Molecular Sieves for Hydrogen Purification: Removing Impurities for Industrial Applications

| Feature | Key Benefit |

|---|---|

| Hydrogen Purity | Enables fuel cell technology with highly pure hydrogen for optimal performance. |

| Impurity Removal | Effectively adsorbs CO, CO₂, and moisture, enhancing hydrogen quality. |

| Fuel Efficiency | Supports efficient hydrogen processing, reducing contamination for green energy. |

| Industrial Application | Essential for petrochemical and energy sectors where hydrogen purity is crucial. |

| Sustainability | Reduces environmental impact by supporting clean, green hydrogen production. |

Table Of Contents

Introduction: The Growing Need for Hydrogen Purification

| Key Point | Takeaway |

|---|---|

| Demand for Hydrogen Purity | As industries shift towards hydrogen energy, high-purity hydrogen becomes essential for safety and efficiency. |

| Importance Across Industries | Hydrogen purity is crucial in applications such as fuel cells, petrochemicals, and green energy production. |

| Role of Molecular Sieves | Molecular sieves are instrumental in achieving and maintaining high levels of hydrogen purity. |

As industries turn towards hydrogen as a clean energy source, achieving high hydrogen purity becomes essential for efficiency and safety. With rising demands in fuel cell technology, green energy, and petrochemicals, hydrogen quality is a priority to maintain equipment longevity and meet emission standards. Hydrogen purification ensures that contaminants are removed, enhancing the performance of applications where hydrogen is central, such as in fuel cells and green energy projects. In this context, molecular sieves offer a highly effective solution for achieving high purity levels, marking a breakthrough in hydrogen processing and fuel efficiency.

Hydrogen purity impacts not only operational efficiency but also the environmental sustainability of industries. By utilizing molecular sieves, which are designed to selectively adsorb contaminants, companies can achieve cleaner hydrogen, critical for fuel cell efficiency and petrochemical applications. This purification step is crucial for producing the high-quality hydrogen required for low-emission and renewable energy applications, supporting a shift towards cleaner technologies.

What Are Molecular Sieves and How Do They Work in Hydrogen Purification?

| Key Point | Takeaway |

|---|---|

| Selective Adsorption | Molecular sieves capture impurities based on molecular size, allowing only pure hydrogen to pass. |

| Types of Molecular Sieves | 5A and 13X molecular sieves are commonly used for hydrogen purification due to their specific pore sizes. |

| Efficient Impurity Removal | The structure of molecular sieves enables efficient removal of contaminants like CO and CO₂. |

Molecular sieves function through selective adsorption, which allows them to capture specific impurities from hydrogen gas streams. These sieves have precise pore structures that enable them to selectively adsorb molecules of particular sizes. For hydrogen purification, types like Molecular Sieves 5A and Molecular Sieves 13X are commonly used. Their pore sizes are specifically effective for removing impurities such as CO, CO₂, and moisture, while allowing hydrogen molecules to pass through freely, resulting in a higher purity hydrogen output.

13X molecular sieves are widely recognized for their ability to remove larger contaminants like CO₂ and certain sulfur compounds. Their larger pore size enables efficient adsorption of these impurities, making them ideal for hydrogen production environments where CO₂ or hydrocarbons need to be removed to prevent catalyst poisoning in downstream processes.

5A molecular sieves, on the other hand, are particularly suited for hydrogen purification that requires the removal of smaller molecules, such as water and CO. With their smaller pore size, 5A sieves are highly effective in selectively capturing impurities that would compromise hydrogen purity, especially in high-efficiency fuel cell applications. This specific size range allows 5A to target impurities that might be missed by larger-pore sieves, ensuring a refined level of purification.

The effectiveness of molecular sieves in purification is based on the principles of adsorption. As hydrogen flows through the sieves, contaminants adhere to the sieve surfaces due to the molecular interaction with the sieve’s pore structure. This process is highly efficient and can maintain consistent purity levels in hydrogen streams, which is essential for industries that depend on uninterrupted purity standards. For more insights into the role of molecular sieves as Pressure Swing Adsorbents in hydrogen purification, refer to Zeolites: Their Features as Pressure Swing Adsorbents and CO₂ Adsorption Capacity.

