The Impact of Humidity on Various Industries and How Desiccants Can Help

Table of Contents

Introduction

Humidity, often overlooked, plays a crucial role in various industries, affecting product quality, safety, and longevity. Understanding the impact of humidity and how to control it is essential for maintaining operational efficiency and product integrity.

Understanding Humidity

A. Definition of Humidity

Humidity refers to the amount of water vapor present in the air, a factor that can significantly impact various industries. It’s a pervasive natural phenomenon that can cause significant problems if not properly managed.

B. Relative Humidity and Absolute Humidity

Understanding the impact of humidity on various industries requires a grasp of two key terms: relative humidity and absolute humidity.

Relative humidity, expressed as a percentage, is the amount of moisture present in the air compared to the maximum amount the air could hold at a given temperature. For instance, a relative humidity of 50% means the air is holding half the moisture it could potentially hold at that temperature. This is a crucial factor as it directly influences how we perceive the humidity in our environment. High relative humidity often makes the environment feel warmer and more uncomfortable, which can affect both human comfort and the performance of certain industrial processes.

Absolute humidity, on the other hand, is the total amount of water vapor present in a particular volume of air, regardless of temperature. It is usually expressed in grams per cubic meter. This measure is particularly important in industries where the concentration of water vapor in the air can affect product quality or the efficiency of processes. For example, in the pharmaceutical industry, a high absolute humidity can cause hygroscopic drugs to absorb moisture, leading to clumping and degradation.

Both relative and absolute humidity can have varying effects on different materials and processes. For instance, wood can expand or contract depending on the relative humidity, affecting the quality of wooden furniture or musical instruments. In the electronics industry, both high relative and absolute humidity can lead to condensation, causing short circuits and corrosion in electronic devices.

The Impact of Humidity on Various Industries

A. Food and Beverage Industry

In the food and beverage industry, high humidity can lead to the growth of mold and bacteria, spoilage, and a decrease in product shelf life. For instance, in bakeries, excess moisture can cause bread to become soggy and encourage mold growth. This not only affects the quality and taste of the bread but also its shelf life, leading to increased waste and reduced profits.

Similarly, in the brewing industry, humidity can affect the fermentation process, altering the taste and quality of the beer. The yeast used in brewing is sensitive to environmental conditions, and changes in humidity can lead to off-flavors and inconsistent batches.

In both these scenarios, Silica Gel and Activated Clay can be valuable tools in managing these issues. By absorbing excess moisture, these desiccants can help maintain optimal humidity levels, ensuring the quality and longevity of food and beverage products.

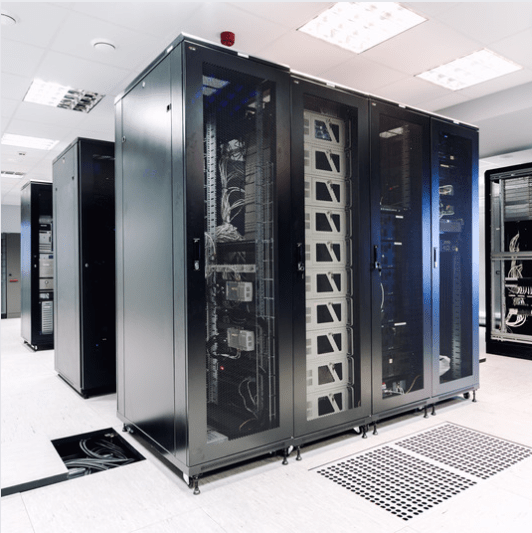

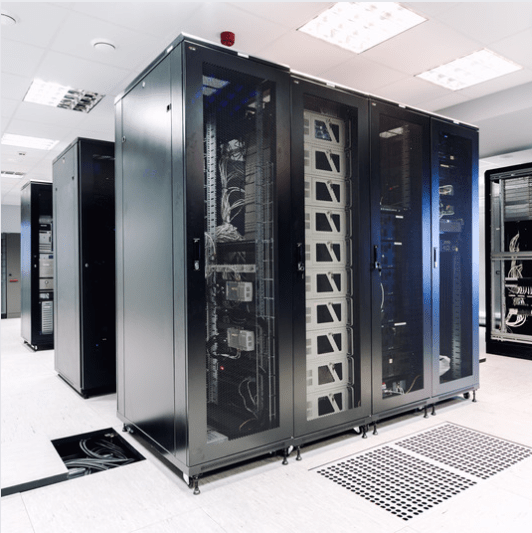

B. Electronics and IT Industry

The electronics and IT industry is another sector significantly affected by humidity. High humidity can lead to condensation, causing short circuits and corrosion in electronic devices, leading to system failures. This is particularly problematic for data centers, where a large number of electronic components are stored in a confined space, making effective humidity control crucial.

