The Benefits of Using Molecular Sieves in Gas Drying Applications

| Topic | Key Takeaways |

|---|---|

| Importance of Gas Drying | Gas drying is crucial in various industries to prevent moisture-related issues such as corrosion and freezing. |

| Role of Molecular Sieves | Molecular sieves are highly effective in adsorbing water molecules from gases, ensuring thorough drying. |

| Types of Molecular Sieves for Gas Drying | Different molecular sieves, such as 3A, 4A, and 13X, are suited to specific gas drying applications based on pore size. |

| Advantages Over Other Drying Methods | Molecular sieves provide high efficiency, durability, and reusability, making them more economical in the long run. |

| Industrial Applications | Commonly used in natural gas processing, petrochemical industries, and air separation to ensure gas purity and quality. |

Table of Contents

“Unlock the Power of Molecular Sieves for Maximum Gas Drying Performance!”

Introduction

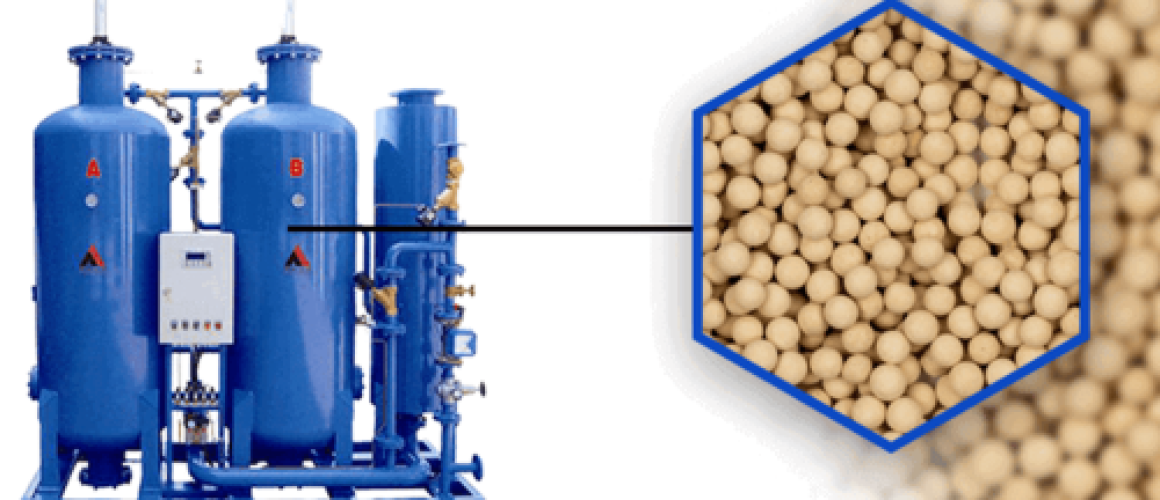

Molecular sieves are a type of desiccant material that can be used to dry gases. They are composed of a porous material that is capable of adsorbing water molecules from the gas stream. Molecular sieves are used in a variety of gas drying applications, such as air drying, natural gas drying, and industrial gas drying. The use of molecular sieve desiccants in gas drying applications offers several benefits, including improved product quality, increased efficiency, and cost savings. This article will discuss the benefits of using molecular sieves in gas drying applications.

How Molecular Sieves Improve the Efficiency of Gas Drying Applications

Molecular sieve adsorbents are a type of desiccant used to remove water vapor from gas streams. They are commonly used in gas drying applications to improve the efficiency of the process. Molecular sieves are highly effective at removing water vapor from gas streams because they are able to selectively adsorb water molecules while allowing other gases to pass through.

Molecular sieves are composed of a porous material with a uniform pore size. This pore size is typically between 3 and 10 angstroms, which is small enough to allow only water molecules to pass through. The water molecules are then adsorbed onto the surface of the sieve, leaving the other gases in the stream unaffected.

The efficiency of a molecular sieve is determined by its adsorption capacity. This is the amount of water vapor that can be adsorbed by the sieve before it becomes saturated. The higher the adsorption capacity, the more efficient the sieve will be at removing water vapor from the gas stream.

Molecular sieves are also highly efficient because they can be regenerated. This means that after the sieve has become saturated with water vapor, it can be heated to release the water molecules and restore its adsorption capacity. This allows the sieve to be reused multiple times, making it a cost-effective solution for gas drying applications.

In summary, molecular sieves are an effective and efficient solution for removing water vapor from gas streams. They are composed of a porous material with a uniform pore size that is small enough to allow only water molecules to pass through. The adsorption capacity of the sieve determines its efficiency, and it can be regenerated to restore its adsorption capacity and allow for multiple uses.

The Cost Benefits of Using Molecular Sieves in Gas Drying Applications

Molecular sieves are a type of desiccant used in gas drying applications. They are highly effective at removing moisture from gas streams, and their use can provide a number of cost benefits.

