Hygroscopic Goods and Their Role in Sweat Formation in Shipping Containers

Table of Contents

Introduction

In the shipping industry, understanding the nature of the goods being transported is crucial, especially when those goods are hygroscopic and contribute to sweat formation in containers. Hygroscopic goods, by their very nature, have a high affinity for moisture. They can absorb water from the surrounding environment, and under certain conditions, release it back. This characteristic can lead to the formation of what is known as ‘container sweat’ or ‘cargo sweat’, a phenomenon that can cause significant damage to the cargo and result in substantial financial losses.

The term ‘hygroscopic’ comes from the Greek word ‘hygros’, meaning wet or moist, and ‘scopic’, meaning to look or observe. In essence, hygroscopic goods are those that ‘seek out’ moisture. They include a wide range of items, from food products such as sugar, salt, and flour, to textiles, wood, and certain types of metal. Even the packaging materials used in shipping, like cardboard and certain types of plastic, can be hygroscopic.

When these goods are packed into a shipping container, they bring with them a certain amount of moisture. If the external temperature drops, the air inside the container can reach its dew point, the temperature at which the air becomes saturated with water vapor. When this happens, the excess water vapor condenses on the cooler surfaces of the container and the cargo, leading to the formation of container sweat.

This can have a detrimental effect on the cargo. For instance, food products can become moldy, metals can rust, and textiles can develop mildew. In addition, changes in moisture levels can cause wooden items to warp or crack, and paper products to become damp and discolored. In severe cases, cargo sweat can even lead to the structural failure of packaging, causing goods to become loose and potentially leading to damage during transit.

The financial implications of this can be significant. Not only is there the direct cost of the damaged goods to consider, but also the potential loss of future business. If customers receive damaged goods, they may choose to take their business elsewhere in the future. Furthermore, there may be additional costs associated with disposing of damaged goods, particularly if they are of a type that requires special disposal procedures.

Understanding the hygroscopic nature of goods and how it contributes to sweat formation is the first step in preventing this kind of damage. By taking into account the type of goods being shipped, the conditions they will be transported under, and the length of the journey, appropriate measures can be put in place to control moisture levels within the container and prevent the formation of container sweat.

In the following sections, we will delve deeper into the concept of hygroscopic goods, exploring how different types of goods contribute to sweat formation, and discussing strategies for preventing this phenomenon. We will also look at the role of desiccants, such as InterDry Power Desiccant, in controlling moisture levels within shipping containers, and present a case study demonstrating the successful prevention of cargo sweat. By the end of this article, you will have a comprehensive understanding of the challenges posed by hygroscopic goods and how to overcome them.

Understanding Hygroscopic Goods

Hygroscopic goods are materials that readily attract moisture from their surroundings, a characteristic that can significantly influence the humidity levels inside a shipping container. These goods, due to their inherent properties, can absorb water vapor from the air, hold it, and under certain conditions, release it back into the environment. This ability to interact with moisture makes hygroscopic goods a key player in the formation of cargo sweat, a phenomenon that can lead to significant damage to goods during shipping.

The term ‘hygroscopic’ is derived from the Greek words ‘hygros’ meaning ‘wet’ or ‘moist’, and ‘scopos’ meaning ‘looking at’ or ‘observing’. Essentially, hygroscopic materials are those that ‘seek out’ or ‘observe’ moisture. They are like sponges, soaking up water vapor from the air until they reach a state of equilibrium with their environment. This equilibrium is dynamic, meaning that as the conditions in the environment change, so too does the amount of moisture the goods absorb or release.

Hygroscopic goods encompass a wide range of materials. Many food items, such as sugar, salt, coffee, and certain grains, are hygroscopic. These goods can absorb moisture to the point where they become damp or even dissolve. Textiles, including cotton, wool, and certain synthetic fibers, can also absorb significant amounts of moisture, which can lead to the development of mildew or other forms of decay. Wood, paper products, and even certain metals can be hygroscopic, absorbing moisture that can lead to warping, discoloration, rust, and other forms of damage.

