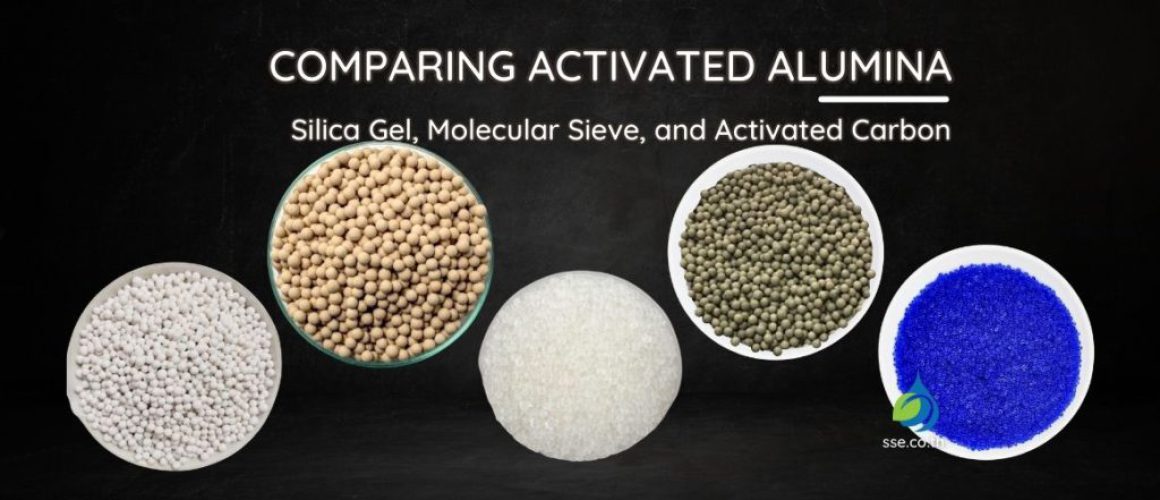

Comparing Activated Alumina with Other Desiccants: Silica Gel, Molecular Sieve, and Activated Carbon

| Key Takeaway | Description |

|---|---|

| Versatility | Activated Alumina is versatile, suitable for air drying, gas purification, and water treatment. |

| Adsorption Capacity | Molecular Sieves have the highest adsorption capacity, followed by Activated Alumina. |

| Thermal Stability | Activated Alumina excels in thermal stability, making it ideal for high-temperature uses. |

| Cost Consideration | Silica Gel is cost-effective but has lower efficiency, whereas Molecular Sieves are high-cost. |

| Application Suitability | The choice of desiccant depends on industry-specific needs like adsorption efficiency and cost. |

Table of Contents

“Understanding their properties and performance characteristics can help you select the most appropriate desiccant for your specific needs.”

Introduction

Desiccants play a crucial role in many industrial processes by controlling moisture levels to ensure product quality, performance, and longevity. Among the various desiccants available in the market, activated alumina desiccant, silica gel, molecular sieves, and activated carbon are the most common. In this article, we will discuss the properties, advantages, and disadvantages of these desiccants and provide a comparison to help you make an informed decision for your specific application.

Common Applications by Industry:

| Industry | Recommended Desiccant | Reason |

|---|---|---|

| Electronics | Silica Gel | Non-toxic, low dust formation |

| Water Treatment | Activated Alumina | Adsorbs contaminants |

| Air Purification | Activated Carbon | Odor control |

| Gas Processing | Molecular Sieve | Specific molecular adsorption |

Activated Alumina Desiccant

Properties and Advantages

Activated alumina, a porous form of aluminum oxide, is a highly effective desiccant known for its large surface area and strong affinity for water molecules. Its high adsorption capacity and excellent thermal stability make it suitable for various applications, including air drying, gas purification, and water treatment. Additionally, activated alumina can adsorb other contaminants such as sulfur, chlorine, and arsenic, providing added benefits for certain industries.

Disadvantages and Limitations

Despite its many advantages, activated alumina desiccant also has some limitations, including sensitivity to high humidity and potential fluoride leaching. Under extremely high humidity conditions, activated alumina may lose its effectiveness, and its adsorption capacity may decrease. Furthermore, when used for water treatment, activated alumina can sometimes leach fluoride, which can lead to increased fluoride levels in treated water. To overcome these limitations, proper regeneration and maintenance of activated alumina are crucial.

