Activated Clay vs Bentonite Clay for Moisture Control and Sealing Applications

| Key Takeaways | Description |

|---|---|

| Activated Clay | Excellent for moisture absorption, eco-friendly, and cost-effective. Best for moisture control applications. |

| Bentonite Clay | Ideal for sealing and thickening purposes, used extensively in industrial applications. |

| Moisture Absorption | Activated clay absorbs up to 50% of its weight, while bentonite clay forms a gel-like barrier. |

| Eco-Friendly | Both are natural, but activated clay is more biodegradable. |

Table Of Contents

Introduction

Activated Clay vs Bentonite Clay for moisture control and sealing applications is a common comparison, but what exactly sets these two clays apart? In this post, we’ll break down the key differences and help you understand which one might be the right fit for your needs.

1. What is Activated Clay?

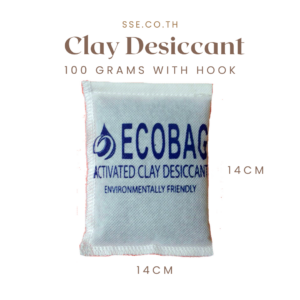

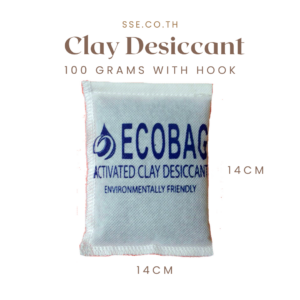

Activated clay is a natural clay desiccant known for its high moisture absorption capabilities. It is often blended with calcium chloride to enhance its moisture-absorbing properties, making it highly effective in a wide range of environments.

| Activated Clay Overview | Details |

| Main Component | Attapulgite clay, treated for increased absorbency |

| Moisture Absorption | Up to 50% of its own weight |

| Primary Use | Moisture control in food packaging, electronics, and pharmaceuticals |

Activated clay is derived from attapulgite clay, which is then treated to increase its absorbency. This treatment makes it a highly reliable option for moisture control solutions across many industries. It is especially favored as an eco-friendly desiccant, capable of absorbing up to 50% of its weight in moisture, making it a preferred choice for industries like food packaging, pharmaceuticals, and electronics.

2. What is Bentonite Clay?

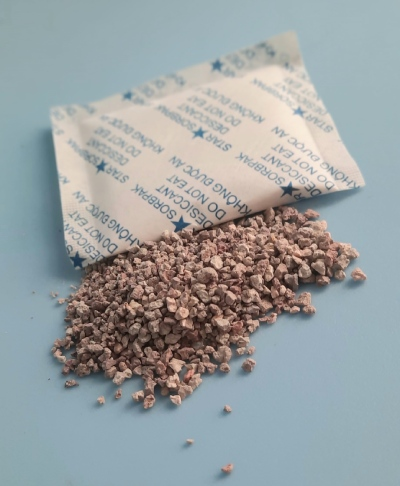

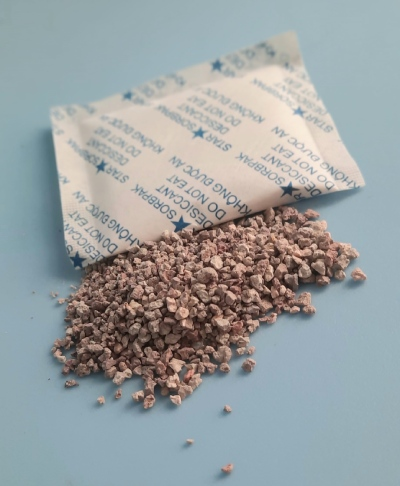

Bentonite clay, often used in industrial settings, is a versatile natural clay that swells when exposed to water, forming a thick gel. This makes it ideal for applications that require sealing or thickening properties.

| Bentonite Clay Overview | Details |

| Main Component | Montmorillonite clay |

| Swelling Ability | Forms a gel when in contact with water |

| Primary Use | Industrial sealing, drilling mud, and construction |

Unlike activated clay, bentonite clay is composed primarily of montmorillonite, which gives it its unique swelling properties. Bentonite clay is frequently used in applications such as drilling mud, foundry sands, and as a binding agent in construction. The clay’s ability to form a gel-like barrier also makes it valuable for preventing leaks and creating impermeable seals in various industrial processes.

