Tackling Moisture Damage: The Hidden Threat in Shipping

Table of Contents

Introduction

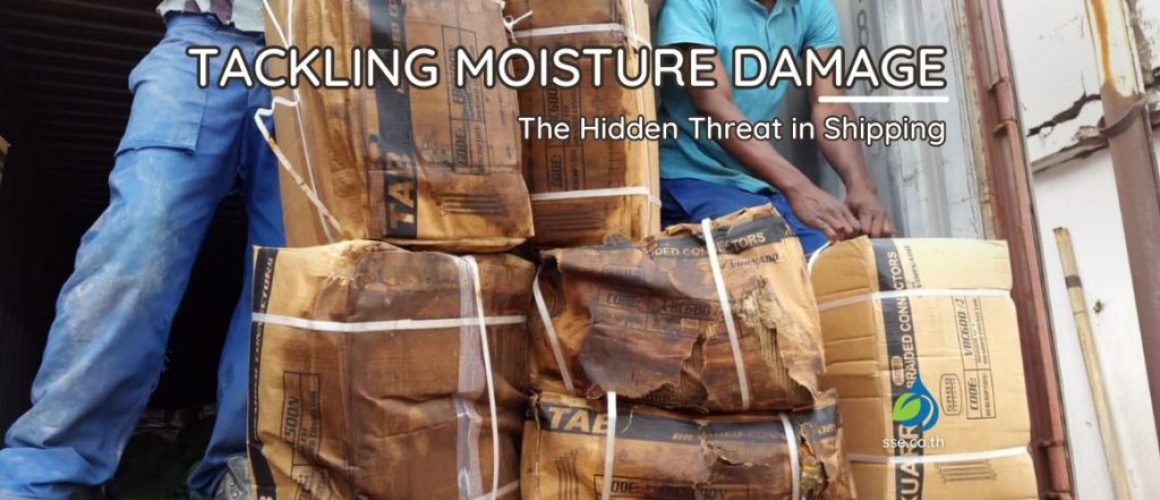

In the vast world of shipping, a hidden threat lurks that can compromise the integrity of goods and result in significant financial loss – moisture damage. This pervasive issue is often overlooked, yet its impact on global trade is substantial. Moisture damage can affect a wide range of goods, from organic materials like wood and food to manufactured goods such as electronics and machinery. The damage can manifest in various forms, including corrosion, mold growth, discoloration, and structural weakening, all of which can significantly reduce the value of the goods and potentially render them unsellable.

Moisture damage primarily occurs due to fluctuations in temperature and humidity within the shipping container. When warm, humid air cools down, it can no longer hold as much moisture, leading to the formation of condensation or ‘container rain.’ This moisture can then settle on the goods, leading to moisture-related problems. Similarly, goods that are hygroscopic, meaning they absorb moisture from the air, can also suffer from moisture damage if the relative humidity (RH) inside the container is too high.

Shipping containers, despite being designed to be watertight and robust, are not immune to the effects of moisture. The metal walls of the container can easily conduct heat, leading to temperature variations inside the container, especially when the container is exposed to different climates during its journey. These temperature fluctuations can exacerbate the problem of moisture damage.

Moreover, the issue of moisture damage is not confined to the transportation phase alone. It can occur at any point in the supply chain, from the moment the goods are packed until they reach their final destination. For instance, if goods are stored in a warehouse with high humidity levels or if they are loaded into the container in a humid environment, the risk of moisture damage increases.

In the case of wood and wood-based products, the risk of moisture damage is particularly high. Wood is a hygroscopic material, meaning it naturally absorbs and releases moisture depending on the RH of the surrounding air. If wood products are exposed to high humidity levels, they can absorb excess moisture, leading to problems such as warping, swelling, and fungal growth.

Despite the significant threat posed by moisture damage, it is a problem that can be effectively managed with the right strategies and tools. One such tool is the use of desiccants, like InterDry Power Desiccant, which can help control the moisture levels inside the shipping container, thereby protecting the goods from moisture-related damage.

