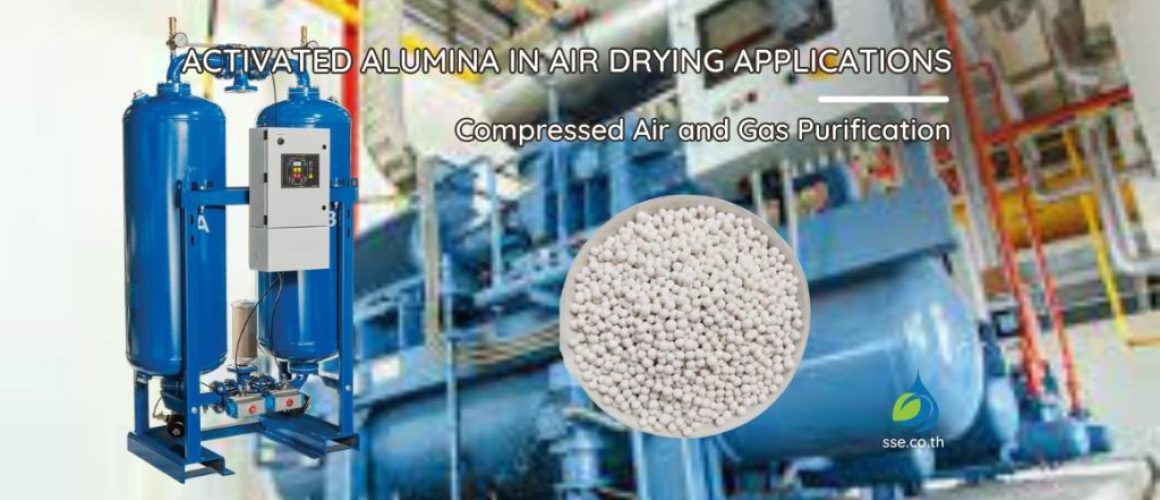

Activated Alumina in Air Drying Applications: Compressed Air and Gas Purification

| Key Aspect | Details |

|---|---|

| Primary Use | Moisture removal from compressed air and gas streams to ensure dry, reliable air supply |

| Industries Served | Industrial manufacturing, pneumatic systems, chemical processing, natural gas drying |

| Main Benefits | High adsorption capacity, regenerable, prevents equipment corrosion and improves system efficiency |

| Applications | Compressed air drying, natural gas processing, moisture control in sensitive production |

| Dew Point Achievement | Helps achieve ultra-low dew points, essential for high-purity applications |

| Performance Factors | Operates effectively across a wide temperature range, offering stability and efficiency |

Table of Content

Introduction to Activated Alumina Air Drying

Activated alumina is a versatile and highly effective desiccant used in various air drying applications, including compressed air and gas purification. In this article, we will delve into the role of activated alumina in air drying, its applications in compressed air drying and gas purification, and best practices for using activated alumina in these processes.

How Activated Alumina Air Drying Plays a Crucial Role

What is activated alumina?

Activated alumina is a porous, granular form of aluminum oxide that exhibits high surface area and excellent adsorption properties. Due to its unique physical and chemical properties, activated alumina has become a popular choice for various industrial applications, especially in air drying and gas purification processes.

Why is activated alumina used in air drying applications?

Activated alumina’s high surface area and strong affinity for moisture make it ideal for removing water vapor from compressed air and gas streams. Its ability to adsorb large quantities of moisture and resist thermal shock makes it an attractive desiccant material for a wide range of industries.

Compressed Air Drying with Activated Alumina

Importance of compressed air drying

Proper drying of compressed air is essential for protecting equipment and ensuring process efficiency. Moisture in compressed air can lead to corrosion, equipment failure, and reduced product quality. As a result, removing water vapor from compressed air systems is crucial for maintaining optimal performance and prolonging the life of equipment.

Types of air dryers using activated alumina

Activated alumina is commonly used in desiccant air dryers such as heatless, heated, and blower purge dryers. These dryers rely on the adsorption properties of activated alumina to remove moisture from the air stream, achieving low pressure dew points and ensuring dry, high-quality compressed air.

Benefits of using activated alumina in compressed air drying

Activated alumina provides a reliable and cost-effective solution for achieving low pressure dew points in compressed air systems. Its high adsorption capacity and resistance to thermal shock make it an ideal choice for compressed air drying applications, offering the following benefits:

- Efficient moisture removal: Activated alumina can adsorb up to 20% of its weight in water, ensuring efficient and thorough drying of compressed air.

- Long service life: With proper regeneration and maintenance, activated alumina can provide years of reliable service in compressed air drying applications.

- Wide operating temperature range: Activated alumina can function effectively at temperatures ranging from -40°C to 200°C, making it suitable for various industrial environments.