On the other hand, low humidity can increase static electricity, which can also damage sensitive electronic components. Static electricity can cause components to fail prematurely, leading to costly repairs and downtime.

In this industry, Activated Alumina, Activated Clay, and Silica Gel are often used to control humidity levels. These desiccants are effective in absorbing moisture and maintaining optimal humidity levels.

C. Pharmaceutical Industry

In the pharmaceutical industry, humidity control is crucial. Excessive humidity can affect the efficacy of drugs, lead to bacterial growth, and alter the physical properties of tablets and capsules. For example, high humidity can cause tablets to stick together or alter their dissolution rate, affecting how the drug is released into the body.

Hygroscopic drugs, which absorb moisture from the environment, can also be affected by high humidity. These drugs can clump together, making them difficult to administer and reducing their effectiveness.

In these situations, a Molecular Sieve and Activated Clayare common solutions for these challenges. These desiccants effectively control humidity and ensure the quality and efficacy of pharmaceutical products.

D. Shipping and Storage

During shipping and storage, goods are often exposed to varying levels of humidity, which can lead to rust, corrosion, mold, and warping. This is particularly problematic for goods like furniture, artwork, clothing, and metal products. For example, high humidity can cause wooden furniture to warp and metal products to rust, reducing their value and lifespan.

Moreover, the impact of humidity is not limited to non-perishable goods. In the case of food exports such as rice, coffee and tapioca, humidity control is crucial. These products are hygroscopic, meaning they can absorb moisture from the environment. In a high humidity environment, rice and tapioca can absorb excess moisture, leading to spoilage, mold growth, and a decrease in quality. This not only affects the taste and texture of these products but can also lead to significant economic losses due to rejected shipments and decreased consumer satisfaction.

In these situations, a Container Desiccant can protect goods from humidity-related damage during transit. These desiccants are designed to absorb large amounts of moisture, preventing condensation and ensuring that goods arrive at their destination in optimal condition.

Humidity and Employee Productivity

Humidity doesn’t just impact the products and processes in various industries; it also significantly affects the comfort and productivity of employees in the workplace. The ideal humidity range for a comfortable work environment is between 30% and 50%. When humidity levels exceed this range, it can lead to discomfort among employees, including symptoms like excessive sweating and fatigue. On the other hand, low humidity can cause dry skin and eyes, leading to discomfort and decreased productivity. Therefore, maintaining the right humidity levels is crucial not just for product quality but also for ensuring a healthy and productive work environment.

Humidity Measurement and Control

Regularly monitoring and controlling humidity levels is a critical aspect of managing its impact on different industries. Various types of equipment, such as humidity meters and dehumidifiers, are used to measure and control humidity. Humidity meters provide accurate readings of humidity levels, helping businesses monitor and maintain the ideal conditions. On the other hand, dehumidifiers are used to reduce excess moisture in the air, helping to keep humidity levels within the desired range. By effectively measuring and controlling humidity, businesses can mitigate its negative effects and ensure optimal conditions for their operations.

Safety Considerations

Safety is another crucial aspect to consider when it comes to humidity in the workplace. High humidity levels can lead to the growth of mold and bacteria, posing potential health risks to employees. Moreover, high humidity can also lead to condensation, causing slip-and-fall hazards. Therefore, maintaining a safe and comfortable work environment involves managing humidity levels effectively to prevent these potential risks. By doing so, businesses can ensure the well-being of their employees while also maintaining the quality and integrity of their products and processes.

The Role of Desiccants in Humidity Control

A. What are Desiccants?

Desiccants are hygroscopic substances that absorb moisture from their surroundings, helping to control humidity levels. These materials are crucial in various industries where they protect goods, materials, and processes from the damaging effects of humidity. They are often used in packaging to prevent moisture-induced damage during shipping and storage, and in manufacturing processes where humidity control is critical for maintaining product quality and consistency.

B. Types of Desiccants

There are several types of desiccants used across industries, each with unique properties and applications, making them suitable for different situations.

- Silica Gel: This is perhaps the most commonly recognized desiccant. It is a form of silicon dioxide and has a very high moisture-absorbing capacity, making it ideal for a wide range of applications, from food and pharmaceutical packaging to electronics.

- Activated Alumina: Made from aluminum oxide, activated alumina is highly porous and capable of absorbing moisture in high-temperature environments. It is often used in the purification of gases and liquids and in the drying of compressed air.

- Activated Clay: Also known as bentonite clay, activated clay is a natural, non-toxic material that is used as a desiccant due to its ability to absorb moisture. It is commonly used in industrial applications, including the drying of air, gases, and liquids.