Understanding Moisture-Related Damage in Shipping

Moisture-related damage in shipping is a pervasive issue that affects a wide range of goods, from organic materials like wood and food to manufactured products. This damage can occur in various forms, including corrosion, mold growth, warping, and discoloration, among others. It is primarily caused by the presence of excess moisture or humidity within the shipping container, leading to conditions that are conducive to these types of damage.

One of the most common types of moisture-related damage is corrosion, particularly for metal goods. When exposed to high humidity levels, metals can oxidize, leading to rust and degradation of the material. This can significantly reduce the value of the goods and may even render them unusable.

Another significant concern is the growth of mold and mildew, especially for organic materials like wood and food. These fungi thrive in moist conditions and can quickly spread, causing extensive damage. In addition to the physical harm, mold and mildew can also pose health risks, making the affected goods unsafe for consumption or use.

Warping and discoloration are other common forms of moisture-related damage. These are particularly prevalent in wood and paper goods, which can absorb moisture from the air. When this happens, the material can warp or change shape, and its color can fade or become uneven. Like corrosion and mold growth, this can significantly reduce the value of the goods and may make them unsuitable for their intended use.

Understanding the causes and types of moisture-related damage is the first step in preventing it. The primary factor is the relative humidity (RH) within the shipping container. When the RH is high, the air can hold more moisture, creating a humid environment. This is often exacerbated by temperature variations, which can cause the RH to fluctuate and lead to condensation, commonly referred to as “cargo sweating” or “container rain.”

Another contributing factor is the nature of the goods themselves. Some materials, such as wood and certain types of food, are hygroscopic, meaning they naturally absorb moisture from the air. When packed in a container, these goods can release this moisture, increasing the RH and the potential for damage.

Packaging can also play a role in moisture-related damage. Inadequate or inappropriate packaging can allow moisture to reach the goods, while also trapping it around them. This is particularly problematic for goods packed in containers for extended periods, where the moisture has ample time to cause damage.

The Science Behind Moisture Damage: Container Rain and Cargo Sweating

Two of the main culprits behind moisture damage in shipping containers are phenomena known as “container rain” and “cargo sweating.” Cargo sweating and container rain are two phenomena that occur due to changes in temperature and humidity within a shipping container.

Cargo sweat is primarily caused by the moisture content of the goods themselves. Goods of vegetable origin, such as coffee, rice, cereal products, lumber products, and various fruits, release water vapor into the container air while in transit. They establish an equilibrium moisture content based on their water content and biotic activity. If the container wall is cooled by the external air to below the dew point temperature of the internal air, sweat starts to form on the walls.

This process can become particularly intense in frosty weather as the goods still store considerable quantities of heat which maintain thermal circulation, constantly transporting water vapor from the goods to the container ceiling. In freezing weather, condensation may also be accompanied by immediate formation of ice or sublimation, promoting the build-up of water on the ceiling. When the temperature rises, instead of evaporating, the water drips down and causes wetting damage on the surface of the cargo.

Container rain, on the other hand, is a result of a steep temperature gradient between the cargo and the container wall. This gradient creates a “humidity motor” or cycle within the container. During this cycle, the container air cools down to below its dew point on the container wall, causing a proportion of the water vapor to condense. This air then returns to the cargo, where it warms up and picks up water vapor, before cooling back down again on the container wall. This cycle can lead to significant moisture damage if not properly managed.

Understanding these phenomena is crucial in the shipping industry, as they can lead to significant damage to the goods being transported, particularly hygroscopic goods that readily absorb moisture from their surroundings. This is where desiccants like InterDry Power Desiccant come into play. By absorbing excess moisture in the air, desiccants can help to maintain a stable humidity level within the container, preventing the formation of cargo sweat and container rain, and thereby preserving the quality of the goods.