Even the packaging materials used in shipping can be hygroscopic. Cardboard, for instance, can absorb moisture, which can weaken its structure and lead to the collapse of boxes. Certain types of plastic wrap can also absorb water vapor, which can lead to condensation forming inside the packaging.

The hygroscopic nature of goods can have a significant impact on the conditions inside a shipping container. As these goods absorb moisture, they increase the humidity level in the air. If the temperature inside the container drops, this humid air can reach its dew point, leading to the formation of condensation or cargo sweat. This can result in a wide range of problems, from the development of mold and mildew to the corrosion of metal goods.

Understanding the hygroscopic nature of goods and how it contributes to the formation of cargo sweat is crucial for anyone involved in the shipping industry. By taking into account the hygroscopic properties of the goods being shipped, as well as the conditions they will be transported under, it is possible to implement strategies to control humidity levels inside shipping containers and prevent the formation of cargo sweat.

In the following sections, we will explore these strategies in more detail, looking at how to prepare hygroscopic goods for shipping, the role of desiccants in controlling humidity levels, and other measures that can be taken to prevent cargo sweat. We will also present a case study demonstrating the successful prevention of cargo sweat in a real-world shipping scenario. By the end of this article, you will have a comprehensive understanding of the challenges posed by hygroscopic goods and how to overcome them.

Examples of Hygroscopic Goods

Numerous goods fall into the category of hygroscopic materials, many of which are commonly transported in shipping containers. These goods, due to their inherent properties, can absorb and hold moisture from the environment, and under certain conditions, release it back. This interaction with moisture can significantly influence the humidity levels inside a shipping container, contributing to the formation of cargo sweat. Let’s delve into some examples of these hygroscopic goods.

Food Products

Many food items are hygroscopic, including sugar, salt, coffee, and certain grains. These goods can absorb moisture to the point where they become damp or even dissolve. For instance, anyone who has left a salt shaker out in a humid environment has likely witnessed this hygroscopic effect firsthand, as the salt absorbs moisture and clumps together. In a shipping container, these food products can significantly increase the humidity level, leading to potential cargo sweat.

Textiles

Textiles, including cotton, wool, and certain synthetic fibers, are also hygroscopic. These materials can absorb significant amounts of moisture, which can lead to the development of mildew or other forms of decay. This is particularly problematic for clothing manufacturers or retailers shipping large quantities of apparel. Without proper humidity control, these textiles can arrive at their destination damp, discolored, or even moldy.

Wood and Paper Products

Wood and paper products are another category of hygroscopic goods. These materials can absorb moisture, leading to warping, discoloration, and other forms of damage. In the case of wood, excessive moisture can also lead to the growth of wood-decaying fungi, which can compromise the structural integrity of wooden goods. Paper products, including books and documents, can become warped, discolored, or illegible if exposed to excessive moisture.

Metals

While it may seem counterintuitive, certain metals can also be considered hygroscopic. While metals do not absorb moisture in the same way as the other materials mentioned, they can react with moisture in the air to form rust. This is particularly true for iron and steel goods. In a humid shipping container, these metal goods can quickly become corroded, compromising their structural integrity and value.

Packaging Materials

Even the packaging materials used in shipping can be hygroscopic. Cardboard, for instance, can absorb moisture, which can weaken its structure and lead to the collapse of boxes. Certain types of plastic wrap can also absorb water vapor, which can lead to condensation forming inside the packaging.

Understanding the wide range of goods that are hygroscopic is the first step in managing the risk of cargo sweat. By recognizing the hygroscopic nature of these goods, shippers can take proactive steps to control humidity levels inside their containers, such as using desiccants or moisture-resistant packaging materials. In the following sections, we will explore these strategies in more detail, providing practical advice on how to prevent cargo sweat when shipping hygroscopic goods.

How Hygroscopic Goods Contribute to Sweat Formation

The moisture-attracting nature of hygroscopic goods can lead to an increase in humidity levels inside the container, contributing to the phenomenon known as cargo or container sweat. This process can be detrimental to the quality of goods, leading to potential damage or loss. To fully understand this, we need to delve into the science behind sweat formation and the role hygroscopic goods play in it.