- Molecular Sieves: These are synthetic zeolites with a very uniform pore size. This allows them to selectively absorb water molecules while excluding larger molecules, making them highly effective as desiccants. They are often used in the petrochemical industry and for the dehydration of gases and liquids.

- Container Desiccant: These are specially designed desiccants for use in shipping containers. They are typically hung or placed within the container and work to absorb the excess moisture during transit, protecting the goods from humidity-related damage such as mold, corrosion, and warping. Container desiccants are often made from materials like calcium chloride, which can absorb up to several times its own weight in water, making them highly effective for this purpose.

C. How Desiccants Work

Desiccants work by absorbing moisture from the air, effectively reducing the relative humidity in a given environment and reducing the impact of humidity. This process, known as adsorption, involves the water molecules adhering to the surface of the desiccant material. By reducing the humidity, desiccants help to protect goods and processes from the damaging effects of humidity, such as corrosion, mold growth, and product degradation, ensuring their quality and longevity.

The effectiveness of a desiccant will depend on several factors, including the specific type of desiccant used, the relative humidity, and the temperature of the environment. Therefore, choosing the right desiccant for a specific application is crucial for optimal performance.

Case Studies: Desiccants in Action

Food and Beverage Industry

In the food and beverage industry, high humidity can be a real challenge. It can lead to the growth of mold and bacteria, spoilage, and a decrease in product shelf life. For instance, in bakeries, excess moisture can cause bread to become soggy and encourage mold growth. This not only affects the quality and taste of the bread but also its shelf life, leading to increased waste and reduced profits. By effectively absorbing moisture, silica gel can help to extend the shelf life of food products and maintain their quality.

Similarly, in the brewing industry, humidity can affect the fermentation process, altering the taste and quality of the beer. The yeast used in brewing is sensitive to environmental conditions, and changes in humidity can lead to off-flavors and inconsistent batches.

In both these scenarios, Silica Gel and Activated Clay can be valuable tools in managing these issues. By absorbing excess moisture, these desiccants can help maintain optimal humidity levels, ensuring the quality and longevity of food and beverage products.

Electronics and IT Industry

The electronics and IT industry is another sector suffering significantly from the impact of humidity. High humidity can lead to condensation, causing short circuits and corrosion in electronic devices, leading to system failures. This is particularly problematic for data centers, where a large number of electronic components are stored in a confined space, making effective humidity control crucial.

On the other hand, low humidity can increase static electricity, which can also damage sensitive electronic components. Static electricity can cause components to fail prematurely, leading to costly repairs and downtime.

In this industry, Activated Alumina, Activated Clay, and Silica Gel are often used to control humidity levels. These desiccants are effective in absorbing moisture and maintaining optimal humidity levels.

Pharmaceutical Industry

In the pharmaceutical industry, humidity control is crucial. Excessive humidity can affect the efficacy of drugs, lead to bacterial growth, and alter the physical properties of tablets and capsules. For example, high humidity can cause tablets to stick together or alter their dissolution rate, affecting how the drug is released into the body.

Hygroscopic drugs, which absorb moisture from the environment, can also be affected by high humidity. These drugs can clump together, making them difficult to administer and reducing their effectiveness.

In these situations, a Molecular Sieve and Activated Clay are common solutions for these challenges. These desiccants effectively control humidity and ensure the quality and efficacy of pharmaceutical products.

Shipping and Storage

During shipping and storage, goods are often exposed to varying levels of humidity, which can lead to rust, corrosion, mold, and warping. This is particularly problematic for goods like furniture, artwork, clothing, and metal products. For example, high humidity can cause wooden furniture to warp and metal products to rust, reducing their value and lifespan.

In these situations, a Container Desiccant can protect goods from humidity-related damage during transit. These desiccants are designed to absorb large amounts of moisture, preventing condensation and ensuring that goods arrive at their destination in optimal condition.

Navigating Humidity: A Key to Industry Success

While humidity can pose significant challenges across various industries, the use of desiccants can effectively mitigate these problems. By controlling humidity levels, desiccants ensure the quality and longevity of products, protect sensitive equipment, and maintain the efficacy of pharmaceuticals, thereby reducing the impact of humidity. As such, understanding and managing humidity is key to success in any industry.

Frequently Asked Questions

What is the importance of humidity in industries?

Humidity plays a crucial role in various industries, affecting product quality, safety, and longevity. It can lead to the growth of mold and bacteria, spoilage, and a decrease in product shelf life. It can also cause condensation, leading to corrosion in electronic devices and system failures.

What is the impact of humidity?

The impact of humidity can be seen in various ways, from the growth of mold and bacteria in food products to the corrosion and short-circuiting of electronic devices. It can also affect the physical properties of pharmaceutical products and cause damage during shipping and storage.

What are the factors that affect humidity?