3. Key Differences Between Activated Clay vs Bentonite Clay

When it comes to moisture control, both activated clay and bentonite clay have distinct advantages that cater to different needs. Activated clay is primarily focused on absorbing moisture, whereas bentonite clay excels in creating a dense barrier by swelling upon contact with water. Understanding these differences can help determine which material is most suitable for specific applications.

| Activated Clay vs Bentonite Clay | Activated Clay | Bentonite Clay |

| Moisture Absorption | High absorption without shape change | Swells into a gel-like form |

| Best For | Moisture control | Sealing and containment |

| Main Component | Attapulgite | Montmorillonite |

The primary difference lies in their core properties and functionality. Activated clay is highly effective at absorbing moisture without changing its form, which makes it a stable and predictable material for a wide range of moisture absorption needs. This feature makes activated clay ideal for use in environments where maintaining product stability and integrity is crucial, such as food packaging, pharmaceuticals, and electronics.

In contrast, bentonite clay expands significantly when exposed to water. This swelling action results in a compact, dense barrier that is perfect for sealing and containment applications. Bentonite’s ability to swell upon contact with moisture allows it to block leaks, form impermeable barriers, and provide effective containment in a variety of settings, from construction projects to drilling operations. Unlike activated clay, bentonite is not focused on absorbing water but rather on preventing it from moving past a certain point, making it the go-to material for applications like waterproofing foundations, pond sealing, and stabilizing boreholes in drilling.

4. Moisture Absorption Properties

Activated clay excels at moisture absorption, absorbing up to 50% of its weight, while bentonite clay’s moisture control abilities are limited compared to activated clay but effective for creating a barrier.

Activated clay’s ability to absorb moisture is due to its highly porous structure. The activated clay particles have a large surface area, allowing them to draw moisture in and trap it within their structure. This process keeps the environment dry without any structural changes to the desiccant itself. It is a straightforward, highly efficient solution for applications that require constant moisture management, like keeping food products fresh or preventing corrosion of electronic components during shipping.

Activated clay’s ability to absorb significant moisture without structural change makes it ideal for keeping products dry.

| Moisture Absorption Comparison | Activated Clay | Bentonite Clay |

| Absorption Ability | Up to 50% of its weight | Forms a physical barrier rather than absorbing |

| Use Cases | Electronics, food packaging | Industrial sealing, waterproofing |

Activated clay’s exceptional absorption properties make it ideal for situations where keeping an environment dry is crucial. Bentonite clay, on the other hand, controls moisture differently by forming a physical barrier, which helps contain liquids rather than absorb them. This distinction is important for determining the appropriate use for each type of clay.

Bentonite clay, on the other hand, operates on a different principle. When exposed to moisture, bentonite clay swells and transforms into a dense, impermeable layer that serves as a barrier to moisture. This makes it a popular choice for scenarios where stopping water flow is more critical than absorption. Bentonite’s swelling mechanism is highly beneficial in construction, where it is used to waterproof structures, seal landfill liners, or create barriers in ponds and other water containment systems. Unlike activated clay, bentonite’s key feature is its expansion, which provides a physical blockage to water movement rather than absorbing the water itself.

In my experience, activated clay has proven itself consistently superior when it comes to moisture control. The impressive ability of activated clay to absorb up to 50% of its own weight without altering its shape means I can rely on it for critical applications where stability is key. Compared to bentonite clay, which forms a gel, activated clay’s structural integrity makes it a more predictable and manageable option, especially in environments where moisture control is paramount, like in food and pharmaceutical packaging.