One of the primary cost benefits of using molecular sieves is their low cost. Molecular sieves are relatively inexpensive compared to other desiccants, and they can be used for a variety of applications. This makes them an attractive option for companies looking to reduce their costs.

Another cost benefit of using molecular sieves is their high efficiency. Molecular sieves are able to remove moisture from gas streams quickly and effectively. This means that companies can reduce their energy costs by using molecular sieves, as they will not need to run their drying equipment for as long.

Molecular sieves also have a long lifespan. They can be used for many years without needing to be replaced, which can save companies money in the long run. Additionally, molecular sieves are easy to maintain, which can further reduce costs.

Finally, molecular sieves are environmentally friendly. They do not produce any hazardous waste, and they can be recycled or reused. This makes them an attractive option for companies looking to reduce their environmental impact.

In conclusion, using molecular sieves in gas drying applications can provide a number of cost benefits. They are relatively inexpensive, highly efficient, have a long lifespan, and are environmentally friendly. For these reasons, they are an attractive option for companies looking to reduce their costs.

The Environmental Benefits of Using Molecular Sieves in Gas Drying Applications

Molecular sieves are a type of desiccant used in gas drying applications. They are highly effective at removing water vapor from gas streams, making them an ideal choice for a variety of industrial processes. In addition to their effectiveness, molecular sieves offer a number of environmental benefits.

First, molecular sieves are highly efficient at removing water vapor from gas streams. This means that less energy is required to dry the gas, resulting in lower energy consumption and fewer emissions. Additionally, molecular sieves are non-toxic and non-corrosive, making them safe to use in a variety of applications.

Second, molecular sieves are reusable. This means that they can be used multiple times before needing to be replaced, reducing the amount of waste generated. Furthermore, molecular sieves can be regenerated, meaning that they can be used for an even longer period of time. This reduces the need for new sieves, further reducing waste.

Finally, molecular sieves are highly durable. This means that they can withstand a variety of conditions, including extreme temperatures and pressures. This makes them ideal for use in a variety of industrial processes, as they can be used in a wide range of applications without needing to be replaced.

In conclusion, molecular sieves offer a number of environmental benefits. They are highly efficient at removing water vapor from gas streams, reducing energy consumption and emissions. Additionally, they are reusable and can be regenerated, reducing the amount of waste generated. Finally, they are highly durable, making them ideal for use in a variety of industrial processes.

The Safety Benefits of Using Molecular Sieves in Gas Drying Applications

Molecular sieves are a type of desiccant used in gas drying applications to remove water vapor and other impurities from a gas stream. They are highly effective at removing moisture and other contaminants, making them an ideal choice for a variety of industrial applications. In addition to their effectiveness, molecular sieves also offer a number of safety benefits that make them an attractive option for gas drying applications.

One of the primary safety benefits of using molecular sieves is their ability to reduce the risk of fire and explosion. When moisture is present in a gas stream, it can create a combustible mixture that can ignite and cause an explosion. By removing the moisture from the gas stream, molecular sieves can help to reduce the risk of fire and explosion.

Another safety benefit of using molecular sieves is their ability to reduce the risk of corrosion. Moisture in a gas stream can cause corrosion of metal components, leading to costly repairs and downtime. By removing the moisture from the gas stream, molecular sieves can help to reduce the risk of corrosion and extend the life of the equipment.

Finally, molecular sieves can also help to reduce the risk of contamination. Contaminants such as dust, dirt, and other particles can be present in a gas stream, and these contaminants can cause damage to equipment and reduce the efficiency of the system. By removing these contaminants, molecular sieves can help to reduce the risk of contamination and improve the performance of the system.

In summary, molecular sieves offer a number of safety benefits that make them an attractive option for gas drying applications. They can help to reduce the risk of fire and explosion, corrosion, and contamination, making them an ideal choice for a variety of industrial applications.

The Versatility of Molecular Sieves in Gas Drying Applications

Molecular sieves are a type of desiccant material that are used in a variety of gas drying applications. They are highly effective at removing moisture from gas streams, and their versatility makes them a popular choice for many industries.

Molecular sieves are composed of a porous material that is capable of adsorbing water molecules from a gas stream. This material is usually a type of zeolite, which is a crystalline material with a highly porous structure. The pores of the zeolite are small enough to allow only water molecules to pass through, while larger molecules such as oxygen and nitrogen are blocked. This allows the molecular sieve to effectively remove moisture from the gas stream.

Molecular sieves are used in a variety of gas drying applications, including air drying, natural gas drying, and hydrogen drying. In air drying applications, molecular sieves are used to remove moisture from compressed air, which is then used in industrial processes.

Molecular Sieves for Air Drying and Purification are essential in maintaining clean, dry air for industrial applications. By adsorbing moisture and contaminants, they protect equipment, enhance air quality, and ensure efficient operations in sectors like healthcare, automotive, and manufacturing. Discover how molecular sieves are revolutionizing air purification with their superior moisture control and adsorption capabilities—read on to learn more about their vital role across industries.

