The Science Behind Shipping Container Desiccants

Desiccant Types and Their Key Characteristics

| Desiccant Type | Material | Absorption Capacity | Best For |

|---|---|---|---|

| Silica Gel | Silicon Dioxide | Moderate | Electronics, pharmaceuticals |

| Calcium Chloride | Calcium-based | High | Food, long-haul shipping |

| Activated Clay | Natural Clay | Low to Moderate | Short-term shipping, textiles |

Table of Contents

I. Introduction

Shipping container desiccants play a crucial role in protecting your valuable cargo from moisture damage. In this article, we will uncover the science behind shipping container desiccants, focusing on three popular products: InterDry Power Desiccant, Ecobag, and KeepDry. By understanding the principles and technology behind these desiccants, you can make informed decisions that ensure the safety and integrity of your cargo.

II. The Science of Moisture Absorption

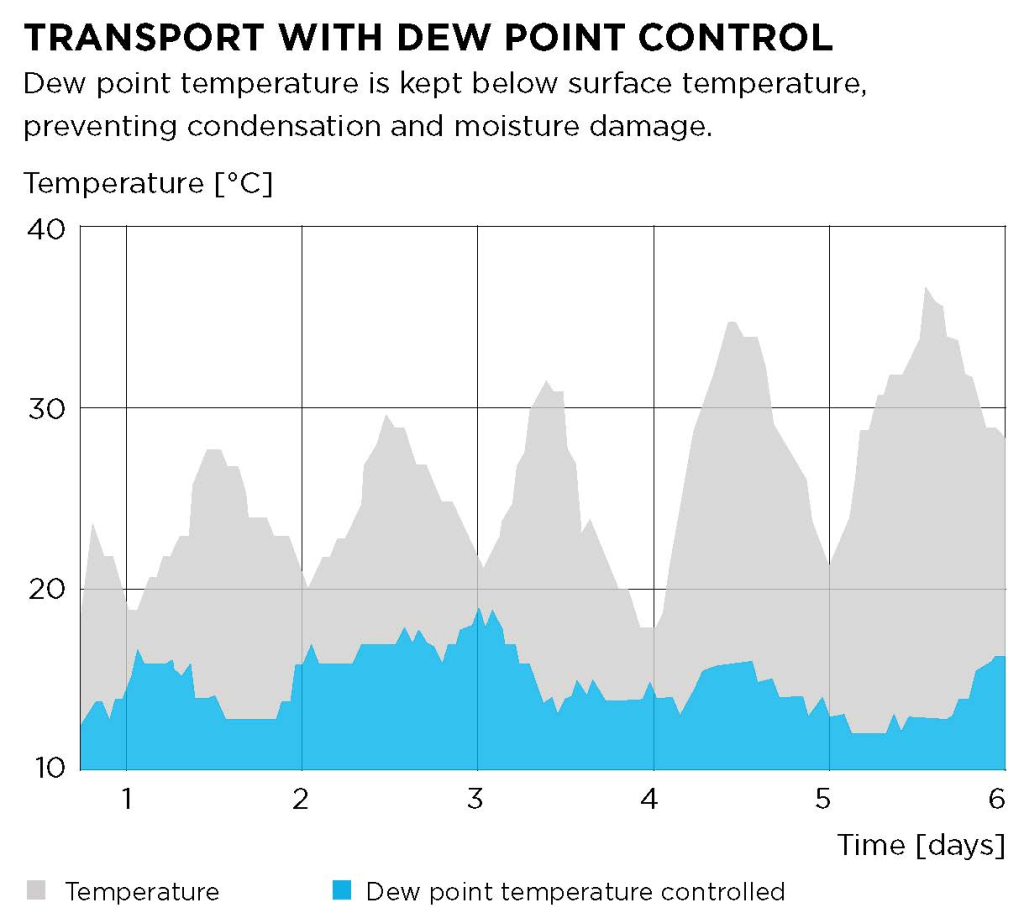

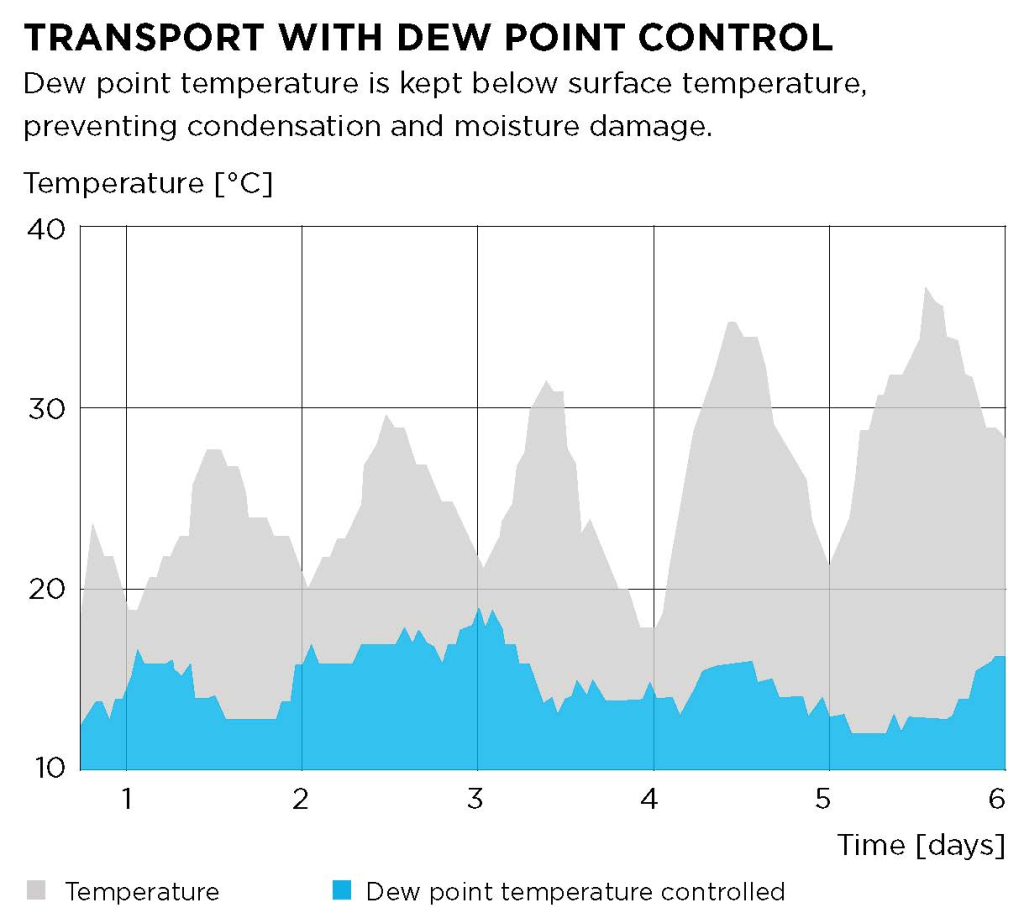

A. Relative humidity and dew point

Relative humidity is the ratio of the amount of water vapor in the air to the maximum amount of water vapor the air can hold at a given temperature. The dew point, on the other hand, is the temperature at which the air becomes saturated and water vapor begins to condense. In a shipping container, if the relative humidity exceeds the dew point, condensation can form, causing damage to the cargo.

B. How desiccants work

Desiccants are substances that attract and hold water molecules from the surrounding environment. They work by creating a lower vapor pressure, causing the moisture in the air to move towards the desiccant. Once the water molecules are absorbed by the desiccant, they are held within its structure, effectively reducing the humidity inside the container and preventing condensation.

