The Impact of Relative Humidity on Cargo: A Case Study of Thailand to the US Transportation

Explore the critical role of Relative Humidity in international shipping. From the humid climate of Thailand to the dry environment of the US, understand how Relative Humidity affects cargo quality, packaging, and transportation. Learn about innovative solutions and mitigation strategies to navigate the complex interplay between Relative Humidity and global commerce.

Table of Contents

Introduction

| Aspect | Description |

|---|---|

| Understanding RH | Definition and importance of relative humidity (RH) in shipping. |

| Global Context | Comparison of RH in Thailand (80%) and the US (30%). |

| Importance in Shipping | How RH affects various types of cargo, including food, metals, and electronics. |

- With Thailand’s relative humidity averaging around 80% and the US’s around 30%, the effects on cargo can be quite pronounced.

- Importance in Shipping: The humidity levels can affect various types of cargo, from food products to electronics. Understanding and managing these effects is vital for successful shipping.

- Journey Overview: This article explores the various phases of the voyage, focusing on the effects of temperature and humidity changes on the cargo, from loading in Thailand to arrival in the US.

In the world of shipping, understanding the dance between temperature, humidity, and cargo isn’t just science; it’s an art that requires precision, care, and innovation.

Understanding Relative Humidity

Relative humidity (RH) is more than just a weather term; it’s a crucial factor in international shipping that can significantly impact the quality and safety of goods in transit. Here’s a deeper look into what relative humidity is and why it matters:

Definition and Measurement

- What Is Relative Humidity?: RH is the ratio of the current humidity to the maximum humidity that the air can hold at a given temperature. It’s expressed as a percentage, with 100% RH meaning the air is fully saturated with water vapor.

- Measurement: Instruments like hygrometers and psychrometers are used to measure RH. These tools are essential in shipping to monitor and control the humidity levels within containers.

High vs. Low Relative Humidity

- High Relative Humidity (Above 60%):

- Moist Environment: High RH indicates a moist environment, where the air holds a large amount of water vapor.

- Effects on Cargo: It can lead to moisture absorption, corrosion, mold growth, and other issues that can damage goods like food, textiles, metals, and electronics.

- Example: In tropical regions like Thailand, high RH is common, and special care must be taken to protect cargo.

- Low Relative Humidity (Below 40%):

- Dry Environment: Low RH signifies dry conditions, where the air holds less water vapor.

- Effects on Cargo: It can cause drying, brittleness, static electricity, and shrinkage in materials like wood, leather, and certain plastics.

- Example: In arid regions or during winter in places like the US, low RH can pose challenges to shipping.

Importance in Different Phases of Shipping

- Loading Phase: Proper understanding and control of RH are vital when loading cargo, especially in humid regions. Special packaging and climate-controlled containers may be required.

- During the Voyage: Fluctuations in RH during the voyage can lead to condensation or drying issues. Regular monitoring and adjustments are essential to maintain optimal conditions.

- Unloading Phase: Sudden exposure to different RH levels when unloading can cause shocks to the cargo. Gradual acclimatization and proper handling are key.

Mitigation Strategies

- Climate-Controlled Containers: These containers allow for precise control of temperature and humidity, ensuring the cargo’s safety.

- Regular Monitoring: Using sensors and regular inspections to monitor RH levels and make necessary adjustments.

- Understanding the Cargo’s Needs: Different goods have different sensitivity levels to RH. Knowing the specific requirements of the cargo helps in choosing the right packaging and handling methods.

Loading Cargo in High Temperature, High Humidity Environment (Thailand)

| Aspect | Description |

|---|---|

| Hot Air & Water | High temperature in Thailand allows air to hold more water. |

| Moisture Absorption | Risks to textiles and food due to moisture absorption. |

| Corrosion Risks | Metals may corrode faster due to moisture. |

| Packaging Challenges | Need for special packaging to protect against moisture and condensation. |

| Potential Health Risks | Risks to pharmaceuticals and medical supplies. |

| Mitigation Strategies | Use of moisture barriers, sealed containers, and climate control. |

Thailand’s tropical climate, characterized by high temperatures and humidity, presents unique challenges for shipping. The hot air’s ability to hold more water results in a moist environment that can affect various types of cargo. Here’s a detailed look at the challenges and mitigation strategies:

Hot Air Holds More Water

- Science Behind It: Warm air can hold more water vapor than cold air. In Thailand, the high temperatures often lead to humidity levels around 80% or more.