Several factors can affect humidity, including temperature, air pressure, and the amount of water vapor in the air. Changes in any of these factors can lead to changes in humidity levels.

How does humidity affect the workplace?

Humidity can affect the workplace in several ways. High humidity can lead to discomfort and decreased productivity among employees. It can also cause damage to office equipment and furniture.

How does humidity affect product quality?

Humidity can significantly affect product quality. In the food and beverage industry, it can lead to the growth of mold and bacteria, spoilage, and a decrease in product shelf life. In the electronics industry, it can cause condensation, leading to corrosion and system failures.

How does high humidity impact performance?

High humidity can impact performance in several ways. In the workplace, it can lead to discomfort and decreased productivity among employees. In industries such as food and beverage, electronics, and pharmaceuticals, it can affect product quality and safety.

How does humidity affect material?

Humidity can affect materials in several ways. It can cause metal to rust, wood to warp, and paper to become damp and brittle. It can also affect the physical properties of pharmaceutical products and the quality of food products.

Does humidity affect technology?

Yes, humidity can significantly affect technology. High humidity can lead to condensation, causing short circuits and corrosion in electronic devices, leading to system failures. On the other hand, low humidity can increase static electricity, which can also damage sensitive electronic components.

How does humidity affect machines?

Humidity can affect machines in several ways. It can cause metal parts to rust and electrical components to short circuit. It can also lead to the growth of mold and bacteria, which can affect the functioning of the machine.

Is 70% humidity bad for electronics?

Yes, 70% humidity is generally considered too high for electronics. High humidity can lead to condensation, which can cause short circuits and corrosion in electronic devices, leading to system failures.

How do you reduce humidity?

Humidity can be reduced by improving ventilation, using air conditioners and dehumidifiers, and using desiccants. It’s also important to regularly monitor humidity levels to ensure they stay within the ideal range.

What is the best humidity level?

The ideal humidity level depends on the specific needs of the environment. However, for most indoor environments, a humidity level of between 30% and 50% is considered ideal.

Can humidity cause damage?

Yes, humidity can cause significant damage. It can lead to the growth of mold and bacteria, spoilage of food products, corrosion and short-circuiting of electronic devices, and damage to goods during shipping and storage.

What happens when humidity is high?

When humidity is high, it can lead to discomfort and decreased productivity in the workplace. It can also cause damage to goods and equipment, including the growth of mold and bacteria, spoilage of food products, and corrosion of electronic devices.

What happens if humidity is low?

If humidity is too low, it can cause discomfort, such as dry skin and eyes. In the workplace, it can lead to static electricity, which can damage electronic equipment. In industries such as food and beverage and pharmaceuticals, it can affect the quality and safety of products.

What is worse high or low humidity?

Both high and low humidity can cause problems, depending on the specific needs of the environment. High humidity can lead to mold growth and corrosion, while low humidity can cause discomfort and static electricity. It’s important to maintain a balanced humidity level to prevent these issues.

What is the problem with 100% humidity?

At 100% humidity, the air is saturated with water vapor and cannot hold any more. This can lead to condensation and a high risk of mold growth and corrosion. It can also cause discomfort and decreased productivity in the workplace.

What makes humidity worse?

Factors such as high temperatures, poor ventilation, and the presence of water sources can make humidity worse. These factors can increase the amount of water vapor in the air, leading to higher humidity levels.

How does humidity affect measurement?

Humidity can affect measurement in several ways. For example, it can cause metal measuring instruments to rust, affecting their accuracy. It can also affect the weight of items, as high humidity can cause some materials to absorb moisture from the air.

What is the range of humidity in industry?

The ideal range of humidity in industry depends on the specific needs of the industry. However, for most industries, a humidity level of between 30% and 50% is considered ideal.

Call to Action

If you’re facing challenges with humidity in your industry, consider exploring our range of high-quality desiccants at SSE. Our products are designed to effectively control humidity, ensuring the quality and longevity of your products. Visit our website today to learn more about our products and how they can help you navigate the challenges of humidity.

Explore our range of desiccant solutions to find the right fit for your industry. Contact us for a custom desiccant solution or call us at 0858124188.

Read more

FDA-Approved BioDry Natural Clay Desiccant: Mastering Humidity Control

Silica Gel for Moisture Control: Industrial Applications and Humidity Regulation

A Container Desiccant Study on Temperature and Relative Humidity

Protect Your Piano from Humidity and Moisture Damage

Effective Humidity Control for Camera Storage

เปิดเผย! ข้อดีของการใช้ Humidity Indicator Cards ที่จะช่วยปกป้องสินค้าของคุณ

How to Protect Your Car from Moisture Damage

External links:

Humidity Control In Food Industry

The Effects of Humidity on Pharmaceuticals

(PDF) The Effect of Humidity on the Worker Productivity

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้