The Role of Relative Humidity (RH) in Moisture Damage

Relative humidity, or RH, plays a significant role in the occurrence of moisture damage, influencing the amount of moisture air can hold and thus the potential for condensation.

Relative humidity (RH) is a measure of the amount of moisture in the air compared to the maximum amount of moisture the air could hold at the same temperature. It is expressed as a percentage. For instance, if the air is holding half the moisture it could hold at a particular temperature, the relative humidity is 50%.

When we talk about moisture damage in shipping containers, the concept of relative humidity becomes crucial. This is because the amount of moisture air can hold is dependent on temperature. Warm air can hold more moisture than cold air. So, if warm, moist air inside a shipping container cools down, it can’t hold as much moisture. The excess moisture then condenses into liquid water, leading to problems like container rain and cargo sweat.

The relationship between temperature, moisture, and relative humidity is often represented on a psychrometric chart. This chart is a graphical representation of the physical and thermodynamic properties of moist air at a constant pressure. It’s a valuable tool in understanding and predicting how changes in temperature, humidity, and pressure can lead to condensation and moisture damage.

In the context of shipping, the relative humidity inside the container can change due to fluctuations in temperature. For instance, during the day, the temperature inside the container can rise, causing the air to hold more moisture and lowering the relative humidity. However, at night, the temperature can drop, and the relative humidity can increase as the air’s moisture-holding capacity decreases. If the relative humidity reaches 100%, the air is saturated, and any further drop in temperature can cause the excess moisture to condense, leading to container rain or cargo sweat.

Therefore, understanding and controlling the relative humidity inside a shipping container is crucial in preventing moisture damage. This is where tools like hygrometers, which measure relative humidity, and desiccants, which absorb excess moisture, become essential. By monitoring the relative humidity and taking steps to control it, shippers can significantly reduce the risk of moisture damage and ensure the safe transportation of goods.

The Impact of Moisture Damage on Different Types of Goods

The effects of moisture damage can vary significantly depending on the type of goods being transported, with organic materials like wood being particularly susceptible.

Moisture damage in shipping can have a profound impact on a wide range of goods, with the severity and nature of the damage varying significantly depending on the type of goods being transported. Organic materials, such as wood and food, are particularly susceptible to moisture damage due to their inherent properties.

Wood, for instance, is a hygroscopic material, meaning it naturally absorbs and releases moisture in response to the surrounding environment. When exposed to high levels of humidity or direct contact with water, wood can absorb excessive moisture, leading to a range of issues. These can include warping, swelling, and shrinkage, which can alter the physical dimensions and structural integrity of the wood. Moreover, excessive moisture can also lead to the growth of mold and mildew, which not only damages the wood but can also pose health risks.

Food products, particularly fresh produce, are also highly susceptible to moisture damage. High humidity levels can accelerate the ripening process of fruits and vegetables, leading to over-ripening and spoilage. Moreover, moisture can promote the growth of mold and bacteria, posing significant food safety risks. Even packaged food products are not immune to moisture damage. For instance, moisture can cause the deterioration of packaging materials, potentially leading to contamination of the food product.

Manufactured goods, such as electronics and machinery, can also suffer from moisture damage. Electronic components are particularly sensitive to moisture as it can cause corrosion of metal parts, short-circuiting, and other electrical failures. Similarly, machinery and metal goods can rust and corrode when exposed to excessive moisture.

Textiles and clothing are another category of goods that can be significantly affected by moisture damage. Exposure to high humidity can lead to the growth of mold and mildew, causing discoloration and unpleasant odors. Moreover, moisture can cause certain fabrics to shrink or stretch, affecting the quality and fit of the garments.

In the case of paper goods, such as books, documents, and packaging materials, moisture can be particularly destructive. Paper absorbs moisture from the air, which can lead to warping, discoloration, and the breakdown of the paper fibers. Moreover, ink on paper can smudge or run when exposed to moisture, rendering printed materials illegible.

Moisture damage can have a wide range of impacts on different types of goods, affecting their quality, functionality, and overall value.