- Impact on Cargo: This high humidity can create a moist environment inside shipping containers, affecting the goods inside.

Moisture Absorption

- Goods Affected: Particularly vulnerable are food products, textiles, and paper goods.

- Effect on Cargo: These goods may absorb the excess moisture in the air, leading to spoilage, mold growth, or loss of structural integrity.

- Real-life Example: Thai rice exports may face challenges like mold or discoloration if not properly protected.

- Mitigation: Using moisture-absorbing materials, proper sealing, and moisture barriers can help prevent these issues.

Corrosion Risks

- Goods Affected: Metals, machinery, and automobile parts.

- Effect on Cargo: The moisture in the air can lead to faster corrosion and rusting.

- Real-life Example: Machinery parts may require special coatings or treatments to prevent rust.

- Mitigation: Utilizing anti-corrosion materials, coatings, and controlled environments can minimize these risks.

Packaging Challenges

- Need for Special Packaging: The high humidity requires specialized packaging to protect against moisture and condensation.

- Materials Used: This may include vacuum-sealed packaging, moisture barriers, and desiccants.

- Challenges: Finding the right balance between protection and cost-effectiveness can be a complex task.

- Mitigation: Understanding the specific needs of the cargo and using appropriate packaging materials and techniques.

Potential Health Risks

- Goods Affected: Pharmaceuticals, medical supplies, and other health-related products.

- Effect on Cargo: High humidity can lead to the degradation of these products, affecting their efficacy and safety.

- Real-life Example: Certain medications may lose their potency if exposed to high humidity.

- Mitigation: Specialized packaging, storage conditions, and climate-controlled containers can ensure product integrity.

Mitigation Strategies

- Moisture Barriers: Using materials that prevent moisture penetration, like plastic wraps or coatings.

- Sealed Containers: Ensuring that containers are properly sealed to prevent humidity from entering.

- Climate-Controlled Environments: Utilizing containers with controlled temperature and humidity to maintain optimal conditions.

- Regular Monitoring: Implementing sensors and regular checks to ensure that conditions remain within acceptable levels.

Loading cargo in Thailand’s high temperature, high humidity environment is a complex task that requires careful planning, understanding of the goods, and the right strategies. From protecting against moisture absorption to preventing corrosion and ensuring the safety of health-related products, each step requires attention to detail and expertise.

By employing moisture barriers, sealed containers, climate-controlled environments, and regular monitoring, shippers can navigate these challenges successfully. It’s a testament to human ingenuity and adaptability, turning a challenging climate into a manageable aspect of global commerce.

During the Voyage (Cooling Down)

| Aspect | Description |

|---|---|

| Temperature Drop | Temperature may drop during the voyage, affecting cargo. |

| Condensation Formation | Cooling air leads to condensation on container walls and goods. |

| Risk to Electronics | Condensation can affect electronic goods. |

| Wood & Organic Materials | Potential contraction or deformation due to temperature changes. |

| Mitigation Strategies | Regular monitoring, controlled temperature, and humidity within containers. |

The journey of cargo is a journey through climates. From the humid ports of Thailand to the dry lands of the US, every shipment tells a story of adaptation, resilience, and human ingenuity.

As a shipping container makes its journey across the ocean, it may encounter cooler regions, leading to a drop in temperature inside the container. This cooling down phase presents unique challenges, especially when the cargo was loaded in a high humidity environment. Here’s a detailed exploration of these challenges and how to mitigate them:

Temperature Drop

- Why It Happens: The voyage may include crossing cooler oceanic regions or experiencing seasonal changes, leading to a drop in external temperature.

- Impact on Cargo: The temperature inside the container may drop correspondingly, affecting the goods inside, especially if they were loaded in a high humidity environment.

Condensation Formation

- Science Behind It: Cooler air can’t hold as much moisture as warm air. If the air inside the container cools down, it may lead to condensation as the excess moisture is released.

- Where It Forms: Condensation may form on the container walls, ceiling, and even on the goods themselves.

- Potential Damage: This can lead to water damage, spoilage, or other issues, depending on the nature of the cargo.

- Mitigation: Using insulation, moisture barriers, and proper ventilation can help prevent or minimize condensation.

Risk to Electronics

- Goods Affected: Electronic devices, components, and machinery.

- Effect on Cargo: Condensation can cause short circuits, malfunctions, or permanent damage to electronic goods.