Gas Purification with Activated Alumina

Common gases purified using activated alumina

Activated alumina is used in the purification of gases such as natural gas, hydrogen, oxygen, and nitrogen. Its excellent adsorption properties enable it to effectively remove moisture, contaminants, and other impurities from gas streams, ensuring high-quality purified gases for industrial applications.

Moisture removal and pressure dew point control

Activated alumina effectively removes moisture from gas streams, helping to achieve desired pressure dew points and prevent corrosion or freezing. By controlling the pressure dew point of gas streams, activated alumina can protect equipment, prevent process disruptions, and ensure the production of high-quality, dry gases.

Benefits of using activated alumina for gas purification

Activated alumina’s high adsorption capacity and resistance to thermal shock make it an ideal choice for gas purification applications. Some key benefits of using activated alumina in gas purification processes include:

- High adsorption capacity: Activated alumina’s large surface area allows it to effectively adsorb a wide range of impurities from gas streams.

- Regenerable: Activated alumina can be regenerated and reused multiple times, reducing operating costs and minimizing waste.

- Versatility: Activated alumina is suitable for various gas purification applications, including moisture removal, hydrocarbon removal, and the elimination of other impurities.

- Chemical stability: Activated alumina is chemically stable and non-reactive, ensuring the integrity of the purified gas stream and preventing contamination.

- Wide operating temperature range: Activated alumina’s ability to function effectively at temperatures ranging from -40°C to 200°C makes it suitable for a variety of industrial environments.

Best Practices for Using Activated Alumina in Air Drying and Gas Purification

Proper sizing and selection of activated alumina

To ensure optimal performance, it is crucial to select the appropriate size and grade of activated alumina for a specific air drying or gas purification application. Factors such as the required pressure dew point, gas flow rate, and operating temperature should be considered when choosing the right activated alumina product.

Regular maintenance and regeneration

To maximize the service life and effectiveness of activated alumina, regular maintenance and regeneration are essential. Regeneration involves heating the activated alumina to remove the adsorbed moisture and impurities, allowing it to be reused. Proper regeneration techniques and schedules should be followed to ensure the continued performance of activated alumina in air drying and gas purification processes.

Monitoring and replacement

Periodically monitoring the performance of activated alumina in air drying and gas purification systems is crucial for identifying any issues and ensuring optimal results. When activated alumina’s adsorption capacity is exhausted or its performance begins to decline, timely replacement is necessary to maintain system efficiency and protect equipment.

FAQ Section

How does activated alumina adsorb moisture in air drying applications?

Activated alumina adsorbs moisture through a process called adsorption, where water molecules adhere to its highly porous surface. The large surface area of activated alumina allows it to adsorb significant amounts of moisture from compressed air and gas streams.

Is activated alumina safe for use in air drying and gas purification applications?

Yes, activated alumina is a safe and chemically stable material for use in air drying and gas purification applications. It is non-toxic and non-reactive, ensuring that it will not contaminate the compressed air or gas stream.

Can activated alumina be regenerated and reused?

Yes, activated alumina can be regenerated by heating it to remove adsorbed moisture and impurities. Proper regeneration techniques and schedules should be followed to ensure the continued performance of activated alumina in air drying and gas purification processes.

What factors should be considered when selecting activated alumina for air drying and gas purification applications?

Factors such as the required pressure dew point, gas flow rate, and operating temperature should be considered when selecting the appropriate size and grade of activated alumina for a specific air drying or gas purification application.

What is the use of air drying?

Air drying is used to remove moisture from various materials, including compressed air and gas streams, food products, and textiles. It helps prevent corrosion, microbial growth, and product spoilage.

What is the advantage of air drying?

Air drying offers several advantages, such as energy efficiency, cost-effectiveness, and the preservation of product quality, particularly in food and textile industries.

What is air drying and what is the benefit?

Air drying is a process that removes moisture from materials by exposing them to ambient or heated air. The benefits of air drying include energy efficiency, cost-effectiveness, and preservation of product quality.

What are the disadvantages of air drying?

Disadvantages of air drying include longer drying times, potential exposure to contaminants, and the risk of uneven drying, which can result in reduced product quality.

Conclusion: Activated Alumina’s Vital Role in Air Drying and Gas Purification

Activated alumina’s exceptional adsorption properties, chemical stability, and versatility make it an ideal choice for air drying and gas purification applications. By selecting the right activated alumina product, maintaining and regenerating it properly, and monitoring its performance, industries can rely on this efficient desiccant to provide dry, high-quality compressed air and purified gases for various applications.

For those looking to explore the diverse industrial applications of this powerful adsorbent, Activated Alumina Applications: Industrial Uses in Drying, Purification, and Catalysis provides an in-depth look at how activated alumina supports processes like moisture control, gas purification, and catalytic reactions across various industries. This guide outlines its indispensable role in sectors from environmental management to petrochemical refining, highlighting its versatility and efficiency in enhancing industrial performance. See also A Comprehensive Guide to Activated Alumina or Studies in Surface Science and Catalysis