The Importance of Hydrogen Purity in Industrial Applications

| Key Point | Takeaway |

|---|---|

| Fuel Cell Applications | Impurities can damage fuel cells, making pure hydrogen essential for efficient energy output. |

| Standards in Green Energy | Molecular sieves help achieve hydrogen purity standards critical for sustainable energy solutions. |

| Impact on Efficiency and Equipment | High-purity hydrogen extends the life of industrial equipment and improves overall efficiency. |

High-purity hydrogen is essential for applications across multiple industries, from petrochemicals to renewable energy. In fuel cell technology, even minor impurities can degrade cell performance, leading to inefficiencies and shorter lifespans. This makes hydrogen purity a priority in green energy applications, where the focus is on achieving high fuel efficiency and minimal emissions. Molecular sieves enable industries to meet these stringent purity standards by removing contaminants and ensuring a stable hydrogen supply.

Beyond fuel cells, hydrogen purity is also critical in petrochemical applications. Contaminants like CO and CO₂ can hinder chemical reactions, leading to inefficiencies and higher operational costs. Using molecular sieves to ensure hydrogen quality supports cleaner, more efficient processes in these industries, contributing to both performance gains and compliance with environmental regulations.

How Molecular Sieves Remove Impurities from Hydrogen

| Key Point | Takeaway |

|---|---|

| Adsorption of CO and CO₂ | Molecular sieves effectively adsorb harmful impurities, ensuring high hydrogen purity. |

| Optimal Conditions for Use | Specific temperature and pressure conditions enhance the adsorption efficiency of molecular sieves. |

| Twin-Tower Systems | Advanced twin-tower systems maximize impurity removal in continuous hydrogen processing. |

Molecular sieves are highly effective at removing impurities, making them invaluable for ensuring the highest hydrogen quality standards. During the adsorption process, molecular sieves trap contaminants such as CO and CO₂ based on their molecular size, selectively capturing these impurities while allowing hydrogen to pass. This method is particularly effective in high-stakes environments like fuel cell systems, where maintaining purity is critical for operation.