Tackling Moisture Damage: The Importance of a Watertight Container

One of the first lines of defense against moisture damage is ensuring the use of a watertight container that can protect goods from external water sources.

The shipping industry is a complex network, with the shipping container serving as a crucial component. These containers are the primary defense against moisture damage, shielding the goods from external water sources. However, the effectiveness of this defense is not just about having a container; it’s about having a watertight container.

A watertight container is designed to prevent water intrusion, ensuring that the goods inside stay dry and safe. This is particularly vital when transporting goods susceptible to moisture damage, such as organic materials like food and wood, as well as manufactured goods like electronics and machinery. However, the effectiveness of a watertight container can be compromised if it’s not properly maintained or if it’s damaged. Therefore, conducting a thorough inspection of the container before loading the goods is crucial.

The Container Handbook provides valuable insights into the characteristics of various goods and their suitability for container transport. For instance, organic materials, due to their nature, can be highly susceptible to moisture damage. Therefore, when transporting such goods, using a watertight container to protect them from external moisture is essential.

Moreover, the handbook also emphasizes the importance of adhering to specific export and import regulations for certain goods. These regulations ensure that the goods have been responsibly sourced and handled, further emphasizing the need for responsible practices in the shipping industry.

However, having a watertight container is just one part of the solution. It’s also essential to control the internal environment of the container. This includes maintaining the right temperature and humidity levels inside the container to prevent the formation of condensation, which can lead to moisture damage. This is where the use of desiccants, like InterDry Power Desiccant, comes into play. These desiccants can effectively control the moisture levels inside the container, further protecting the goods from moisture damage.

Humidity Calculator

Beyond the Container: The Role of Climate-Controlled Loading Docks

While the container itself is crucial, the environment in which it is loaded, such as climate-controlled loading docks, can also significantly influence the potential for moisture damage.

One of the key components of a climate-controlled loading dock is the type of doors used. Doors designed for these environments are built to withstand the wear and tear of heavy traffic, including pallet jacks, pedestrians, and carts. They come in a variety of types, including those with sturdy wood cores for general use and insulated foam core or semi-flexible doors for temperature zone separation. These doors help maintain the climate-controlled environment within the loading dock, preventing the ingress of external air that could disrupt the temperature and humidity levels.

In addition to maintaining a consistent environment, these doors are also designed for durability and longevity. They can withstand the bumps and bruises of daily operations, ensuring that they continue to function effectively over time. Furthermore, they are available in a wide range of color options and can be custom-sized to fit the specific requirements of the loading dock.

The use of climate-controlled loading docks is particularly beneficial when dealing with goods that are sensitive to moisture, such as electronics, textiles, and certain types of food products. By maintaining a consistent environment during the loading and unloading process, these docks can help prevent the formation of condensation and subsequent moisture damage, ensuring that goods reach their destination in the best possible condition.

The Power of Desiccants in Managing Moisture

Desiccants emerge as a powerful tool in the battle against moisture damage, capable of absorbing excess moisture and maintaining a stable environment within the container.

Desiccants are substances that are used to absorb moisture from the surrounding environment, thus reducing the humidity level in that environment. They work by a process called adsorption, which is the adhesion of atoms, ions, or molecules from a gas, liquid, or dissolved solid to a surface. This creates a film of the adsorbate (the molecules or atoms being accumulated) on the surface of the adsorbent (the desiccant).

In the context of shipping, desiccants are often used to control the humidity levels inside shipping containers. When placed inside a container, the desiccant will start to adsorb the moisture present in the air. This helps to maintain a low relative humidity, reducing the risk of condensation forming on the walls of the container and subsequently on the cargo itself.

The effectiveness of a desiccant will depend on several factors, including the type of desiccant used, the amount of desiccant used, the duration of exposure, and the specific conditions inside the container, such as temperature and initial humidity level. One of the most commonly used desiccants in shipping is silica gel, which is known for its high adsorption capacity. However, other types of desiccants, such as activated alumina, molecular sieves, and calcium chloride, are also used.