5. Common Applications of Activated Clay

Activated clay is used primarily for moisture control in industries like electronics, food packaging, and pharmaceuticals. It provides an eco-friendly and safe way to keep products dry without using harmful chemicals.

Activated clay’s ability to provide moisture absorption without altering its shape ensures that it remains effective throughout its use, regardless of how much moisture it has absorbed. This is an essential characteristic in industries that require stable desiccant properties. For instance, in the pharmaceutical industry, activated clay is used to keep medicine containers dry, ensuring the products stay effective and safe for consumers. In electronics, the non-leaking property of activated clay prevents damage to sensitive components by avoiding both corrosion and chemical reactions.

- Electronics: Prevents humidity-related corrosion of sensitive components.

- Food Packaging: Keeps dry goods fresh by preventing mold and spoilage.

- Pharmaceuticals: Maintains product integrity by ensuring a dry environment.

- Transportation and Logistics: Acts as a container desiccant, preventing condensation and moisture-related damage during transit of sensitive goods.

Activated clay plays an essential role in the electronics industry, particularly in preventing moisture damage to delicate components. Electronics are highly sensitive to humidity, which can cause corrosion, malfunction, or even complete failure of devices. Activated clay, known for its excellent moisture absorption properties, is used in packaging and storage to maintain low humidity levels, ensuring that sensitive components such as circuit boards, sensors, and other precision parts stay dry. By absorbing up to 50% of its own weight in moisture, activated clay helps prevent corrosion and maintains the longevity of electronics.

In addition to storage, activated clay is also valuable during the transportation of electronic goods. Shipping environments often face varying temperature and humidity levels, especially when products are transported overseas or between regions with different climates. Activated clay desiccants are added to shipping containers to ensure that moisture remains controlled during transit. This helps prevent condensation inside the packaging, often referred to as “container rain,” which can cause severe damage to electronics. By stabilizing the environment inside the container, activated clay helps maintain the quality and performance of electronic products from the manufacturer to the end consumer.

Activated clay has an important application in the food packaging industry, where it serves as a natural, eco-friendly desiccant to control moisture levels. In food packaging, moisture can lead to spoilage, mold, and compromised quality of products such as dried fruits, baked goods, and powdered ingredients. Activated clay is particularly effective in maintaining a stable, low-humidity environment inside food packaging, preventing the growth of mold and preserving the freshness of products throughout their shelf life. Its non-toxic and biodegradable properties make activated clay a safe and reliable choice for food manufacturers looking to protect their products naturally, without chemicals that might pose health concerns to consumers.

Activated clay is crucial in the pharmaceutical industry for ensuring product stability and quality. Pharmaceuticals are highly sensitive to moisture, which can lead to reduced efficacy or even spoilage of medicines. Activated clay is used in packaging to keep pharmaceutical products dry, helping to maintain their potency and safety. The high moisture absorption capacity of activated clay provides reliable protection against humidity during storage and transport, making it a preferred solution for protecting everything from tablets to medical devices, ensuring they reach consumers in optimal condition.

Activated clay plays a significant role in transportation and logistics, especially as a container desiccant. During transit, goods are often exposed to varying temperatures and humidity levels, which can lead to moisture accumulation—commonly referred to as “container rain.” This can cause damage to sensitive cargo, including electronics, machinery, and even food products. Activated clay is placed in shipping containers to absorb excess moisture and maintain a dry environment, thereby preventing issues like corrosion, mold, and general degradation of goods. Its non-toxic, eco-friendly nature makes it an ideal solution for ensuring that cargo arrives in optimal condition, regardless of travel distance or climate fluctuations.