- Real-life Example: A shipment of smartphones may suffer functionality issues if exposed to condensation.

- Mitigation: Utilizing anti-condensation materials, sealed packaging, and climate-controlled containers can protect electronics.

Wood and Organic Materials

- Goods Affected: Wooden furniture, artworks, organic fabrics, and other natural materials.

- Effect on Cargo: These materials may contract, warp, or deform due to temperature changes and condensation.

- Real-life Example: A wooden sculpture may crack or warp if not properly protected during the voyage.

- Mitigation: Using specialized packaging, controlled environments, and understanding the specific needs of the materials can prevent these issues.

Mitigation Strategies

- Regular Monitoring: Implementing sensors and regular checks to monitor temperature and humidity levels inside the container.

- Controlled Temperature and Humidity: Utilizing containers with climate control features to maintain optimal conditions.

- Proper Packaging: Understanding the specific needs of the cargo and using appropriate packaging materials and techniques.

- Early Detection: Regular inspections and monitoring can lead to early detection of potential issues, allowing for timely intervention.

The cooling down phase during a voyage is a critical period that requires careful planning and attention. From understanding the science of condensation to protecting sensitive goods like electronics and wood, each step must be handled with expertise.

By employing regular monitoring, controlled temperature and humidity, proper packaging, and early detection, shippers can ensure that the cargo reaches its destination in the best possible condition. It’s a delicate balance, where technology, knowledge, and vigilance come together to turn potential challenges into a smoothly managed process.

Arrival in a Cold Environment with Low Humidity (US)

| Aspect | Description |

|---|---|

| Sudden Exposure | Sudden change in conditions inside the container upon arrival. |

| Static Electricity Risks | Low humidity can increase static electricity, affecting electronics. |

| Drying Effects | Goods may dry out, leading to brittleness or quality degradation. |

| Potential Shrinkage | Leather and certain plastics may shrink or deform. |

| Mitigation Strategies | Gradual acclimatization, anti-static packaging, proper handling. |

Weather is not just a casual conversation starter; it’s the unseen force that shapes our world, our commerce, and our daily lives. In shipping, a degree of humidity can be the difference between success and failure.

The arrival of cargo in a cold, low-humidity environment like the US presents a new set of challenges. The sudden exposure to different climatic conditions can have various effects on the goods inside the container. Here’s a detailed exploration of these challenges and how to mitigate them:

Sudden Exposure

- What Happens: Opening the container doors in a cold, low-humidity environment can cause a sudden change in temperature and humidity inside the container.

- Impact on Cargo: This sudden change can shock the goods inside, leading to potential damage or quality degradation.

- Mitigation: Gradual acclimatization, careful handling, and planning the unloading process can minimize these risks.

Static Electricity Risks

- Why It Happens: Low humidity often leads to an increase in static electricity, as the dry air allows for the buildup of static charges.

- Goods Affected: Electronic components, machinery, and other sensitive items.

- Effect on Cargo: Static electricity can cause malfunctions, data loss, or permanent damage to electronic goods.

- Real-life Example: Computer parts may require special handling and packaging to prevent static damage.

- Mitigation: Utilizing anti-static packaging, grounding, and other measures can protect against static electricity.

Drying Effects

- Goods Affected: Wood, organic materials, textiles, and other moisture-sensitive items.

- Effect on Cargo: The low humidity can cause these goods to dry out, leading to brittleness, cracking, or other quality degradation.

- Real-life Example: Wooden furniture may crack or lose its finish if exposed to low humidity.

- Mitigation: Using humidity-controlled containers, proper packaging, and understanding the specific needs of the materials can prevent drying effects.

Potential Shrinkage

- Goods Affected: Leather, certain plastics, and other materials that may react to low humidity.

- Effect on Cargo: These materials may shrink, deform, or change shape due to the low humidity.

- Real-life Example: Leather goods like shoes or bags may change shape or size if not properly protected.

- Mitigation: Proper storage, handling, and packaging that consider the specific nature of these materials can prevent shrinkage.

Mitigation Strategies

- Gradual Acclimatization: Allowing the cargo to gradually adjust to the new environment can prevent shocks and damage.

- Anti-Static Packaging: Utilizing materials that prevent static buildup can protect sensitive electronic components.

- Proper Handling: Understanding the specific needs of the cargo and handling it with care can prevent damage during unloading.

- Climate-Controlled Environments: If necessary, using climate-controlled storage or transport can maintain optimal conditions for sensitive goods.

