A Container Desiccant Study on Temperature and Relative Humidity

Container Rain Risk Based on Climate

| Climate Zone | Temperature Range (°C) | Container Rain Risk |

|---|---|---|

| Tropical | 25-35°C | High |

| Temperate | 10-25°C | Moderate |

| Arid | 5-20°C | Low |

Table of Content

When shipping goods in containers, understanding the impact of temperature and relative humidity on the container’s environment is crucial to prevent damage to your cargo. In this article, we will explore three commonly used shipping routes and how these factors affect the environment inside shipping containers. We will also discuss the importance of using shipping container desiccants to protect your cargo from moisture-related damages.

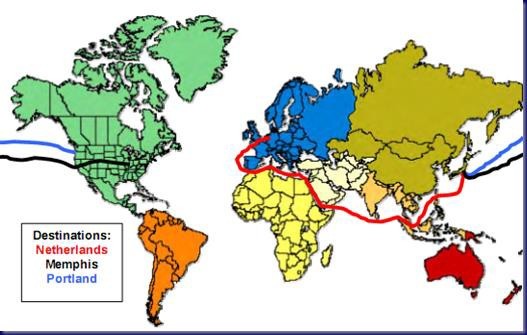

Three Typical Shipping Routes

To understand the impact of temperature and humidity on shipping containers, we have chosen three routes, namely Japan to the Netherlands, Japan to Memphis, and Japan to Portland.

Typical Conditions

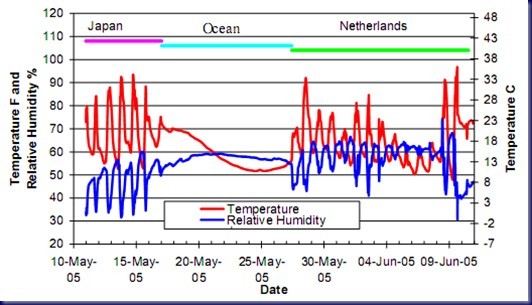

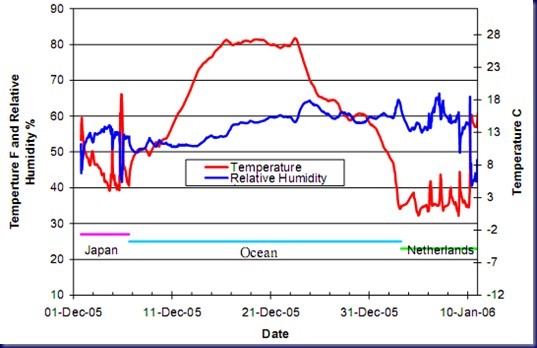

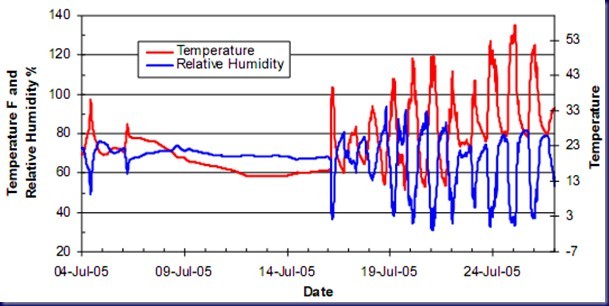

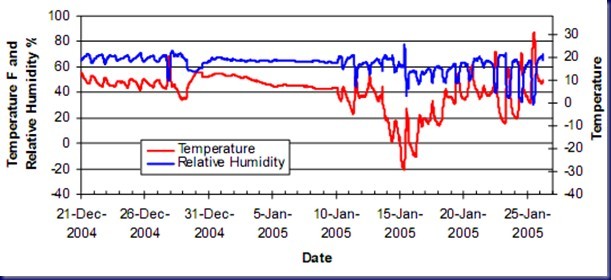

A standard shipment consists of three distinct stages. The first stage includes the time from container filling until the container is loaded onto a ship. This stage involves road transportation and brief periods of storage. Daily cycles of temperature and humidity are common. For example, a shipment from Japan to the Netherlands experiences temperature swings of 40° F [22°C] during this stage.

The second stage is the actual time at sea or aboard a ship. This stage may or may not be the longest part of the container’s journey. During this stage, daily cycles of temperature and humidity are usually minimal or nonexistent. Temperature changes are gradual, often occurring over days rather than hours. Occasionally, a single temperature/humidity cycle occurs as the ship makes stops along the route, but extreme conditions are rare.

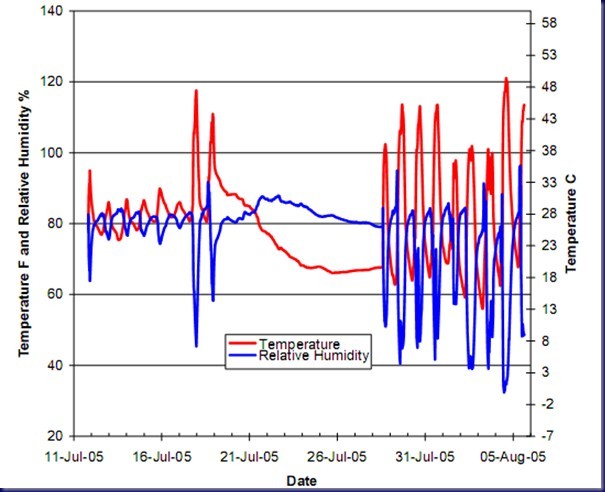

The final stage begins when the container is removed from the ship and continues until the recorder is removed during the freight unloading process. This stage may include varying periods of time spent in customs, on trains, on trucks, and in storage. Daily temperature and humidity cycles are common and may be extreme.