Humidity Effect on Desiccants:

| Desiccant Type | Low Humidity Efficiency | High Humidity Efficiency |

|---|---|---|

| Activated Alumina | High | Moderate |

| Silica Gel | Moderate | Low |

| Molecular Sieve | Very High | High |

| Activated Carbon | Low | Low |

Silica Gel Desiccant

Properties and Advantages

Silica gel, a porous form of silicon dioxide, is a widely used desiccant due to its non-toxic nature, high adsorption capacity, and low cost. Its inertness and compatibility with various materials make it suitable for diverse applications, such as electronics, pharmaceuticals, and food packaging. Silica gel desiccant can effectively adsorb moisture at a wide range of temperatures and relative humidity levels, providing consistent performance.

Disadvantages and Limitations

While silica gel offers many benefits, its limitations include lower thermal stability and mechanical strength compared to other desiccants. At elevated temperatures, silica gel may lose its adsorption capacity, making it less effective in high-temperature applications. Additionally, silica gel can break down into fine particles over time, which may cause dust formation and clogging in some systems. Proper handling and maintenance can help minimize these issues.

Molecular Sieve Desiccant

Properties and Advantages

Molecular sieves, comprised of crystalline aluminosilicates with uniform pore sizes, are known for their excellent moisture adsorption capacity, particularly at low relative humidity levels. Their selective adsorption properties enable them to target specific molecules, making them ideal for gas separation, purification, and drying applications. Molecular sieves offer high thermal stability and mechanical strength, allowing them to maintain their performance under various operating conditions.

Disadvantages and Limitations

Despite their high efficiency, molecular sieves have some drawbacks, such as higher cost and potential for dust formation during handling and use. Due to their complex manufacturing process, molecular sieves tend to be more expensive than other desiccants. Furthermore, the crystalline structure of molecular sieves can generate dust during handling, which may require additional filtration or dust control measures.

Cost vs Efficiency Comparison:

| Desiccant | Cost | Efficiency (Low, Medium, High) |

|---|---|---|

| Activated Alumina | Medium | High |

| Silica Gel | Low | Medium |

| Molecular Sieve | High | Very High |

| Activated Carbon | Low | Medium |

Activated Carbon Desiccant

Properties and Advantages

Activated carbon, derived from carbonaceous materials, is a versatile desiccant known for its high porosity, large surface area, and excellent adsorption capacity for various gases and odors. Its ability to adsorb a wide range of organic and inorganic contaminants makes it suitable for applications in air purification, water treatment, and odor control. Activated carbon is also environmentally friendly, as it can be derived from renewable sources and regenerated multiple times.

Disadvantages and Limitations

While activated carbon offers many advantages, it also has some limitations, including lower moisture adsorption capacity compared to other desiccants, sensitivity to high humidity, and potential for dust generation. Activated carbon is more effective at adsorbing gases and odors than moisture, making it less suitable for some high-moisture applications. Moreover, its performance may decrease under high humidity conditions, and dust generation may occur during handling and use, requiring additional filtration or dust control measures.

Comparison and Application Recommendations

Properties Comparison Table:

| Desiccant Type | Adsorption Capacity | Thermal Stability | Cost | Main Applications |

|---|---|---|---|---|

| Activated Alumina | High | Excellent | Moderate | Air drying, water treatment |

| Silica Gel | Moderate | Moderate | Low | Food packaging, electronics |

| Molecular Sieve | Very High | High | High | Gas separation, drying gases |

| Activated Carbon | Moderate | Low | Low | Air purification, odor control |

When choosing a desiccant for a specific application, it is essential to consider factors such as adsorption capacity, thermal stability, mechanical strength, cost, and compatibility with the process and materials. Activated alumina is an excellent choice for air drying, gas purification, and water treatment applications, while silica gel is more suitable for low-temperature and low-humidity applications, such as electronics, pharmaceuticals, and food packaging.

Molecular sieves are ideal for gas separation and purification processes, especially when targeting specific molecules. In contrast, activated carbon is best suited for air purification, water treatment, and odor control applications, where adsorption of gases and odors is more critical than moisture control.

