Preventing Cargo Sweat and Container Rain

Table of Contents

Introduction

In the world of cargo transportation, maintaining the quality of goods is paramount, and one of the challenges that shippers often face is a phenomenon known as “cargo sweat.” This term refers to the condensation that forms on the surface of the cargo when it’s being transported in a shipping container. It’s a common issue, particularly in certain climatic conditions, and it can cause significant damage to the goods, leading to financial losses and customer dissatisfaction.

Cargo sweat is essentially a form of moisture damage. It occurs when the temperature inside the shipping container falls below the dew point of the air. The dew point is the temperature at which the air can no longer hold all its water vapor, and some of it condenses into liquid water. When this happens inside a shipping container, the water droplets form on the coolest available surface, which is often the cargo itself.

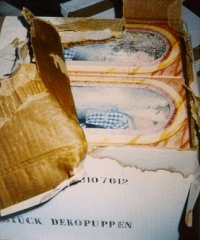

The problem with cargo sweat is that it can lead to a variety of moisture-related issues. For instance, it can cause cardboard packaging to become soggy and weak, potentially leading to the collapse of stacked goods. It can also lead to the growth of mold and mildew, which can damage goods and potentially pose health risks. Metal items can rust, and food products can spoil. In short, cargo sweat can be a major problem for shippers.

The risk of cargo sweat is particularly high when shipping goods across large climatic zones. For example, if goods are loaded into a container in a hot, humid climate and then transported to a cooler climate, the conditions inside the container can quickly reach the dew point, leading to the formation of cargo sweat. Similarly, if goods are loaded in a cold climate and then transported to a warmer climate, the warm air entering the container can cause condensation on the cool cargo.

Understanding cargo sweat is the first step towards preventing it. It’s important to realize that it’s not just the temperature inside the container that matters, but also the relative humidity and the temperature of the cargo itself. These factors are interrelated and can all contribute to the formation of cargo sweat.

Understanding Cargo Sweat

To effectively prevent cargo sweat, it’s important to first understand what it is and why it occurs. As we’ve mentioned, cargo sweat is essentially condensation that forms on the surface of the cargo during transportation. It’s a result of the interplay between temperature, humidity, and dew point within the shipping container. But what does this mean, and how does it lead to cargo sweat? Let’s delve deeper into these concepts.

Temperature is a measure of how hot or cold something is. In the context of a shipping container, we’re interested in two temperatures: the temperature of the air inside the container, and the temperature of the cargo itself. These temperatures can differ, particularly when the cargo has been stored in a different environment prior to loading, or when the cargo is refrigerated.

Humidity is a measure of the amount of water vapor in the air. The more water vapor, the higher the humidity. When the air is fully saturated with water vapor, we say that the humidity is 100%. However, the amount of water vapor that the air can hold depends on the temperature: warmer air can hold more water vapor than cooler air.

This brings us to the concept of the dew point. The dew point is the temperature at which the air becomes fully saturated with water vapor. If the temperature falls below the dew point, the air can no longer hold all its water vapor, and some of it condenses into liquid water. This is why dew forms on grass on cool mornings: the temperature of the grass has fallen below the dew point of the air.

Now, let’s consider what happens inside a shipping container. When the cargo is loaded, the air inside the container will generally have the same temperature and humidity as the air outside. However, as the container is sealed and transported, the conditions inside can change. If the container is transported to a cooler climate, the temperature inside the container will fall. If it falls below the dew point, cargo sweat can form.

Similarly, if the container is transported to a warmer climate, the temperature inside the container will rise. If the cargo is cooler than the air, the warm air can condense on the cargo, causing cargo sweat. This is known as “container rain.”

The risk of cargo sweat is also influenced by the type of cargo. Some goods, such as metal items and certain types of food, are particularly susceptible to moisture damage. Other goods, such as textiles and paper products, can absorb moisture from the air, reducing the risk of condensation.

The Science Behind Cargo Sweat

Cargo sweat is a result of specific atmospheric and environmental conditions inside the shipping container. To fully grasp the science behind cargo sweat, we need to delve into the principles of physics and meteorology that govern the behavior of air and moisture. This understanding is crucial to devising effective strategies for preventing cargo sweat and ensuring the safe transportation of goods.