In natural gas drying applications, molecular sieves are used to remove moisture from natural gas before it is used as a fuel source. In hydrogen drying applications, molecular sieves are used to remove moisture from hydrogen gas before it is used in fuel cells.

In addition to gas drying, molecular sieves are pivotal in ethanol dehydration, where they ensure fuel-grade purity. For a deeper dive, see our post on Molecular Sieves for Ethanol Dehydration: Ensuring Purity and Efficiency.

Molecular sieves are also used in other applications, such as the removal of carbon dioxide from natural gas. In this application, the molecular sieve is used to adsorb the carbon dioxide molecules from the gas stream, allowing the remaining gas to be used as a fuel source.

Molecular sieves are a versatile and effective desiccant material that can be used in a variety of gas drying applications. Their ability to adsorb water molecules from a gas stream makes them an ideal choice for many industries.

Gas Drying and Other Essential Molecular Sieve Processes

Gas drying is a critical application for molecular sieves, helping industries protect equipment, improve product quality, and ensure efficient operations. However, gas drying is only one of the many molecular sieve processes that enhance industrial efficiency and purity. Molecular sieves also play key roles in gas separation, adsorption, and catalytic support, each process tailored to meet specific industry needs.

To explore the full range of molecular sieve applications, visit our comprehensive guide on Key Molecular Sieve Processes.

Refrigerant Applications: Molecular Sieves Beyond Gas Drying

For industries dealing with refrigerants, molecular sieves provide essential moisture control, enhancing system longevity and preventing issues like ice formation and contamination. To learn more about how these sieves support refrigerant systems in both HVAC and other refrigeration units, explore our in-depth article on Molecular Sieves for Refrigerants.

Frequently Asked Questions

What are molecular sieves used for in gas drying?

Molecular sieves are used in gas drying applications to remove moisture from gases. Their microporous structure allows them to adsorb water molecules efficiently, ensuring that gases remain dry and free from contaminants.

Why is gas drying important in industrial applications?

Gas drying is essential in many industries to prevent issues such as corrosion, freezing, and contamination. Removing moisture from gases helps maintain the quality and reliability of various industrial processes, particularly in sectors like petrochemicals and natural gas processing.

Which types of molecular sieves are best for gas drying?

Molecular sieves such as 3A, 4A, and 13X are commonly used for gas drying. The choice depends on the specific requirements of the application. For instance, 3A sieves are effective for drying gases with smaller molecules, while 4A and 13X are suitable for larger molecules or applications needing a higher adsorption capacity.

How do molecular sieves differ from other drying agents like silica gel?

Molecular sieves have a higher adsorption capacity, especially at low humidity levels, and can target specific molecules based on size. This makes them more effective and selective than other drying agents like silica gel, particularly in applications requiring precise moisture control.

Are molecular sieves reusable?

Yes, molecular sieves can be regenerated and reused. This process usually involves heating to remove the adsorbed moisture, allowing the sieves to be restored to their original state and reused in further drying cycles.

What industries benefit from using molecular sieves for gas drying?

Industries such as natural gas processing, petrochemicals, air separation, and electronics benefit from using molecular sieves in gas drying. They help maintain gas purity, improve process efficiency, and protect equipment from moisture-related damage.

What are the main advantages of using molecular sieves in gas drying?

Molecular sieves offer high efficiency, durability, and selective adsorption, making them cost-effective for long-term use. They are capable of adsorbing moisture even at low temperatures and low relative humidity, making them highly reliable in critical applications.

How long do molecular sieves last in gas drying applications?

The lifespan of molecular sieves depends on the application and operating conditions. However, with proper regeneration and maintenance, they can last for several years, making them a durable option for gas drying.

Can molecular sieves remove other impurities besides water?

Yes, molecular sieves can also adsorb other molecules such as carbon dioxide, sulfur compounds, and hydrocarbons, depending on their pore size. This makes them versatile in various purification and drying applications.

How do I select the right molecular sieve for my gas drying needs?

The selection depends on factors such as the type of gas, desired purity level, operating temperature, and specific contaminants present. Consulting with a molecular sieve supplier can help determine the best type and grade for your specific application.

Conclusion

Molecular sieves play a critical role in gas drying applications, offering numerous benefits such as high adsorption capacity, selective moisture removal, and long-term cost-effectiveness. Whether in natural gas processing, petrochemicals, or air separation, molecular sieves are essential for ensuring gas purity and protecting industrial processes from moisture-related issues.

For more detailed insights into the versatility of molecular sieves across various industries, explore our post on Exploring the Many Uses of Molecular Sieves in Different Industries. Additionally, you might be interested in our Previous Post on Green Energy Applications or our Comprehensive Guide to Molecular Sieves for an in-depth look at this fascinating material.

If you’re considering molecular sieves for your own applications, visit our Product Page to explore the options available. To further understand their application in natural gas processing, you can also check out this External Link on Natural Gas Processing for a broader perspective on how molecular sieves contribute to the industry.