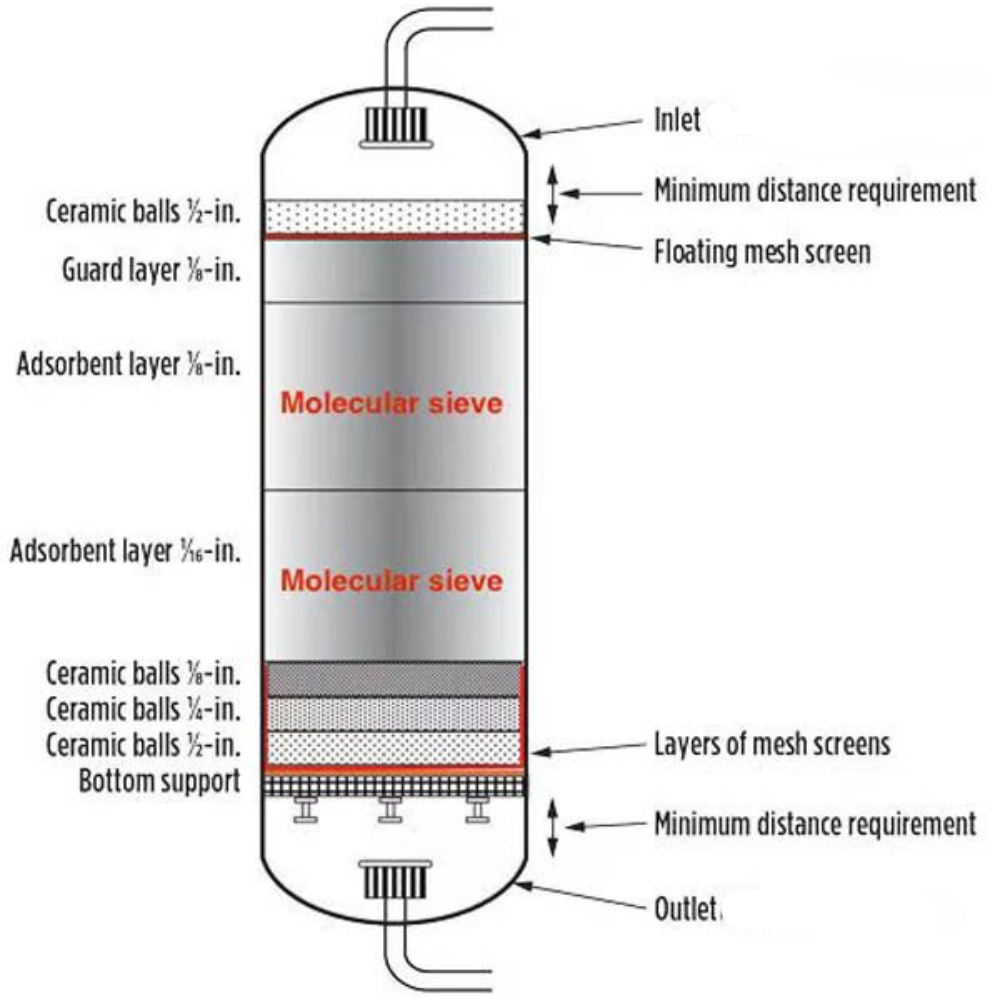

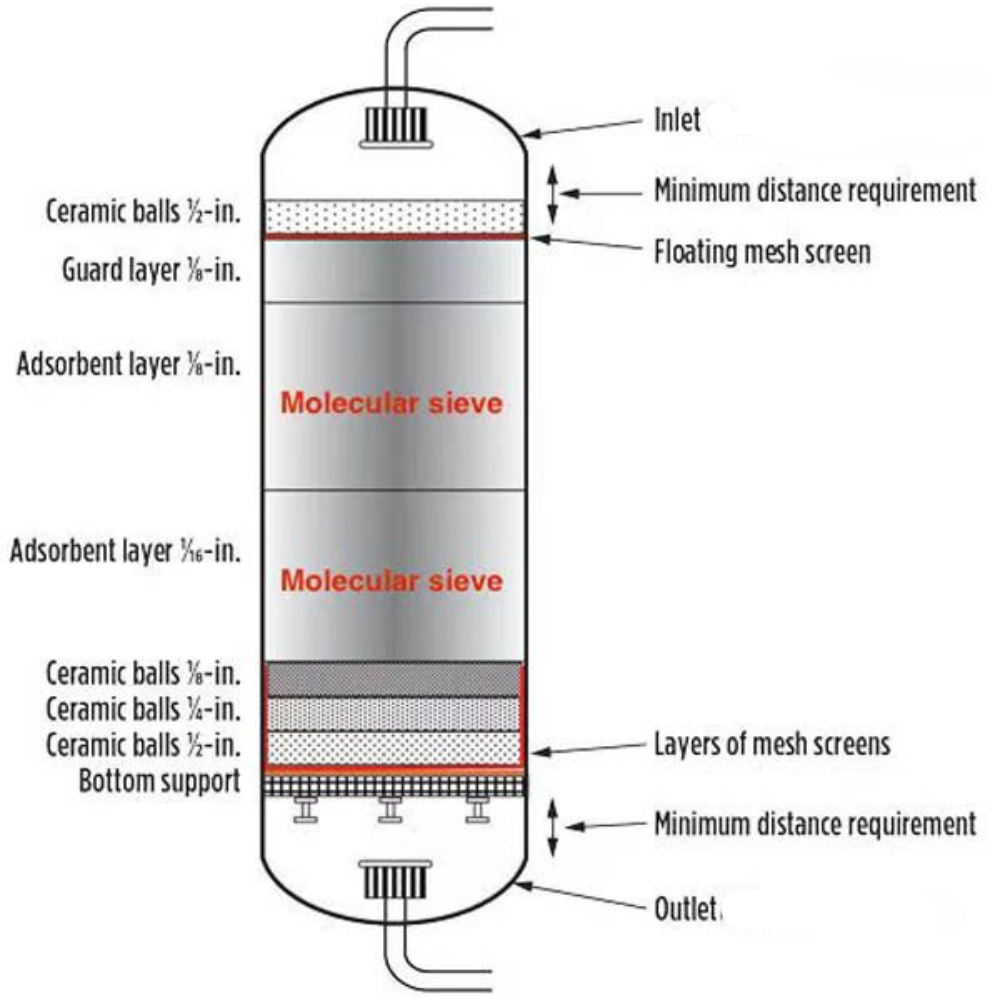

The conditions for optimal adsorption, such as pressure and temperature, are carefully controlled to maximize the molecular sieve’s efficiency. In some systems, twin-tower molecular sieve setups are used, where one tower adsorbs impurities while the other regenerates. This alternating process ensures continuous hydrogen purification, enhancing both the reliability and longevity of the sieve system.