InterDry Power Desiccant is a particularly effective solution for managing moisture in shipping containers. It has a high adsorption capacity, meaning it can absorb a significant amount of moisture, and it also has the advantage of not releasing the absorbed water even when fully saturated. This is because the absorbed water is converted into a gel, preventing it from leaking out and potentially damaging the cargo.

By using a desiccant like InterDry Power Desiccant, shippers can significantly reduce the risk of moisture damage to their cargo, ensuring that it arrives at its destination in the best possible condition. This is particularly important for goods that are sensitive to moisture, such as electronics, textiles, and certain types of food products.

Case Study: Successful Prevention of Moisture Damage

Let’s delve into a real-world example of how the right strategies, including the use of desiccants, can successfully prevent moisture damage during shipping.

In the global shipping industry, every cargo shipment presents its unique set of challenges. These challenges are amplified when the cargo involves a diverse range of goods, each with its specific requirements for optimal storage and transportation conditions. In this case, we are looking at a shipment from Thailand to Europe, a journey spanning thousands of miles and crossing multiple climate zones. The cargo includes electronics, textiles, and food products, each susceptible to damage from excessive moisture. The electronics can suffer from corrosion of components, textiles can develop mildew, and food products can spoil, all due to moisture damage. This scenario underscores the importance of effective moisture management strategies in ensuring the safe and successful transportation of goods.

The primary challenge in this scenario is managing moisture levels within the shipping container. The journey from Thailand to Europe involves crossing different climate zones, each with its unique temperature and humidity levels. These fluctuations can lead to the formation of container sweat or cargo sweat, potentially causing moisture damage to the goods. The diverse nature of the goods adds another layer of complexity. Electronics, textiles, and food products each have different tolerances to moisture. Therefore, a one-size-fits-all approach would not be effective. The challenge lies in implementing a moisture management strategy that caters to the needs of all the different goods within the container.

Addressing the challenge required a multi-faceted approach. First, watertight containers were used to protect the cargo from external sources of moisture. These containers were thoroughly inspected before loading to ensure they were free from leaks or damage that could allow water ingress. Second, climate-controlled loading docks were used to minimize the exposure of the goods to fluctuating environmental conditions during the loading process. This helped to reduce the risk of condensation forming when the goods were moved from the controlled environment of the warehouse to the shipping container. Finally, and most importantly, container desiccants were used to control the moisture levels within the container during the journey.

Container desiccants play a crucial role in this strategy. These powerful tools are designed to absorb excess moisture from the air within the container, effectively reducing the relative humidity and preventing the formation of container sweat or cargo sweat. For this shipment, InterDry Power Desiccant was used. These desiccants were strategically placed within the container to ensure optimal coverage. Special attention was given to the placement of desiccants near the goods most susceptible to moisture damage. Throughout the journey, the InterDry Power Desiccant worked to maintain a stable, low-humidity environment within the container, protecting the goods from potential moisture damage.

Conclusion: The Imperative of Tackling Moisture Damage in Shipping

The successful transportation of goods, as illustrated in our case study, underscores the importance of a comprehensive strategy to tackle moisture damage in shipping.

Moisture damage in shipping is a pervasive issue that can compromise the integrity of a wide range of goods, leading to significant financial loss and customer dissatisfaction. However, as our case study demonstrates, this challenge can be effectively managed with the right strategies and tools.

The use of watertight containers and climate-controlled loading docks plays a crucial role in protecting goods from external sources of moisture and fluctuating environmental conditions. However, the real game-changer in the battle against moisture damage is the use of container desiccants, such as InterDry Power Desiccant. These powerful tools work tirelessly to absorb excess moisture within the container, maintaining a stable, low-humidity environment that is conducive to the safe transportation of goods.