Let’s start with the basics. Air, like any gas, is composed of molecules that are in constant motion. The speed of these molecules is determined by the temperature: the higher the temperature, the faster the molecules move. When the temperature drops, the molecules slow down. This change in molecular motion affects the air’s capacity to hold water vapor.

At higher temperatures, air can hold more water vapor. This is because the faster-moving molecules create more space between them, allowing more water vapor to be accommodated. Conversely, when the temperature drops, the air’s capacity to hold water vapor decreases. If the air is saturated with water vapor, a decrease in temperature can cause the excess water vapor to condense into liquid water. This is the process that leads to the formation of dew in nature, and cargo sweat in a shipping container.

The point at which condensation occurs is called the dew point. If the temperature inside the shipping container falls below the dew point, cargo sweat can form. This is most likely to happen when the container is transported from a warm climate to a cooler one. The air inside the container, initially warm and humid, cools down along with the container. If the temperature falls below the dew point, the excess water vapor condenses on the coolest available surface – which is often the cargo.

Another scenario that can lead to cargo sweat is known as “container rain.” This occurs when the cargo is cooler than the air inside the container. When warm, humid air comes into contact with the cool surface of the cargo, it cools down and its capacity to hold water vapor decreases. The excess water vapor condenses on the cargo, leading to cargo sweat.

The risk of cargo sweat is further influenced by the hygroscopic properties of the cargo – that is, its ability to absorb moisture from the air. Some materials, such as textiles and paper, are highly hygroscopic and can absorb a significant amount of moisture before becoming damp. Other materials, such as metal and plastic, are non-hygroscopic and provide a surface for condensation as soon as the dew point is reached.

U. Scharnow

Impact of Cargo Sweat on Different Types of Goods

The effects of cargo sweat can vary significantly depending on the type of goods being transported. From food items to electronics, textiles to machinery, each type of cargo has its unique vulnerabilities when exposed to moisture. Understanding these impacts is crucial for devising effective strategies to prevent cargo sweat and ensure the safe and efficient transportation of goods.

Let’s start with food items. These are often highly susceptible to moisture damage. For instance, grains, spices, and other dry food items can clump together when exposed to moisture, making them unappealing and potentially unsellable. Moreover, excess moisture can promote the growth of mold and bacteria, posing serious health risks. Canned foods, while more resistant to moisture, can still suffer from rusting and label damage due to cargo sweat.

Electronics and machinery are another category of goods that can be severely affected by cargo sweat. Moisture can cause corrosion of metal parts, potentially leading to mechanical failures. In electronic devices, moisture can cause short circuits and other electrical issues that can render the device unusable. Additionally, packaging materials for electronics and machinery, such as cardboard boxes and paper manuals, can become damp and weak, compromising their protective function.

Textiles and clothing items are also vulnerable to cargo sweat. Moisture can lead to discoloration, mold growth, and unpleasant odors. Leather goods can warp and crack when exposed to moisture. Moreover, damp conditions can cause dye in colored textiles to bleed, ruining the appearance of the items.

Pharmaceuticals and healthcare products, too, can suffer from exposure to moisture. Many pharmaceuticals are sensitive to humidity and can lose their efficacy if exposed to damp conditions. Similarly, medical devices can suffer from corrosion and other moisture-related damage.

Even goods that are not directly damaged by moisture can be affected by cargo sweat. For instance, metal goods that are not prone to rusting can still be affected if their packaging becomes damp and weak. Similarly, plastic items can become slippery and difficult to handle if their surfaces are wet.

In addition to the direct damage to goods, cargo sweat can also lead to secondary issues. For instance, damp conditions inside the container can promote the growth of mold and mildew, which can cause unpleasant odors and potential health risks. Moreover, the process of cleaning and repairing moisture-damaged goods can be time-consuming and costly.

Preventing Cargo Sweat: The Role of Desiccants

One of the most effective ways to prevent cargo sweat is through the use of desiccants, such as InterDry Power Desiccant. These powerful tools work by absorbing excess moisture in the air, thereby reducing the relative humidity inside the shipping container and preventing the formation of cargo sweat. In this section, we’ll delve into the science behind desiccants, how they work, and why they are a crucial part of any strategy to prevent cargo sweat.

Desiccants are substances that have a high affinity for water. They attract and hold water molecules from the surrounding environment, effectively ‘drinking up’ excess moisture in the air. This ability to absorb water is due to the chemical structure of desiccants, which often contain compounds that form weak bonds with water molecules. When these bonds form, the water molecules become trapped within the desiccant, reducing the amount of free water vapor in the air.