Impact of Relative Humidity on Product Integrity

| Relative Humidity (%) | Impact on Electronics | Impact on Textiles | Impact on Food |

|---|---|---|---|

| 40-60% | Minimal risk | Retains quality | Fresh, low spoilage |

| 60-80% | Corrosion risk begins | Risk of mold | Spoilage increases |

| 80-100% | High corrosion risk, malfunction | Severe mold risk, degradation | High spoilage, bacterial growth |

Extreme Conditions

Some of the most interesting recordings are the extreme conditions. The highest recorded temperature occurred on July 25, 2005, during a shipment from Japan to Memphis. The temperature reached 135° F [57° C] during the third stage of this shipment. On the other hand, the lowest recorded temperature occurred on January 15, 2005, also along the Japan to Memphis route. The temperature dropped to -21° F [-29° C], which is slightly beyond the recorder’s published temperature range.

The shipment with the highest relative humidity occurred during a trip from Japan to Portland. The relative humidity was recorded at 96% on August 5, 2005, while the container was on land. The most extreme humidity conditions are seen during periods of large daily temperature changes.

Effect of Temperature on Relative Humidity in Containers

| Temperature (°C) | Relative Humidity (%) | Impact on Goods |

|---|---|---|

| 15°C | 80% | Moderate moisture risk |

| 25°C | 90% | High moisture absorption |

| 35°C | 95% | Extreme risk for mold and damage |

Why Shipping Container Desiccants Matter

Understanding these temperature and humidity fluctuations is crucial for the proper use of shipping container desiccants. Desiccants, like InterDry Power Desiccant, Ecobag, and KeepDry, help control the humidity inside containers, preventing moisture damage to the cargo. By absorbing moisture from the air, they prevent the humidity from reaching dew point and condensing.

To maximize the effectiveness of shipping container desiccants, it is essential to monitor the temperature and relative humidity inside the container. By understanding the typical conditions and extreme situations that may arise during the shipping process, you can better protect your cargo from moisture-related damages.

Moisture Absorption Rates of Different Desiccants

| Desiccant Type | Moisture Absorption Rate (%) | Best Used For |

|---|---|---|

| Silica Gel | 35-40% | Short-term, low humidity environments |

| Calcium Chloride | 200% | High humidity, long-term shipping |

| Activated Clay | 40-50% | Moderate humidity, cost-effective |

Conclusion

In conclusion, being aware of the temperature and humidity fluctuations during your shipping journey is essential to ensure the safety and integrity of your cargo. By using shipping container desiccants and understanding their optimal usage, you can effectively safeguard your goods against moisture-related damages throughout the entire shipping process.

Frequently Asked Questions

What are shipping container desiccants?

Shipping container desiccants are moisture-absorbing materials used to control humidity inside shipping containers, preventing moisture damage to the cargo.

Why is it essential to monitor temperature and humidity inside shipping containers?

Monitoring temperature and humidity helps determine the proper use of shipping container desiccants and protects cargo from potential moisture-related damages.

How do shipping container desiccants work?

Shipping container desiccants work by absorbing moisture from the air, preventing humidity from reaching the dew point and condensing. This helps maintain a dry environment inside the container and protects the cargo from moisture damage.

What are some common shipping container desiccant products?

InterDry Power Desiccant, Ecobag, and KeepDry are popular shipping container desiccant products that help control humidity inside containers and prevent moisture damage to the cargo.

Can shipping container desiccants protect cargo during extreme temperature fluctuations?

Yes, shipping container desiccants can help protect cargo during extreme temperature fluctuations by absorbing moisture from the air and maintaining a dry environment inside the container. However, it’s essential to monitor the temperature and humidity conditions inside the container to ensure the desiccants are working effectively.

How can I ensure the optimal use of shipping container desiccants?

To ensure the optimal use of shipping container desiccants, monitor the temperature and humidity inside the container, choose the appropriate type and amount of desiccant based on your cargo and the shipping conditions, and follow the manufacturer’s guidelines for proper placement and use of the desiccants.

What is the ideal humidity level to prevent moisture damage in shipping containers?

The ideal humidity level inside a shipping container should be below 50% to effectively prevent moisture damage and condensation.

Can temperature fluctuations affect desiccant performance?

Yes, large temperature fluctuations can impact desiccant performance, as warmer temperatures increase the rate of moisture absorption.

How does container rain form?

Container rain occurs when the internal temperature of a shipping container drops, causing moisture to condense on the walls and ceiling.

Can desiccants be used in refrigerated containers?

Yes, desiccants are effective in refrigerated containers, especially when dealing with condensation and frost buildup.

How should desiccants be placed in shipping containers?

Desiccants should be evenly distributed throughout the container, particularly near areas where temperature changes are most likely, such as the ceiling and walls.

7 Tips for Maximizing the Efficiency of Your Shipping Container Desiccants

Case Studies: Real-World Success Stories with InterDry Power Desiccant, Ecobag, and KeepDry

The Impact of Humidity on Various Industries and How Desiccants Can Help

External links

https://www.yumpu.com/en/document/view/10676010/temperature-humidity-in-ocean-containers