The arrival of cargo in a cold, low-humidity environment is a critical phase that requires careful planning, understanding, and execution. From protecting against static electricity to preventing drying and shrinkage, each challenge must be met with the right strategies and techniques.

By employing gradual acclimatization, anti-static packaging, proper handling, and climate-controlled environments, shippers can ensure that the goods arrive in perfect condition. It’s the final leg of a complex journey, where attention to detail and expertise make all the difference.

Understanding Relative Humidity and Its Effects

| Aspect | Description |

|---|---|

| High RH Effects | Increased moisture, corrosion, condensation, health risks in Thailand. |

| Low RH Effects | Decreased moisture, less corrosion, static electricity, shrinkage in the US. |

Relative humidity (RH) plays a vital role in the shipping process, affecting various types of cargo in different ways. The effects of high RH (as found in Thailand) and low RH (as found in the US) can be quite pronounced. Here’s a detailed examination of these effects:

Effects of High Relative Humidity (80% in Thailand)

- Increased Moisture Content:

- Goods Affected: Food, textiles, paper, and other moisture-sensitive items.

- Effect on Cargo: Absorption of moisture can lead to spoilage, mold growth, or loss of structural integrity.

- Real-life Example: Thai spices may clump together or lose flavor if not properly protected.

- Mitigation: Proper sealing, moisture barriers, and controlled environments can prevent these issues.

- Corrosion and Rust:

- Goods Affected: Metals, machinery, automobile parts, and other metallic items.

- Effect on Cargo: High humidity can accelerate corrosion and rusting processes.

- Real-life Example: Industrial machinery may require special coatings or treatments to prevent rust.

- Mitigation: Utilizing anti-corrosion materials, coatings, and controlled environments can minimize these risks.

- Condensation Issues:

- Goods Affected: Electronics, sensitive instruments, and other items vulnerable to water damage.

- Effect on Cargo: Condensation can cause malfunctions, short circuits, or permanent damage.

- Real-life Example: Cameras and other electronic devices may malfunction if exposed to condensation.

- Mitigation: Using anti-condensation materials, sealed packaging, and climate-controlled containers can protect these goods.

- Potential Health Risks:

- Goods Affected: Pharmaceuticals, medical supplies, and other health-related products.

- Effect on Cargo: High humidity can lead to the degradation of these products, affecting their efficacy and safety.

- Real-life Example: Insulin or other temperature-sensitive medications may lose potency.

- Mitigation: Specialized packaging, storage conditions, and climate-controlled containers can ensure product integrity.

Effects of Low Relative Humidity (30% in the US)

- Decreased Moisture Content:

- Goods Affected: Wood, organic materials, textiles, and other items that may dry out.

- Effect on Cargo: Drying can lead to brittleness, cracking, or other quality degradation.

- Real-life Example: Wooden musical instruments may lose their tune or crack.

- Mitigation: Using humidity-controlled containers, proper packaging, and understanding the specific needs of the materials can prevent drying effects.

- Less Risk of Corrosion:

- Goods Affected: Metals and other corrosion-prone materials.

- Effect on Cargo: Low humidity reduces the risk of rust and corrosion.

- Real-life Example: Metal sculptures or artwork may remain intact without special treatment.

- Mitigation: Regular monitoring and proper handling are usually sufficient in low humidity.

- Static Electricity:

- Goods Affected: Electronic components, machinery, and other sensitive items.

- Effect on Cargo: Low humidity can increase static electricity, causing malfunctions or damage.

- Real-life Example: Computer servers may require special grounding and packaging.

- Mitigation: Utilizing anti-static packaging, grounding, and other measures can protect against static electricity.

- Potential Shrinkage:

- Goods Affected: Leather, certain plastics, and other shrinkage-prone materials.

- Effect on Cargo: These materials may shrink or deform due to low humidity.

- Real-life Example: Leather jackets or accessories may change shape or size.

- Mitigation: Proper storage, handling, and packaging that consider the specific nature of these materials can prevent shrinkage.

Understanding the effects of relative humidity on different types of cargo is essential for successful shipping. From the high humidity of Thailand’s tropical climate to the dry air of the US, each environment presents unique challenges.

By recognizing these effects and employing the right strategies, shippers can ensure that goods reach their destination in optimal condition. It’s a complex interplay between nature and commerce, where knowledge, preparation, and attention to detail lead to success.