The Science of Sweat Formation

Cargo sweat is essentially condensation that forms on the surface of the cargo or the interior of the shipping container. This occurs when warm, moist air comes into contact with cooler surfaces, causing the water vapor in the air to condense into liquid water. This is the same process that causes your glasses to fog up when you enter a warm building on a cold day.

In the context of a shipping container, this warm, moist air often comes from the goods themselves, particularly if they are hygroscopic. As these goods absorb moisture from the air, they can release it back into the environment under certain conditions, such as changes in temperature or pressure. This can lead to a cycle of absorption and release, which can significantly increase the humidity level inside the container.

Hygroscopic Goods and Humidity

Hygroscopic goods, due to their moisture-attracting nature, can significantly contribute to the humidity level inside a shipping container. As these goods absorb moisture from the air, they can increase the overall water vapor content in the container’s atmosphere. This is particularly true for goods that have a high moisture content to begin with, such as certain food products or textiles.

When these goods are loaded into a container, they can start to release this moisture into the air, particularly if the temperature inside the container rises. This can create a warm, moist environment that is ideal for the formation of cargo sweat.

Temperature Fluctuations and Sweat Formation

Temperature fluctuations can exacerbate the issue of cargo sweat, particularly in the case of hygroscopic goods. When the temperature inside the container rises, it can cause these goods to release some of the moisture they have absorbed. This increases the humidity level inside the container, making condensation more likely.

Conversely, when the temperature inside the container drops, the cooler surfaces can cause the water vapor in the air to condense, leading to the formation of cargo sweat. This is particularly problematic when containers are transported through different climate zones, as the temperature inside the container can fluctuate significantly.

The Impact of Cargo Sweat

The formation of cargo sweat can have a significant impact on the quality of goods. It can lead to issues such as mold, mildew, corrosion, and other forms of damage. This is particularly problematic for hygroscopic goods, as they can absorb this excess moisture, leading to further damage.

Understanding the role of hygroscopic goods in sweat formation is crucial for preventing this issue. In the next section, we will explore some strategies for managing the risk of cargo sweat when shipping these types of goods.

The Impact of Sweat Formation on Hygroscopic Goods

Sweat formation inside a shipping container can have detrimental effects on hygroscopic goods, leading to potential damage and financial loss. The moisture that accumulates on the surfaces of the container and the goods themselves can lead to a range of issues, from physical damage to the goods to the growth of mold and mildew. Understanding these impacts is crucial for anyone involved in the shipping and storage of hygroscopic goods.

Physical Damage to Goods

One of the most immediate impacts of sweat formation is physical damage to the goods. When moisture condenses on the surfaces of hygroscopic goods, it can cause them to become wet or damp. This can lead to a range of issues, depending on the nature of the goods.

For example, if the goods are made of materials that are sensitive to moisture, such as paper or certain types of textiles, they can become discolored, warped, or otherwise damaged. Similarly, if the goods are made of metal, the moisture can cause them to rust or corrode.

In some cases, the damage can be so severe that the goods are no longer usable. This can lead to significant financial loss, particularly if the goods are valuable or if a large quantity of goods is affected.

Growth of Mold and Mildew

Another major impact of sweat formation is the growth of mold and mildew. These fungi thrive in moist environments, so the condensation that forms inside a shipping container can provide the perfect conditions for them to grow.

When mold and mildew grow on hygroscopic goods, they can cause a range of issues. For one, they can cause the goods to have a musty, unpleasant smell. They can also cause discoloration and physical damage to the goods.

In addition, some types of mold can produce allergens, irritants, and in some cases, toxic substances known as mycotoxins. These can pose health risks to anyone who comes into contact with the goods.

Changes in the Properties of Goods

In some cases, the moisture absorbed by hygroscopic goods can cause changes in their properties. For example, if the goods are food products, the moisture can cause them to become stale or to spoil. Similarly, if the goods are chemical substances, the moisture can cause them to react or to degrade.

These changes can affect the quality of the goods, making them less valuable or even unusable. This can lead to financial loss, as well as potential issues with customer satisfaction and reputation.