6. Common Applications of Bentonite Clay

Bentonite clay has unique uses in industries such as construction, drilling, and even beauty products. Its ability to form a gel makes it perfect for applications like drilling mud, foundry sand, and creating impermeable barriers.

| Industrial Uses of Bentonite Clay | Details |

| Construction | Waterproofing foundations and sealing ponds |

| Drilling | Drilling mud for borehole stability |

| Beauty Products | Ingredient in skincare for impurity removal |

Bentonite clay’s primary strength lies in its versatility as a sealing agent. Due to its swelling properties, it is a natural choice for creating seals in industrial and construction contexts. When mixed with water, bentonite clay forms a dense paste that can effectively block cracks and gaps, preventing any fluid from leaking. This property makes it indispensable in the oil and gas industry for creating drilling mud, which helps stabilize boreholes during drilling operations. It’s also commonly used in creating liners for landfills, ponds, and other water containment systems, offering a reliable, natural solution for preventing water seepage.

Bentonite clay has a significant role in transportation and logistics due to its versatile properties as a natural sealing and moisture barrier agent. It is commonly used in the transportation of bulk cargo, especially where maintaining controlled moisture levels is crucial. Bentonite clay’s ability to swell and create an impermeable layer makes it effective for sealing gaps in containers, preventing the infiltration of moisture that could otherwise damage cargo. Additionally, bentonite is used in protective liners for containers, adding an extra layer of defense for goods that are highly susceptible to moisture, such as agricultural products and certain chemicals.

In the electronics industry, bentonite clay is utilized in packaging materials for transportation to ensure that sensitive components remain protected. Although it doesn’t absorb moisture in the same manner as activated clay, bentonite forms a dense barrier that helps keep moisture out of packaging, which is critical for safeguarding electronic components against potential damage. By preventing ambient humidity from reaching electronics during long-haul transport, bentonite clay ensures that devices, circuit boards, and other delicate parts remain corrosion-free and in optimal working condition upon arrival.

Furthermore, bentonite clay is used in specialized logistics solutions like transportable containment systems. These systems leverage the clay’s ability to form an impermeable layer, which is beneficial for sealing hazardous materials or items that need controlled moisture conditions. Bentonite is ideal for lining containers used in transporting chemicals or other reactive substances, ensuring that no unwanted external moisture or contaminants compromise the cargo. Its sealing capabilities not only enhance the safety of transported goods but also mitigate risks associated with moisture-induced reactions during transit.

A specific instance where bentonite clay proved indispensable was in a construction project involving the waterproofing of a large foundation. Bentonite’s unique ability to swell and form a thick, gel-like barrier made it the ideal material for creating an impermeable seal, which was crucial for preventing water infiltration. Activated clay simply doesn’t have the swelling capacity needed for this kind of application, where the primary goal was to create a durable barrier rather than just absorb moisture. This made bentonite the superior choice for such industrial uses.

7. Benefits of Activated Clay

Activated clay has numerous benefits, including its eco-friendly nature, high moisture absorption capacity, and cost-effectiveness. It is a safe option for applications where non-toxicity is crucial.

Activated clay provides effective moisture control without compromising environmental safety.

| Benefits of Activated Clay | Description |

| Eco-Friendly | Biodegradable and non-toxic |

| High Absorption | Absorbs up to 50% of its weight |

| Safe for Food and Pharma | Ideal for applications requiring non-toxic solutions |

Being a natural clay desiccant, activated clay is biodegradable and poses no risk to the environment. Its use in food packaging, pharmaceuticals, and sensitive electronics highlights its safety and efficacy. Furthermore, because it can absorb moisture effectively without changing form, it provides consistent protection without leakage or deterioration.

8. Benefits of Bentonite Clay

Bentonite clay offers significant benefits in industrial use, such as its ability to create seals, absorb contaminants, and work as a binding agent in foundry sands. Its versatility makes it useful in various industries.

- Waterproofing: Effective in creating barriers for waterproofing foundations and sealing ponds.

- Drilling Stability: Essential in maintaining borehole integrity during drilling.