Mitigation Strategies

| Aspect | Description |

|---|---|

| Proper Packaging | Moisture barriers, sealed containers, anti-static materials. |

| Climate Control | Climate-controlled containers, refrigeration. |

| Understanding the Cargo | Assessing specific nature of goods, special handling. |

| Regular Monitoring | Humidity and temperature sensors, regular inspections. |

Mitigating the effects of relative humidity on cargo requires a combination of strategies. From proper packaging to regular monitoring, each approach plays a vital role in ensuring the goods reach their destination in optimal condition. Here’s a detailed look at these strategies:

Proper Packaging

- Moisture Barriers:

- What They Are: Materials that prevent moisture from reaching the goods.

- How They Work: By creating a barrier between the goods and the surrounding environment, they prevent moisture absorption.

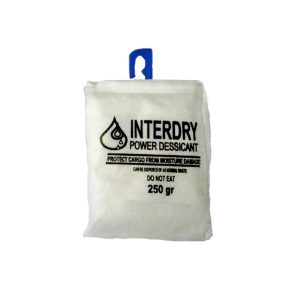

- Product Spotlight: InterDry Power Desiccant, a highly effective desiccant that absorbs excess moisture, keeping goods dry and protected.

- Applications: Ideal for food, textiles, electronics, and other moisture-sensitive items.

- Sealed Containers:

- What They Are: Containers that are sealed to prevent air and moisture exchange.

- How They Work: By sealing the container, they maintain a controlled environment inside.

- Applications: Useful for perishable goods, pharmaceuticals, and other sensitive items.

- Anti-Static Materials:

- What They Are: Materials that prevent the buildup of static electricity.

- How They Work: By dissipating static charges, they protect electronic components and machinery.

- Applications: Essential for computer parts, electronic devices, and other static-sensitive items.

Climate Control

- Climate-Controlled Containers:

- What They Are: Containers with controlled temperature and humidity.

- How They Work: By maintaining specific conditions, they protect goods from environmental extremes.

- Applications: Ideal for artwork, pharmaceuticals, perishable goods, and other climate-sensitive items.

- Refrigeration:

- What It Is: Cooling technology to maintain low temperatures.

- How It Works: By keeping temperatures low, it preserves perishable goods like food and certain medical supplies.

- Applications: Essential for fresh produce, meat, dairy, and other temperature-sensitive items.

Understanding the Cargo

- Assessing the Specific Nature of Goods:

- What It Is: Understanding the unique needs and characteristics of the goods being shipped.

- How It Works: By tailoring the packaging, handling, and shipping methods to the specific nature of the goods, shippers can prevent potential issues.

- Applications: Essential for valuable, fragile, or unique items like artwork, antiques, or custom-made products.

- Special Handling:

- What It Is: Providing extra care and attention to certain goods.

- How It Works: By handling the goods with care and using specialized equipment or techniques, shippers can prevent damage or degradation.

- Applications: Ideal for fragile items, sensitive instruments, and other goods that require special care.

Regular Monitoring

- Humidity and Temperature Sensors:

- What They Are: Devices that monitor the humidity and temperature inside the container.

- How They Work: By providing real-time data, they allow shippers to detect and address potential issues early.

- Applications: Useful for pharmaceuticals, perishable goods, and other sensitive items.

- Regular Inspections:

- What They Are: Scheduled checks and inspections of the goods and container.

- How They Work: By regularly inspecting the goods, shippers can ensure quality and address any issues promptly.

- Applications: Essential for long voyages, valuable goods, and other high-risk shipments.

Mitigating the effects of relative humidity on cargo is a multifaceted challenge that requires a combination of strategies. From the innovative use of products like InterDry Power Desiccant to the careful monitoring of conditions, each strategy plays a vital role in the successful shipping of goods.

By understanding the specific nature of the cargo, employing proper packaging, utilizing climate control, and conducting regular monitoring, shippers can navigate the complexities of international shipping with confidence and success.

Comparative Analysis

| Aspect | Loading (Thailand) | During Voyage | Arrival (US) |

| Temperature | High | Cooling Down | Cold |

| Humidity | High (80%) | Variable | Low (30%) |

| Moisture Content | Increased | Condensation Risk | Decreased |

| Corrosion Risk | Higher | Depends on Conditions | Lower |

| Static Electricity | Less Likely | Less Likely | More Likely |

| Potential Shrinkage | Less Likely | Possible | Likely |

Using tools like InterDry Power Desiccant is not just about protecting goods; it’s about respecting the delicate balance of nature and using our knowledge to bridge the gap between different worlds, different climates.