Preventing the Impact of Sweat Formation

Given the potential impacts of sweat formation on hygroscopic goods, it’s crucial to take steps to prevent this issue. This includes using appropriate packaging materials, controlling the conditions inside the shipping container, and using desiccants to absorb excess moisture.

In the next section, we will explore these strategies in more detail, providing practical advice on how to protect hygroscopic goods from the detrimental effects of sweat formation.

Preventing Sweat Formation When Shipping Hygroscopic Goods

Hygroscopic goods, due to their nature, have a high affinity for moisture. This characteristic, while beneficial in certain applications, can pose a significant challenge when these goods are transported in shipping containers. The enclosed environment of a shipping container, combined with fluctuating external temperatures and humidity levels, can lead to the formation of cargo sweat. This can potentially damage the goods, leading to financial losses. However, with the right strategies in place, it is possible to minimize the risk of sweat formation when shipping hygroscopic goods.

One of the key strategies in preventing sweat formation is understanding the behavior of hygroscopic goods under different conditions. These goods, due to their moisture-attracting properties, can significantly influence the humidity levels inside a shipping container. For instance, a study on the transportation of sugar, a hygroscopic good, showed that the temperature in the interior of a stack of cargo adapts to changing external temperatures only very slowly. This slow adaptation can lead to a buildup of moisture, contributing to cargo sweat.

The study also revealed that the exposure of the goods to thermal stresses is determined by the size of the stack and its internal compactness. Stacks that are so dense that the ambient air cannot freely circulate within the stack do not readily adjust to external temperatures, and water vapor also cannot be dissipated. This leads to a buildup of moisture, contributing to the formation of cargo sweat.

To prevent this, it is crucial to ensure proper ventilation within the cargo stack. This can be achieved by arranging the goods in a manner that allows for the free circulation of air. This helps in dissipating the moisture, reducing the risk of sweat formation.

Another strategy is to use desiccants, such as InterDry Power Desiccant, which can absorb the excess moisture, maintaining a balanced humidity level inside the container. These desiccants can be placed strategically within the container to maximize their effectiveness.

Packaging also plays a crucial role in preventing sweat formation. Using moisture-resistant packaging materials can help protect the goods from the damaging effects of cargo sweat. Additionally, the use of vapor barriers can also help in reducing the risk of sweat formation.

Lastly, understanding the climatic conditions during transit can also help in planning the shipment of hygroscopic goods. By anticipating the changes in temperature and humidity levels, appropriate measures can be put in place to prevent sweat formation.

In conclusion, while the transportation of hygroscopic goods poses certain challenges, these can be effectively managed with the right strategies. By understanding the nature of these goods and the conditions under which sweat formation occurs, it is possible to ensure the safe and efficient transportation of hygroscopic goods.

The Role of Desiccants in Managing Moisture for Hygroscopic Goods

One of the most effective tools in managing moisture levels when shipping hygroscopic goods is the use of desiccants, such as InterDry Power Desiccant.

Desiccants are substances that are used to absorb moisture from the surrounding environment. They are commonly used in the shipping industry to control the humidity levels inside containers and prevent the formation of container sweat. Among the various types of desiccants available in the market, InterDry Power Desiccant stands out due to its high absorption capacity and efficiency.

InterDry Power Desiccant is a high-performance moisture absorber designed specifically for shipping containers. It has the ability to absorb more than 300% of its weight in moisture, ensuring that your cargo remains safe and dry throughout its journey. This is particularly important when shipping hygroscopic goods, as these materials are prone to absorbing moisture from the air, which can lead to an increase in humidity levels inside the container and the formation of container sweat.

The use of InterDry Power Desiccant can significantly reduce the risk of sweat formation and the potential damage it can cause to hygroscopic goods. By absorbing excess moisture from the air, it helps to maintain a stable and safe humidity level inside the container, protecting your cargo from the harmful effects of high humidity and condensation.

Moreover, InterDry Power Desiccant is easy to use and can be conveniently placed inside the container before shipping. It comes in the form of desiccant bags, which can be hung from the container’s ceiling or placed among the cargo. As the desiccant absorbs moisture, it turns into a gel, ensuring that the absorbed water is securely contained and does not leak back into the container environment.