- Foundry Use: Binds materials to create cohesive molds.

The swelling properties of bentonite clay allow it to form effective barriers, making it ideal for waterproofing and containment. It is also valuable in drilling, where it helps maintain the stability of boreholes. In foundry sands, bentonite’s binding capabilities ensure the cohesiveness of molds, making it a reliable material for manufacturing processes.

9. Eco-Friendly Considerations

Activated clay is biodegradable and non-toxic, making it a better option for those seeking an eco-friendly desiccant. Bentonite clay is also natural but tends to be used in applications where its end product is not as easily biodegradable.

| Eco-Friendly Comparison | Activated Clay | Bentonite Clay |

| Biodegradability | Highly biodegradable | Less relevant in some industrial applications |

| Environmental Impact | Minimal | Moderate, depending on usage |

Activated clay stands out for its role as an eco-friendly desiccant that can be safely disposed of without harming the environment. Bentonite clay, while also a natural material, often ends up in industrial products where its biodegradability may be less relevant. However, both clays contribute to sustainable practices in their respective uses.

10. Choosing the Right Clay for Your Needs

If your primary goal is moisture control, activated clay is the best choice. However, if you need a clay that can act as a sealant or thickening agent, bentonite clay is more suitable.

| Choosing the Right Clay | Activated Clay | Bentonite Clay |

| Best For | Moisture absorption and control | Sealing, thickening, and containment |

| Primary Component | Attapulgite | Montmorillonite |

For industries that prioritize moisture absorption, such as food packaging or electronics, activated clay offers an effective and reliable solution. On the other hand, for construction projects, drilling, or situations requiring impermeable seals, bentonite clay is the better option. Understanding these differences can help you determine which clay fits your specific needs best.

When comparing the performance of activated clay and bentonite clay in moisture-related applications, the differences in their core functions become evident. Activated clay is designed to excel in environments where continuous moisture removal is crucial. This desiccant is excellent for packing environments, such as boxes containing electronics or dry foods, as it keeps them free from moisture-related damage without changing the physical space it occupies. Activated clay’s lack of structural alteration makes it a stable choice, ideal for direct inclusion in product packaging where stability and space consistency are important.

Bentonite clay’s strength, however, lies in situations where it needs to act as a barrier. For example, in applications involving sealing or waterproofing, bentonite’s swelling ability makes it uniquely suited to block water pathways. It creates a dense, gel-like layer that effectively prevents the movement of moisture or other liquids. This feature is particularly useful in infrastructure projects—such as creating a waterproof barrier for building foundations—or in drilling operations where the stability of boreholes must be maintained against underground water pressure.

The biggest challenge I’ve faced in choosing between activated and bentonite clay has been assessing the application’s specific requirements for moisture management versus sealing. In scenarios where maintaining a dry environment was essential—such as in electronics packaging—I opted for activated clay due to its exceptional moisture absorption capacity. Conversely, when containment and sealing were the priorities, as in landfill lining, bentonite clay’s swelling properties provided the best solution. Understanding the unique strengths of each clay helped me tailor the material choice to ensure optimal performance.

Call to Action

If you’re interested in exploring desiccant solutions for your business, check out our full range of Desiccant made from Clay. We provide products that are both effective and environmentally friendly to meet a variety of needs.

Related Posts and Resources

For more detailed insights, you can read our previous post on Activated Clay and its Uses or Attapulgite, Bentonite, and Montmorillonite: Which Clay Suits Your Needs Best? It provides an in-depth look at the various ways activated clay can benefit different industries.

To learn more about our flagship product, Ecobag Natural Clay Desiccant, and its superior capabilities, check out our cornerstone page. If you’re interested in purchasing our product, visit Activated Clay.

For further reading on bentonite clay applications, you may find this external research paper interesting: Swelling of compacted bentonite in organic solvents: Correlation of rate and extent of swelling with solvent properties. Activated clay is ideal for moisture control, while bentonite clay shines in industrial and sealing applications. If you have more questions or need guidance on which type of clay suits your needs, reach out to us. We’re here to help!