The selective adsorption capabilities of 13X molecular sieves are invaluable for capturing larger impurities like CO₂, water, and even sulfur compounds, which are essential in achieving the purity required for hydrogen used in energy applications. 13X is often chosen when a broader range of impurities needs to be removed, making it suitable for systems with diverse contamination profiles.

Meanwhile, 5A molecular sieves are highly selective for smaller molecules like CO and water, providing a precision-focused approach to hydrogen purification. This targeted adsorption is ideal for hydrogen processing, where even minimal impurities can hinder fuel cell efficiency or damage sensitive equipment. By combining 5A and 13X in dual-stage systems, industries can achieve comprehensive impurity removal, addressing both smaller and larger molecules effectively.

Key Benefits of Using Molecular Sieves for Hydrogen Purification

| Key Point | Takeaway |

|---|---|

| High Adsorption Capacity | Molecular sieves offer high capacity for capturing impurities, supporting efficient purification. |

| Selectivity and Durability | They are highly selective for contaminants and durable, allowing extended use in industrial applications. |

| Sustainability Benefits | Using molecular sieves aligns with green energy goals by ensuring cleaner hydrogen production. |

The benefits of molecular sieves in hydrogen purification extend beyond just impurity removal. Their high adsorption capacity and selectivity make them ideal for applications requiring ultra-pure hydrogen, such as in fuel cells. This increased purity leads to reduced equipment maintenance and enhanced fuel efficiency, directly benefiting industries focused on green energy solutions.

Moreover, molecular sieves support sustainability efforts by allowing industries to produce clean hydrogen efficiently. As hydrogen gains traction as a renewable fuel, molecular sieves enable companies to achieve high-purity standards with minimal environmental impact. The durability and reliability of these sieves make them a cost-effective and sustainable choice for long-term hydrogen purification.

5A molecular sieves offer high selectivity and adsorption efficiency for smaller impurities, which can be critical for applications where even minute amounts of CO or water need to be removed. Their use in hydrogen purification extends the life of equipment, reduces the risk of contamination, and ultimately improves fuel efficiency by delivering a highly refined hydrogen product.

13X molecular sieves provide broader adsorption capabilities, making them suitable for processes where hydrogen must be free from a range of impurities, including larger molecules like CO₂ and sulfur compounds. The versatility and adsorption strength of 13X allow it to handle various contaminants efficiently, making it a go-to solution for diverse hydrogen purification needs in petrochemical and renewable energy applications.

Real-World Applications of Molecular Sieves in Hydrogen Purification

| Key Point | Takeaway |

|---|---|

| Fuel Cell Technology | Molecular sieves enable the production of high-purity hydrogen, essential for reliable fuel cell operation. |

| Petrochemical Processing | Purified hydrogen supports efficient petrochemical reactions, reducing contaminants in end products. |

| Green Hydrogen Production | Molecular sieves enhance the quality of hydrogen used in renewable energy applications. |

Molecular sieves are already making a significant impact in various real-world hydrogen purification applications. In fuel cell technology, pure hydrogen is essential to ensure consistent, reliable energy output, which molecular sieves help achieve by removing contaminants that could hinder performance. Fuel cells power a variety of clean energy vehicles and industrial equipment, underscoring the importance of hydrogen purity for green energy.

In applications like fuel cell technology, both 5A and 13X molecular sieves serve complementary roles. 5A sieves are exceptional for removing CO and water vapor, contaminants that can significantly reduce fuel cell efficiency and lifespan. Using 5A ensures that hydrogen feeding into fuel cells is free of these smaller contaminants, safeguarding against performance issues.