In addition to using desiccants, it’s also important to properly package hygroscopic goods before shipping. This can include using moisture-resistant packaging materials and sealing the goods in airtight containers or plastic wraps. Furthermore, it’s advisable to monitor the weather conditions during the shipping period and take additional precautions if high humidity or temperature fluctuations are expected.

Case Study: Successful Shipping of Hygroscopic Goods

Let’s look at a real-world example of how proper preparation and the use of desiccants can successfully prevent sweat formation when shipping hygroscopic goods. In this case study, let’s consider the shipping of goods of vegetable origin, such as coffee, rice, cereal products, and lumber products. These goods are hygroscopic in nature and release water vapor into the container air while in transit. This water vapor can lead to the formation of sweat inside the container, especially when the container wall is cooled by the external air to below the dew point temperature of the internal air.

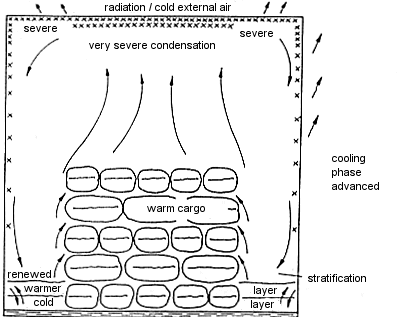

The intensity of sweat formation depends on the position of the moisture equilibrium, i.e., the difference between the air temperature and the dew point inside the container. It also depends on the daily drop in air temperature, with nocturnal radiation from the container walls being of particular significance. This process begins as soon as the ship leaves the subtropics in winter and may become particularly intense in frosty weather.

For instance, during a voyage into temperate latitudes, the goods still store considerable quantities of heat which maintain thermal circulation. This circulation constantly transports water vapor from the goods to the container ceiling. In freezing weather, condensation may also be accompanied by immediate formation of ice or sublimation (transition from the solid to gaseous state without passing through the liquid state), further promoting the build-up of water on the ceiling. When the temperature rises, instead of evaporating, the water drips down and causes wetting damage on the surface of the cargo.

Excessively rapid cooling of the outer layers of the stack may also result in wetting damage. In this case, condensation occurs within the stack on the cold, outer layer of the cargo stack. The effects of this are particularly disadvantageous for the goods. In bagged cargo, such damage is observed directly beneath the upper layer of bags, which appear to be dry from above. The damage is revealed when the first bags are lifted.

This case study highlights the importance of understanding the hygroscopic nature of the goods being shipped and the potential for sweat formation. It underscores the need for proper preparation and the use of desiccants like InterDry Power Desiccant to manage moisture levels and prevent sweat formation, thereby protecting the quality of the goods and preventing financial loss.

Conclusion: The Importance of Understanding Hygroscopic Goods in Shipping

Understanding the hygroscopic nature of certain goods and the role they play in sweat formation is crucial for anyone involved in the shipping industry. This knowledge is not just a theoretical concept, but a practical tool that can significantly impact the success of your shipping operations.

Hygroscopic goods, due to their inherent properties, can attract and hold moisture from the surrounding environment. This can lead to an increase in the humidity levels inside a shipping container, contributing to the phenomenon known as cargo or container sweat. This sweat, if not properly managed, can lead to the deterioration of the goods, causing financial losses and damaging the reputation of the shipper.

However, the challenges posed by hygroscopic goods are not insurmountable. With a clear understanding of these goods and the conditions that lead to sweat formation, shippers can take proactive steps to mitigate these risks. This includes the use of desiccants, such as InterDry Power Desiccant, to control the humidity levels inside the container. Proper packaging and insulation techniques can also be employed to protect the goods from the damaging effects of sweat.

Moreover, understanding the hygroscopic nature of goods can also help in making informed decisions about the shipping process. For instance, it can influence the choice of shipping routes, with shippers opting for routes that avoid extreme temperature fluctuations that can exacerbate sweat formation. It can also inform the choice of shipping containers, with shippers opting for containers with better insulation properties.