InterDry Power Desiccant is a prime example of a high-performance desiccant. It is designed to absorb more than 300% of its weight in moisture, making it an incredibly efficient tool for controlling humidity inside shipping containers. Moreover, InterDry Power Desiccant is packed in special Tyvek and Spunbond packing that allows only one-way absorption, ensuring the desiccant is completely leak-proof and efficient.

But why is controlling humidity so important? As we’ve learned, cargo sweat occurs when warm, humid air comes into contact with cooler surfaces, causing the water vapor in the air to condense into liquid water. By reducing the amount of water vapor in the air, desiccants can prevent this condensation process from occurring, thereby preventing cargo sweat.

Using desiccants is relatively straightforward. They are typically placed inside the shipping container before the cargo is loaded. The desiccants then start absorbing moisture from the air as soon as the container is sealed. Over time, they effectively lower the relative humidity inside the container, preventing the formation of cargo sweat.

However, it’s important to note that not all desiccants are created equal. The effectiveness of a desiccant depends on several factors, including its absorption capacity, the amount of desiccant used, and the specific conditions inside the shipping container. That’s why it’s crucial to choose a high-quality desiccant like InterDry Power Desiccant and to calculate the correct quantity needed for your specific situation.

Photo: Scheen

Other Strategies to Prevent Cargo Sweat

While desiccants play a crucial role, there are other strategies that can be employed to prevent cargo sweat. These strategies are particularly important when transporting goods in standard containers over sea routes where there is a significant rise in air temperature.

Firstly, when packing the container, it’s crucial to ensure good air circulation between the container surfaces and the cargo surfaces. This allows for rapid and thorough heating of the cargo, which can help to prevent the formation of cargo sweat. This is especially important for goods that release larger amounts of water vapor.

Secondly, the selection of an optimum stowage space can also play a significant role in preventing cargo sweat. For containers on deck, it’s advisable to stow them away from radiation in the inner layers of the deck cargo to achieve rapid heating of the container and its contents. For containers shipped below deck, intensive ventilation is recommended to heat the containers and their contents. Any sweat that arises on the outside of the container is harmless, provided that the container arrives dry on the outside at the port of destination.

Containers that are at particular risk, such as those destined for the first port of destination or those that will be immediately unpacked upon arrival, should be positioned in the immediate vicinity of the fan outlets or in places near heated double bottom cells or bulkheads. This can help to ensure that the containers and their contents are adequately heated, reducing the risk of cargo sweat.

Lastly, if the containers are to be inspected in port, for example by customs officers, it’s important to open the container only briefly or under a plastic shroud. This is because in sub-tropical ports, the surface of the cargo can become moist very quickly when exposed to the air, leading not to cargo sweat but to potential claims.

Case Study: Successful Prevention of Cargo Sweat

Let’s look at a real-world example of how proper measures can successfully prevent cargo sweat and protect the quality of goods. This case study involves a shipping route from Rostock to West Africa, with a ship making an outward and return voyage in the month of November.

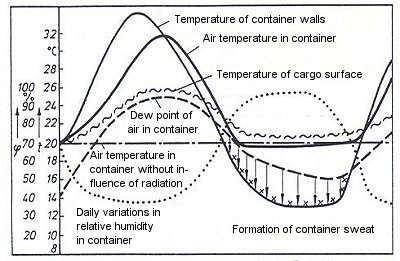

The external air temperature on the outward voyage rises from 4°C in Rostock to 26°C in Conakry. Meanwhile, the temperature of the cargo surface increases from 2°C to 16°C. Despite this temperature increase, cargo sweat is expected on the outward voyage because the surface temperature of the cargo is lower than the dew point of the external air.

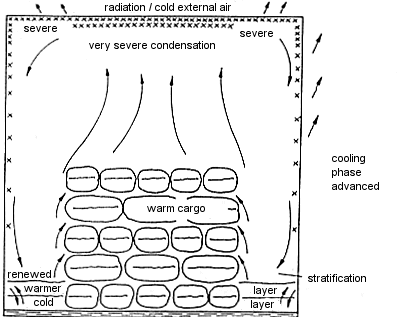

On the return voyage, the external air temperature drops relatively rapidly due to the distance traveled and the weather conditions. The cargo in the container often cannot adapt quickly enough to this change in temperature. As a result, the container is cooled in the external air to below the dew point temperature of the air, leading to the formation of container sweat, especially on the container ceiling. Once enough sweat has formed, it drips down onto the cargo.