Frequently Asked Questions

What are the main differences between Activated Clay vs Bentonite Clay?

The main differences between Activated Clay vs Bentonite Clay are their moisture absorption properties and their applications. Activated clay excels in absorbing moisture without changing shape, making it ideal for desiccant purposes. Bentonite clay, however, swells upon contact with water, forming a gel, making it suitable for sealing and containment applications.

Which clay is better for moisture control: activated clay or bentonite clay?

Activated clay is better for moisture control due to its high moisture absorption capacity, which allows it to absorb up to 50% of its weight. Bentonite clay is more suitable for creating a moisture barrier rather than directly absorbing moisture.

What are the primary applications of activated clay?

Activated clay is primarily used in moisture control for industries like electronics, food packaging, and pharmaceuticals. Its eco-friendly desiccant properties make it a preferred choice for maintaining product quality and extending shelf life.

How is bentonite clay used in industrial settings?

Bentonite clay is widely used in industrial applications such as drilling mud for borehole stabilization, foundry sand for molding, and construction for waterproofing foundations. Its ability to swell and create a thick barrier makes it ideal for these purposes.

Can activated clay and bentonite clay be used interchangeably?

No, activated clay and bentonite clay cannot be used interchangeably. Activated clay is best for moisture absorption, whereas bentonite clay is better for sealing, containment, and applications requiring a gel-like consistency.

Is activated clay an eco-friendly desiccant?

Yes, activated clay is an eco-friendly desiccant. It is biodegradable, non-toxic, and can be safely disposed of, making it an excellent choice for those who are environmentally conscious.

Why is calcium chloride often added to activated clay?

Calcium chloride is added to activated clay to enhance its moisture absorption properties. The combination makes the desiccant more effective, especially in high-humidity environments, boosting the overall moisture control capacity.

Which clay is more cost-effective for moisture control applications?

Activated clay is generally more cost-effective for moisture control applications. Its natural abundance, high absorption capacity, and reusability make it a budget-friendly choice compared to other desiccants.

What industries benefit the most from using bentonite clay?

Industries such as construction, drilling, and foundry benefit the most from using bentonite clay. Its ability to create impermeable seals, stabilize boreholes, and bind materials makes it indispensable for these applications.

How do activated clay and bentonite clay compare in terms of biodegradability?

Both activated clay and bentonite clay are natural and biodegradable. However, activated clay is more easily biodegradable and environmentally friendly, whereas bentonite clay is often used in applications where its biodegradability is less of a concern, such as in construction or industrial containment.

Conclusion

Ultimately, the choice between activated clay and bentonite clay depends heavily on the intended application. For those looking to manage moisture effectively by absorption, activated clay offers the best solution due to its high absorption capacity and consistent performance. It’s the perfect choice for use in packaging, where moisture control is key to preserving the quality and integrity of the product.

In contrast, if the goal is to create a seal or a barrier against water, bentonite clay is the superior choice. Its ability to swell and form a compact layer makes it ideal for construction projects, waterproofing, and applications where stopping moisture flow is more important than absorbing it. The properties of each type of clay are uniquely suited to different challenges, making it important to consider the specific needs of a project before choosing between the two.

Understanding the fundamental differences between activated clay and bentonite clay allows for a more informed decision when choosing the best material for your specific application. Whether it is the moisture absorption strength of activated clay or the sealing capabilities of bentonite, each has distinct properties that make it invaluable in different industries and use cases.

Understanding the differences between Activated Clay vs Bentonite Clay for moisture control and sealing applications can help you make an informed decision based on your specific needs. Activated clay is ideal for moisture control, while bentonite clay shines in industrial and sealing applications. If you have more questions or need guidance on which type of clay suits your needs, reach out to us. We’re here to help!

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้