Call to Action

If you’re shipping hygroscopic goods and want to ensure they arrive at their destination in the best possible condition, consider using InterDry Power Desiccant to control moisture levels in your containers. But don’t stop there. It’s time to take action and make the necessary changes to your shipping practices to prevent the damaging effects of cargo sweat.

InterDry Power Desiccant is a high-performance moisture absorber designed specifically for shipping containers. It has the ability to absorb more than 300% of its weight in moisture, ensuring your cargo remains safe and dry throughout its journey. This is particularly important when shipping hygroscopic goods, which can attract and hold moisture from the surrounding environment, leading to increased humidity levels inside the container and the potential for cargo sweat.

But InterDry Power Desiccant is not just a product, it’s a solution. It’s a tool that can help you optimize your shipping operations, reduce the risk of cargo damage, and ultimately, increase the profitability of your business. And it’s a solution that’s within your reach.

So, are you ready to take the next step? Are you ready to ensure the safety of your hygroscopic goods and the success of your shipping operations? If so, contact us to learn more about InterDry Power Desiccant and how it can benefit your business. You can also contact our team of experts who are ready to answer any questions you may have and guide you through the process of integrating InterDry Power Desiccant into your shipping practices. Call 0858124188

Remember, in the world of shipping, knowledge is power. And with the right knowledge and the right tools, you can effectively manage the challenges posed by hygroscopic goods and ensure the success of your shipping operations. So don’t wait. Take action today and make InterDry Power Desiccant a part of your shipping solution.

Frequently Asked Questions

What are hygroscopic goods?

Hygroscopic goods are materials that readily attract and absorb moisture from their surroundings. This characteristic can significantly influence the humidity levels inside a shipping container, leading to the phenomenon known as cargo or container sweat.

How do hygroscopic goods contribute to sweat formation in shipping containers?

The moisture-attracting nature of hygroscopic goods can lead to an increase in humidity levels inside the container. As the temperature inside the container fluctuates, this excess moisture can condense on the walls of the container, leading to sweat formation.

What are some examples of hygroscopic goods?

Numerous goods fall into the category of hygroscopic materials. These include food products like sugar, salt, and flour, as well as wood, textiles, and certain types of metal.

What is the impact of sweat formation on hygroscopic goods?

Sweat formation inside a shipping container can have detrimental effects on hygroscopic goods. The excess moisture can lead to mold growth, corrosion, and other forms of damage, potentially resulting in significant financial loss.

How can I prevent sweat formation when shipping hygroscopic goods?

There are several strategies to minimize the risk of sweat formation, including proper ventilation, temperature control, and the use of desiccants. Desiccants, like InterDry Power Desiccant, can absorb excess moisture, helping to maintain optimal humidity levels inside the container.

What is InterDry Power Desiccant?

InterDry Power Desiccant is a high-performance moisture absorber designed specifically for shipping containers. It has the ability to absorb more than 300% of its weight in moisture, ensuring your cargo remains safe and dry throughout its journey.

How can I use InterDry Power Desiccant in my shipping operations?

InterDry Power Desiccant comes in bags that can be easily placed inside your shipping containers. The number of bags needed will depend on the size of the container and the nature of the goods being shipped.

Where can I purchase InterDry Power Desiccant?

You can purchase InterDry Power Desiccant directly from our website. If you have any questions or need assistance, our team of experts is ready to help.

Can InterDry Power Desiccant be used for non-hygroscopic goods?

Yes, InterDry Power Desiccant can be used for any type of cargo that could be affected by excess moisture. While it’s particularly beneficial for hygroscopic goods, it can also help protect other types of goods from the damaging effects of cargo sweat.

What should I do if I still have questions about shipping hygroscopic goods?

If you have more questions about shipping hygroscopic goods or using InterDry Power Desiccant, don’t hesitate to contact us at 0858124188. Our team of experts is ready to provide the information and support you need.

Read more

Preventing Cargo Sweat and Container Rain

The Intricacies of Transporting Tropical Fruits from Thailand

External links

https://www.containerhandbuch.de/chb_e/index.html

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้