13X molecular sieves excel in applications that require removing a broader spectrum of contaminants, including CO₂, which is a frequent byproduct in hydrogen streams. In petrochemical processes and renewable hydrogen production, 13X sieves help ensure that hydrogen meets stringent quality standards by removing impurities that could impact downstream processing or environmental compliance.

In the petrochemical industry, hydrogen purification ensures that downstream processes remain efficient and environmentally compliant. Molecular sieves play a role here by adsorbing impurities and protecting sensitive catalytic processes. For those interested in learning more about the versatility of molecular sieve technology, see our post on Key Molecular Sieve Processes.

Technical Metrics and Performance Standards in Hydrogen Purification

| Key Point | Takeaway |

|---|---|

| Adsorption Capacity | High adsorption capacity is a critical factor in the effectiveness of molecular sieves for hydrogen purification. |

| Pore Size Distribution | Specific pore sizes (e.g., 5A, 13X) are chosen based on the types of impurities needing removal. |

| Compliance with Standards | Molecular sieves help achieve industry standards for hydrogen purity, ensuring safe and effective use. |

For hydrogen purification, molecular sieves are evaluated on their ability to meet strict performance standards and technical benchmarks. Metrics such as adsorption capacity, pore size distribution, and regeneration efficiency are critical in determining the effectiveness of molecular sieves in specific applications. Molecular sieves designed for hydrogen purification need to maintain high adsorption capacity and selective pore sizes to maximize impurity removal.

These metrics not only influence molecular sieve selection but also determine operational efficiency in industries like petrochemicals and green energy. Compliance with performance standards ensures that hydrogen purification systems meet industry demands and environmental regulations, providing a reliable source of clean hydrogen for industrial use.

Future Trends and Innovations in Molecular Sieves for Hydrogen Purification

| Key Point | Takeaway |

|---|---|

| Advanced Nanostructured Sieves | New developments focus on nanostructures to improve adsorption efficiency and selectivity. |

| Improved Regeneration Efficiency | Innovations aim to reduce environmental impact by enhancing sieve regeneration capabilities. |

| Role in the Hydrogen Economy | Molecular sieves will play a critical role in the growing green hydrogen market, supporting sustainability goals. |

As the demand for hydrogen grows, innovations in molecular sieve technology continue to push the boundaries of efficiency and sustainability. Emerging trends include nanostructured molecular sieves with enhanced adsorption capacities and selectivity, promising to make purification even more efficient. These advancements are particularly valuable in applications requiring large-scale hydrogen purification, such as green hydrogen production.

Research into molecular sieve regeneration efficiency is also gaining momentum, aiming to reduce operational costs and environmental impact. By developing sieves that require less energy for regeneration, industries can minimize their ecological footprint, aligning with global sustainability goals. The future of molecular sieves is bright, with innovations set to meet the expanding needs of the hydrogen economy.

Frequently Asked Questions

What are molecular sieves, and how do they work in hydrogen purification?

Molecular sieves are materials with a uniform pore structure that selectively adsorb molecules based on size. In hydrogen purification, they trap impurities like CO₂ and CO, allowing only high-purity hydrogen to pass through.

Why is hydrogen purity so important in fuel cell technology?

Fuel cells require extremely pure hydrogen to function efficiently. Impurities such as CO and CO₂ can poison the fuel cell’s catalyst, leading to reduced efficiency and potentially shortening the cell’s lifespan.

What role do molecular sieves play in hydrogen processing?

Molecular sieves remove impurities from hydrogen streams during processing. By adsorbing unwanted gases and moisture, they ensure that the hydrogen meets strict quality and purity standards.

How do molecular sieves enhance fuel efficiency in hydrogen applications?

Purified hydrogen improves the performance of fuel cells and other hydrogen-based applications. By using molecular sieves to remove contaminants, the efficiency of these systems is optimized, reducing fuel consumption and improving output.

Can molecular sieves remove both CO and CO₂ from hydrogen?

Yes, certain molecular sieves, like 13X and 5A, are specifically designed to adsorb CO and CO₂. These sieves capture these impurities, ensuring that only high-quality hydrogen is produced.

How do molecular sieves contribute to green energy initiatives?

Molecular sieves play a critical role in producing clean hydrogen for green energy applications. By ensuring high hydrogen purity, they support eco-friendly technologies, like fuel cells, which contribute to reducing carbon emissions.