As we move forward in an increasingly globalized world, the demand for effective shipping solutions will continue to grow. The ability to manage moisture levels within shipping containers will remain a critical factor in ensuring the successful transportation of goods. By understanding the science behind moisture damage and employing effective strategies to tackle it, we can ensure that goods reach their destination in the best possible condition, regardless of the distance or environmental conditions they must endure.

Call to Action

If you’re involved in the shipping industry and are looking for effective ways to tackle moisture damage, consider the power of desiccants and the importance of a comprehensive moisture management strategy.

Moisture damage is a pervasive issue in the shipping industry, affecting a wide range of goods and leading to significant financial losses. But it doesn’t have to be this way. With the right tools and strategies, you can effectively manage moisture levels in your shipping containers, ensuring that your goods reach their destination in the best possible condition.

One of the most effective tools in this battle against moisture damage is InterDry Power Desiccant. This powerful desiccant works tirelessly to absorb excess moisture within the container, maintaining a stable, low-humidity environment that is conducive to the safe transportation of goods.

So, if you’re ready to take the next step in protecting your goods from moisture damage, consider InterDry Power Desiccant. It’s a small investment that can make a big difference in the quality of your goods and the success of your shipping operations.

Don’t let moisture damage compromise the quality of your goods. Take action today and discover the power of InterDry Power Desiccant. Your goods – and your customers – will thank you. Contact us Call: 0858124188

Frequently Asked Questions

What is moisture damage in shipping?

Moisture damage in shipping refers to the harm caused to goods in transit due to excess moisture or humidity within the shipping container. This can lead to issues such as mold, corrosion, warping, and other forms of degradation.

What causes moisture damage in shipping containers?

Moisture damage in shipping containers is primarily caused by two phenomena: container rain and cargo sweating. Both are results of changes in temperature and humidity within the container.

What is container rain?

Container rain is a phenomenon where condensation forms on the ceiling of the shipping container and then drips onto the cargo, potentially causing damage.

What is cargo sweating?

Cargo sweating occurs when the cargo’s temperature is lower than the dew point of the air. This causes condensation to form directly on the surface of the cargo.

How does relative humidity affect moisture damage?

Relative humidity (RH) is a measure of how much moisture the air is holding relative to the maximum amount it could hold at a given temperature. High RH can increase the risk of condensation and moisture damage.

What types of goods are most susceptible to moisture damage?

Organic materials like wood, food, and textiles are particularly susceptible to moisture damage. However, even non-organic materials like metals can be affected, as moisture can lead to corrosion.

How can a watertight container help prevent moisture damage?

A watertight container can protect goods from external sources of water, such as rain or sea spray, thereby reducing the risk of moisture damage.

What is the role of climate-controlled loading docks in preventing moisture damage?

Climate-controlled loading docks can help maintain a stable temperature and humidity level when loading the container, reducing the risk of condensation and moisture damage.

How do desiccants help prevent moisture damage?

Desiccants are substances that absorb moisture from the air. By placing desiccants in a shipping container, you can reduce the humidity level and thus the risk of moisture damage.

What are some examples of desiccants used in shipping?

One example of a desiccant used in shipping is silica gel. Another is InterDry Power Desiccant, which is particularly effective at absorbing moisture.

Can moisture damage be completely prevented?

While it’s difficult to completely eliminate the risk of moisture damage, it can be significantly reduced through strategies like using watertight containers, climate-controlled loading docks, and desiccants.

What should I do if my cargo has suffered moisture damage?

If your cargo has suffered moisture damage, it’s important to document the damage, notify the relevant parties (such as your insurance company), and take steps to prevent further damage.

How does temperature affect moisture damage?

Changes in temperature can lead to changes in relative humidity and the dew point, which can in turn lead to condensation and moisture damage.

What is the dew point?

The dew point is the temperature at which air becomes saturated with water vapor. If the temperature of the cargo or the container’s interior falls below the dew point, condensation can form.

Read more

The Timber and Furniture Industry in Thailand: The Role of InterDry Power Desiccant

The Mystery of Moisture Problems in Shipping Containers