond to the size of the openings in Angstroms (1 Å = 0.1 nm).

Synthetic vs. Natural Molecular Sieves

Molecular sieves can be either synthetic or natural. Synthetic molecular sieves are manufactured through various processes, allowing for precise control over their structure and properties. Natural zeolites, on the other hand, are formed through geological processes and can be mined from the earth. Synthetic molecular sieves are often preferred for industrial applications due to their consistent properties and performance.

IV. Adsorption Process in Molecular Sieves

The adsorption process in molecular sieves involves several steps, which can be summarized as follows:

- Diffusion: The adsorbate molecules move from the bulk phase to the adsorbent’s surface through diffusion.

- Adsorption: The adsorbate molecules are selectively captured on the adsorbent’s surface based on their size, shape, and affinity for the surface.

- Desorption: The adsorbate molecules are released from the adsorbent’s surface, either by decreasing the pressure or increasing the temperature.

- Diffusion: The released adsorbate molecules move back into the bulk phase.

The pore size of molecular sieves plays a crucial role in selective adsorption. Molecules that are smaller than the pore size can enter the cavities and be adsorbed onto the surface, while larger molecules are excluded. This size-exclusion property allows molecular sieves to efficiently separate and purify gases and liquids based on the size and shape of their constituent molecules.

V. Factors Affecting Molecular Sieve Performance

Several factors influence the performance and efficiency of molecular sieves in adsorption applications:

Adsorbate Concentration

The concentration of adsorbate in the system affects the amount of material that can be adsorbed onto the molecular sieve. Higher concentrations typically result in a greater amount of adsorption.

Temperature

Temperature has a significant impact on the adsorption process. Higher temperatures generally reduce the adsorption capacity of molecular sieves due to the weakening of intermolecular forces. However, in some cases, increasing the temperature can lead to an increase in adsorption capacity, particularly in chemisorption processes.

Pressure

The pressure of the system influences the adsorption process as well. Higher pressures usually result in an increased adsorption capacity, as the adsorbate molecules are forced into closer contact with the adsorbent’s surface.

Regeneration

Molecular sieves can be regenerated by removing the adsorbed material from their surface, allowing them to be reused in subsequent adsorption cycles. The regeneration process typically involves heating the molecular sieve to a specific temperature or applying a vacuum to facilitate desorption. Proper regeneration is essential for maintaining the performance and lifespan of molecular sieves.

VI. Applications of Molecular Sieves

Molecular sieves have a wide range of applications across various industries, some of which include:

Gas Separation and Purification

Molecular sieves are used to separate and purify gases based on the size and shape of their constituent molecules. They are commonly employed in processes such as air separation, natural gas processing, and hydrogen purification.

Drying and Moisture Removal

Molecular sieves can efficiently remove moisture from gases and liquids due to their high adsorption capacity for water molecules. They are used in applications such as drying solvents, refrigerants, and insulating oils.

Catalysis

Some molecular sieves can act as catalysts, facilitating chemical reactions by providing active sites on their surface. Zeolite-based catalysts are used in various industrial processes, including hydrocracking, isomerization, and alkylation.

VII. Frequently Asked Questions for How Molecular Sieves Work

What are molecular sieves?

Molecular sieves are specialized adsorbent materials made from natural or synthetic zeolites. They have a highly porous structure with uniform pore sizes, which allows them to selectively adsorb molecules based on their size and shape.

How do molecular sieves work?

Molecular sieves work through a process called adsorption. They selectively adsorb molecules onto their surface based on the size and shape of the molecules. Smaller molecules can enter the pores and become adsorbed, while larger molecules are excluded, enabling efficient separation and purification of gases and liquids.

What are some common types of molecular sieves?

Some common types of molecular sieves are 3A, 4A, 5A, and 13X. Each type has a specific pore size that allows it to selectively adsorb molecules of a certain size range.

How are molecular sieves regenerated?

Molecular sieves can be regenerated by removing the adsorbed material from their surface, typically by heating the molecular sieve to a specific temperature or applying a vacuum to facilitate desorption. Proper regeneration is essential for maintaining the performance and lifespan of molecular sieves.

In which industries are molecular sieves used?

Molecular sieves are used in a wide range of industries, including petrochemical, pharmaceutical, air separation, natural gas processing, and refrigeration.

What is the role of molecular sieves in gas separation and purification?

Molecular sieves are used in gas separation and purification processes to selectively adsorb and separate molecules based on their size and shape. They provide an efficient and reliable method for purifying gases in various applications.

Can molecular sieves be reused?

Yes, molecular sieves can be reused after regeneration. The regeneration process involves removing the adsorbed material from the molecular sieve’s surface, allowing it to be used in subsequent adsorption cycles.

How do temperature and pressure affect molecular sieve performance?

Temperature and pressure can have significant impacts on molecular sieve performance. Generally, higher temperatures reduce adsorption capacity, while higher pressures increase it. However, the specific effects of temperature and pressure on adsorption depend on the system and the type of molecular sieve used.

What are some applications of molecular sieves in catalysis?

Molecular sieves, particularly zeolite-based catalysts, are used in various industrial processes such as hydrocracking, isomerization, and alkylation. These catalysts facilitate chemical reactions by providing active sites on their surface.

VIII. Conclusion to How Molecular Sieves Work

Molecular sieves play a crucial role in various industrial applications, thanks to their unique adsorption properties and selective nature. Understanding the science behind adsorption, as well as the factors that influence the performance of molecular sieves, can help optimize their usage in gas separation, purification, and drying processes. With their diverse applications and versatility, molecular sieves continue to be an essential tool in many industries.

Types and Applications of Molecular Sieves

Molecular Sieves in the Petrochemical Industry

Your Comprehensive Guide to Molecular Sieves

https://en.wikipedia.org/wiki/Molecular_sieve

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้