Conclusion

| Aspect | Description |

|---|---|

| Summary | Overview of challenges in cargo transportation from Thailand to the US. |

| Mitigation | Strategies to mitigate risks, including packaging, climate control, etc. |

| Final Thoughts | Reflection on the complex interplay between RH and cargo. |

Summary

The journey of cargo from Thailand’s humid climate to the drier environment of the US is a multifaceted process that presents unique challenges. From moisture content changes to static electricity issues, each phase of the voyage has its own set of obstacles. The effects are not limited to mere physical changes; they touch upon the very essence of quality, functionality, and value of the goods being transported.

Mitigation

Mitigating these risks is not a one-size-fits-all solution. It requires a combination of strategies:

- Proper Packaging: Utilizing moisture barriers, sealed containers, anti-static materials, and innovative products like InterDry Power Desiccant ensures the integrity of the goods.

- Climate Control: Employing climate-controlled containers and refrigeration maintains optimal conditions.

- Understanding the Cargo: Assessing the specific nature of goods and providing special handling tailors the care to the unique needs of each shipment.

- Regular Monitoring: Implementing humidity and temperature sensors and conducting regular inspections ensures early detection of potential issues.

By employing these strategies with precision and care, shippers can navigate the complexities of international shipping with confidence.

Final Thoughts

From the bustling ports of Bangkok to the sprawling harbors of Los Angeles, the interplay between relative humidity and cargo is a complex dance that requires attention, expertise, and care. It’s a journey that transcends mere logistics, weaving into the fabric of global commerce and human ingenuity.

The weather isn’t just something to chat about over a cup of coffee; it’s a critical factor in the success of your shipment. It’s a testament to our ability to understand and harness the forces of nature for our benefit. It’s about respecting the delicate balance of the environment and using our knowledge to ensure that goods reach their destination in perfect condition.

In the world of shipping, understanding relative humidity is not just a technical skill; it’s an art form that blends science, technology, and human insight. It’s a dance that celebrates our ability to adapt, innovate, and succeed in a world that’s constantly changing.

Whether it’s a shipment of exotic spices from the heart of Thailand or cutting-edge technology destined for the vibrant markets of the US, the mastery of relative humidity is a key to success. It’s a story of resilience, innovation, and the timeless pursuit of excellence.

Frequently Asked Questions

What is Relative Humidity (RH), and why is it important in shipping?

Relative Humidity (RH) is the ratio of the current humidity to the maximum humidity that the air can hold at a given temperature. In shipping, it’s vital because it affects various types of cargo, from food to electronics, leading to potential spoilage, corrosion, or other damages.

How does high humidity affect cargo in Thailand?

High humidity (around 80% in Thailand) can lead to increased moisture content, causing absorption in food, textiles, and paper. It can also accelerate corrosion in metals and create condensation issues in electronics.

What are the challenges during the cooling down phase of the voyage?

During the cooling down phase, the temperature inside the container may drop, leading to condensation formation. This can severely affect electronic goods and cause wood and organic materials to contract or deform.

What happens when cargo arrives in a cold, low-humidity environment like the US?

Arrival in a cold, low-humidity environment (30% in the US) can cause sudden exposure, static electricity risks, drying effects, and potential shrinkage in leather and certain plastics. Proper handling and packaging are essential to mitigate these risks.

What are some mitigation strategies for dealing with relative humidity in shipping?

Mitigation strategies include proper packaging (using moisture barriers and sealed containers), climate control (using climate-controlled containers and refrigeration), understanding the specific nature of the goods, and regular monitoring (using humidity and temperature sensors).

How can I protect my shipment from moisture?

You can protect your shipment from moisture by using products like InterDry Power Desiccant, which absorbs excess moisture, along with proper sealing, moisture barriers, and climate-controlled containers.

What are the effects of low relative humidity on cargo?

Low relative humidity (as in the US) can lead to decreased moisture content, drying out wood and organic materials, reducing the risk of rust and corrosion in metals, increasing static electricity, and causing potential shrinkage in leather and certain plastics.

How does weather impact the success of shipping?

Weather, particularly relative humidity, is a critical factor in shipping. It affects the quality, functionality, and value of the goods being transported. Understanding and managing these effects is essential for successful shipping.