However, this situation can be effectively managed with the right preventive measures. By using desiccants like InterDry Power Desiccant and ensuring proper ventilation, the formation of cargo sweat can be minimized. This case study highlights the importance of understanding the conditions that lead to cargo sweat and taking proactive steps to prevent it.

Conclusion: The Importance of Preventing Cargo Sweat

The prevention of cargo sweat is not just about maintaining the quality of goods, but also about ensuring the efficiency and profitability of your shipping operations. Cargo sweat can lead to significant losses due to damage to goods, leading to unsatisfied customers and potential financial losses. Moreover, it can also result in additional costs related to the cleaning and maintenance of shipping containers.

By understanding the science behind cargo sweat and implementing effective preventive measures, you can protect your cargo, maintain the integrity of your shipping containers, and ensure the smooth operation of your shipping processes. Remember, prevention is always better than cure, especially when it comes to protecting your valuable cargo from the damaging effects of cargo sweat.

Call to Action

Now that you understand the importance of preventing cargo sweat, it’s time to take action. The safety and integrity of your cargo should be a top priority, and understanding how to prevent cargo sweat is a crucial part of that. Whether you’re shipping electronics, food products, or any other goods susceptible to moisture damage, taking steps to prevent cargo sweat can save you from potential losses and ensure your goods arrive at their destination in the best possible condition.

One of the most effective ways to prevent cargo sweat is by using desiccants like InterDry Power Desiccant. These products are designed to absorb excess moisture in the air, preventing the formation of cargo sweat. By incorporating desiccants into your shipping practices, you can significantly reduce the risk of moisture damage to your goods.

But using desiccants is just one part of the solution. It’s also important to consider other factors such as the temperature and humidity conditions of your shipping route, the type of cargo you’re shipping, and the packaging materials you’re using. All of these factors can influence the likelihood of cargo sweat occurring.

Don’t wait until you’ve experienced a loss to take action. Start implementing these preventative measures today to protect your cargo from the damaging effects of cargo sweat. Whether you’re new to shipping or an experienced professional, it’s never too late to improve your practices and ensure the safety of your goods.

Remember, the cost of preventing cargo sweat is much less than the cost of dealing with damaged goods. Invest in quality desiccants, monitor your shipping conditions, and take the necessary steps to prevent cargo sweat. Your cargo, and your bottom line, will thank you.

Ready to get started? Contact us to learn more about our desiccant products and how they can help you prevent cargo sweat. Our team is ready to assist you with any questions you may have and guide you towards the best solutions for your shipping needs. Or call: 0858124188

FAQs

Here are some frequently asked questions about cargo sweat and its prevention.

What is Cargo Sweat?

Cargo sweat is like when you get out of a cold swimming pool on a hot day, and water droplets form on your skin. But in this case, it’s happening inside a shipping container. When the air inside the container is cooler than the air outside, and there’s a lot of moisture in the air, water droplets can form on the cargo. This is called cargo sweat.

Why does it happen?

Cargo sweat happens because of differences in temperature and humidity. When warm, moist air comes into contact with a cooler surface, it can’t hold onto as much moisture. So, the extra moisture turns into water droplets. This is the same thing that happens when a cold glass of lemonade “sweats” on a hot day.

Why is it a problem?

Cargo sweat can be a big problem because it can damage the goods being shipped. If water droplets form on your cargo, they can cause things like rust, mold, or other types of damage. This is especially a problem for things like electronics, metal goods, or food products.

How can it be prevented?

There are a few ways to prevent cargo sweat. One of the best ways is to use something called a desiccant. Desiccants are materials that absorb moisture from the air. By using desiccants, you can reduce the amount of moisture in the air inside the shipping container, which can help prevent cargo sweat. Another way to prevent cargo sweat is to make sure that the cargo and the container are at the same temperature when they are loaded. This can help reduce the amount of warm, moist air that comes into contact with cooler surfaces.

What are some examples?

Let’s say you’re shipping a container of electronics from a cold country to a hot, humid country. When the container arrives in the hot country, the warm, moist air could cause cargo sweat and damage the electronics. But if you use desiccants and make sure the container and the electronics are at the same temperature when they are loaded, you can help prevent this from happening.