What are the typical industrial applications of molecular sieves in hydrogen purification?

Molecular sieves are widely used in petrochemical industries, hydrogen production facilities, and fuel cell technology. Their primary role is to purify hydrogen by removing moisture and impurities, ensuring reliable and efficient operations.

How do molecular sieves improve hydrogen quality?

Molecular sieves enhance hydrogen quality by removing impurities like moisture, CO, and CO₂. This ensures the hydrogen is of high purity, which is essential for sensitive applications such as fuel cells and industrial processes.

Which molecular sieve types are best suited for hydrogen purification?

Types such as 5A and 13X are commonly used for hydrogen purification. 13X molecular sieves are particularly effective due to their larger pore size, which can capture a wide range of impurities.

How does CO₂ adsorption work in molecular sieves?

Molecular sieves trap CO₂ molecules within their pores through selective adsorption. This process allows them to remove CO₂ from hydrogen streams, ensuring that only high-purity hydrogen is produced.

Are molecular sieves effective in hydrogen purification for petrochemical applications?

Yes, in the petrochemical industry, molecular sieves are critical for purifying hydrogen used in refining and processing. They remove impurities that can interfere with catalytic processes and reduce product quality.

How do molecular sieves contribute to fuel cell efficiency?

By removing impurities from hydrogen, molecular sieves provide cleaner fuel for fuel cells. This reduces the risk of catalyst poisoning, enhances energy output, and extends the cell’s operational life.

What makes molecular sieves an ideal choice for hydrogen purification?

Their high adsorption capacity, selectivity, and durability make molecular sieves ideal for hydrogen purification. They provide consistent performance, even under varying industrial conditions, ensuring reliable hydrogen quality.

How are molecular sieves regenerated in hydrogen purification systems?

Molecular sieves are typically regenerated through heating or pressure swing methods. This process removes the adsorbed impurities, allowing the sieve to be reused multiple times in purification cycles.

Do molecular sieves help in reducing environmental impact?

Yes, by producing cleaner hydrogen, molecular sieves support eco-friendly technologies that reduce carbon emissions. They enable efficient fuel cell operations and sustainable hydrogen production, contributing to green energy goals.

How does hydrogen purity impact petrochemical refining processes?

High-purity hydrogen is essential in refining to prevent unwanted chemical reactions and to improve product quality. Molecular sieves ensure that hydrogen used in these processes meets stringent purity standards.

Can molecular sieves handle high pressures in hydrogen purification?

Yes, molecular sieves are designed to withstand high-pressure environments typically found in industrial hydrogen purification systems, making them suitable for demanding applications.

What is the role of molecular sieves in hydrogen quality control?

Molecular sieves ensure consistent hydrogen quality by removing trace impurities. This quality control is crucial for applications where purity directly impacts performance, such as in fuel cells and medical-grade hydrogen.

How does impurity removal with molecular sieves support hydrogen fuel efficiency?

By eliminating contaminants, molecular sieves ensure that hydrogen burns more cleanly and efficiently, maximizing energy output and reducing waste in hydrogen-fueled applications.

Are molecular sieves suitable for large-scale hydrogen purification operations?

Yes, molecular sieves are highly effective in large-scale operations. Their robust adsorption capacity and regenerative capabilities make them suitable for extensive use in hydrogen purification plants.

Conclusion: Choosing the Right Molecular Sieve for Hydrogen Purification

When selecting a molecular sieve for hydrogen purification, 5A and 13X offer complementary strengths that can be leveraged depending on the specific purification requirements. 5A molecular sieves are ideal for precision-focused purification that targets smaller contaminants like CO and water, which are critical in fuel cell and high-purity hydrogen applications. 13X molecular sieves, with their larger pore size, are better suited for processes needing broader adsorption, effectively handling CO₂ and other larger impurities in hydrogen production. A combination of 5A and 13X in multi-stage purification systems can provide a comprehensive solution, meeting the highest hydrogen purity standards for industrial and green energy applications.

To explore our full range of molecular sieve options tailored for hydrogen purification, visit Molecular Sieve. For further insights, our cornerstone article, A Comprehensive Guide to Molecular Sieves, offers additional guidance on the applications and selection of molecular sieves.

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้