Regeneration Requirements:

| Desiccant Type | Regeneration Temperature | Frequency of Regeneration |

|---|---|---|

| Activated Alumina | 150-200°C | High |

| Silica Gel | 100-120°C | Moderate |

| Molecular Sieve | 200-300°C | Low |

| Activated Carbon | 120-150°C | High |

Conclusion: Selecting the Right Desiccant for Your Application

In conclusion, activated alumina, silica gel, molecular sieves, and activated carbon each offer unique advantages and limitations, making them suitable for different applications. Understanding their properties and performance characteristics can help you select the most appropriate desiccant for your specific needs. By choosing the right desiccant and implementing proper handling, maintenance, and regeneration practices, you can optimize the performance and lifetime of your moisture control systems, ensuring the highest level of protection for your products and processes.

Frequently Asked Questions

What is activated alumina desiccant?

Activated alumina desiccant is a highly porous, granular form of aluminum oxide that effectively removes moisture, impurities, and contaminants from gases and liquids.

Is alumina better than silica gel?

Alumina and silica gel have different properties and are better suited for different applications. Alumina has higher thermal stability and adsorption capacity, making it more suitable for high-temperature and high-humidity applications. Silica gel is more effective in low-temperature and low-humidity applications, such as electronics and pharmaceutical packaging.

What is the difference between activated alumina and silica gel?

Activated alumina is made from aluminum oxide, while silica gel is made from silicon dioxide. Activated alumina has higher thermal stability, adsorption capacity, and mechanical strength compared to silica gel.

Is activated alumina an absorbent?

Yes, activated alumina is an effective absorbent used for adsorbing moisture and impurities from gases and liquids.

Why is alumina better than silica?

Alumina is better than silica in applications that require high thermal stability, adsorption capacity, and mechanical strength. Alumina is also more effective in high-temperature and high-humidity environments.

Why use alumina instead of silica?

Alumina is used instead of silica when higher thermal stability, adsorption capacity, and mechanical strength are required. It is also more effective in high-temperature and high-humidity applications.

What is the most efficient desiccant?

The most efficient desiccant depends on the specific application and the required properties. Activated alumina, silica gel, molecular sieves, and activated carbon are all effective desiccants with unique advantages and limitations.

What are the disadvantages of activated alumina?

Some disadvantages of activated alumina include higher cost compared to other desiccants, the need for regular regeneration, and potential for dust generation during handling and use.

What are the advantages of activated alumina?

Advantages of activated alumina include high adsorption capacity, thermal stability, mechanical strength, and effectiveness in high-temperature and high-humidity applications.

How long does activated alumina last?

The lifespan of activated alumina depends on the operating conditions, such as temperature, humidity, and the presence of impurities. With proper maintenance and regeneration, activated alumina can last for several years.

Is alumina a silica?

No, alumina is not a silica. Alumina is aluminum oxide (Al2O3), while silica is silicon dioxide (SiO2). Both are oxide materials but have different chemical compositions and properties.

Which is a powerful eco-friendly desiccant?

Activated alumina, silica gel, molecular sieves, and activated carbon are all eco-friendly desiccants, as they can be regenerated and reused multiple times. The most powerful desiccant for a specific application depends on factors such as temperature, humidity, and the desired properties.

What are the three types of desiccant?

Three common types of desiccants are activated alumina, silica gel, and molecular sieves. Other desiccants include activated carbon, calcium chloride, and clay.

Conclusion and Next Steps

Selecting the right desiccant is essential for efficient moisture control and optimal results in your specific industry. If you’re intrigued by the versatility of desiccants and want to explore further, dive into our article on The Versatility of 13X Molecular Sieves to understand their wide-ranging applications. For a detailed look at different molecular sieves, our Comprehensive Guide to Molecular Sieves can provide valuable insights.

Activated Alumina remains a versatile solution for air drying, water purification, and gas treatment. Learn more about The Regeneration Process of Activated Alumina: Techniques and Best Practices to maximize its efficiency or explore our Comprehensive Guide to Activated Alumina for in-depth information. If safety is a concern, make sure to check out our Safety Considerations and Handling Guidelines for Activated Alumina.

For air purification needs, The Benefits of Activated Carbon for Air Purification is a great resource to understand how activated carbon can be effectively utilized or our Comprehensive Guide to Activated Carbon 2024. If you’re interested in a powerful, specialized desiccant, The Power of JLOX Molecular Sieves provides details on this effective solution.

If you still have questions about which desiccant best suits your needs, don’t hesitate to explore our comprehensive resources or contact our team for personalized guidance. We’re here to support you in choosing the best moisture control solution for your applications.

Activated Alumina on ScienceDirect

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้