What’s the difference between cargo sweat and container rain?

“Cargo sweat” and “container rain” are two terms used in the shipping industry to describe similar phenomena related to condensation in shipping containers, but they occur under different conditions.

1. Cargo Sweat: This term refers to the condensation that forms on the cargo itself. It typically occurs when warm, moist air inside the container comes into contact with cooler cargo. This is most common when a container is loaded in a warm climate and then transported to a cooler one. The warm air inside the container cools down when it comes into contact with the cooler cargo, and its capacity to hold moisture decreases. This leads to condensation forming directly on the cargo, hence the term “cargo sweat.”

2. Container Rain: This term refers to the condensation that forms on the roof and walls of the shipping container. It typically occurs when the air inside the container is warm and humid, and the container itself is cooler. This is most common when a container is loaded in a warm, humid climate and then cools down, either due to nighttime temperatures or because it’s transported to a cooler climate. The warm, moist air inside the container comes into contact with the cooler walls and roof of the container, and condensation forms. This condensation can then drip down onto the cargo, hence the term “container rain.”

In both cases, the condensation can potentially damage the cargo, especially if the cargo is sensitive to moisture. Therefore, it’s important to take measures to prevent both cargo sweat and container rain when shipping goods, especially in varying climates. This can include using desiccants to absorb excess moisture, ventilating the container properly, and considering the use of insulation or temperature-controlled containers for particularly sensitive cargo.

What is the 3 degree rule?

The 3 degree rule is a guideline in the shipping industry that suggests that cargo sweat can be prevented if the cargo’s temperature is at least 3 degrees lower than the dew point of the air at the time of loading.

What is container sweat?

Container sweat is similar to cargo sweat. It refers to the condensation of moisture on the inside surfaces of the shipping container.

How do you prevent ship sweat and cargo sweat?

Ship sweat and cargo sweat can be prevented by maintaining a stable temperature inside the shipping container, providing adequate ventilation, and using desiccants to control moisture levels.

What precautions should be taken to protect steel cargo from condensation?

To protect steel cargo from condensation, it’s important to maintain a stable temperature inside the container, provide adequate ventilation, and use desiccants to control moisture levels. It’s also beneficial to use rust inhibitors or protective coatings on the steel.

What is cargo ventilation?

Cargo ventilation refers to the process of allowing air to circulate inside the shipping container. This helps to regulate temperature and humidity levels, preventing the formation of sweat.

What is the common cause of cargo damage?

The most common cause of cargo damage is exposure to moisture, which can lead to mold, corrosion, and other forms of damage. Other causes include improper handling, inadequate packaging, and extreme temperature fluctuations.

What is cargo damage?

Cargo damage refers to any harm that occurs to goods during transit. This can include physical damage, such as dents or breaks, as well as damage caused by moisture, temperature fluctuations, or contamination.

How do you minimize cargo damage?

Cargo damage can be minimized through proper packaging, the use of desiccants to control moisture, maintaining a stable temperature during transit, and handling the cargo with care.

Do cargo containers sweat?

Yes, cargo containers can sweat when the temperature and humidity conditions inside the container lead to the condensation of moisture. This is often referred to as container sweat.

What is cargo conditioning?

Cargo conditioning refers to the process of maintaining optimal temperature and humidity conditions for the cargo during transit. This can involve the use of climate-controlled containers, desiccants, and other strategies to prevent sweat formation and other forms of cargo damage.

Why is cargo ventilation important?

Cargo ventilation is important because it helps to regulate temperature and humidity levels inside the shipping container. This can prevent the formation of sweat and help to maintain the quality of the cargo.

Does 3 degrees make a difference?

Yes, a difference of 3 degrees can be significant in the shipping industry. According to the 3 degree rule, maintaining the cargo’s temperature at least 3 degrees below the dew point of the air at the time of loading can help to prevent cargo sweat.

What is dew point?

The “dew point” is the temperature at which air becomes saturated with water vapor. When the temperature drops to the dew point, the air is unable to hold all of the water vapor it contains, and some of it condenses into liquid water, forming dew. In the context of shipping, if the temperature inside a container drops below the dew point, condensation can form on the cargo, leading to what is known as “cargo sweat”.

Read more

How to Calculate the Quantity of Container Desiccant

Hygroscopic Goods and Their Role in Sweat Formation in Shipping Containers