Common Issues Prevented by Desiccants

| Issue | Goods Affected | Desiccant Solution |

|---|---|---|

| Condensation (Container Rain) | Electronics, food | Silica Gel, Calcium Chloride |

| Mold Growth | Textiles, leather | Calcium Chloride |

| Corrosion | Machinery, metals | Activated Clay, Calcium Chloride |

III. InterDry Power Desiccant: Superior Absorption Capacity

A. Composition and technology

InterDry Power Desiccant is a high-performance container desiccant made from a unique combination of materials, including calcium chloride and modified starch. This formulation enables it to absorb moisture more effectively than traditional desiccants. The absorbed moisture is converted into a gel-like substance, preventing leakage and ensuring that the desiccant remains efficient throughout the shipping process.

B. Benefits and applications

InterDry Power Desiccant is designed to protect various types of cargo, including agricultural products, wood products, leather, metals, electrical goods, and textiles. By absorbing excess moisture, it prevents mold, fungus, mildew, and corrosion from damaging your valuable goods. Moreover, its high absorption capacity allows for fewer units to be used, saving both space and money.

Impact of Humidity on Different Goods

| Humidity Level (%) | Effect on Electronics | Effect on Textiles | Effect on Food |

|---|---|---|---|

| 40-60% | Safe | Minimal mold risk | Fresh, minimal spoilage |

| 60-80% | Corrosion risk | Moderate mold risk | Increased spoilage |

| 80-100% | Severe corrosion risk | High mold risk | High spoilage, bacterial growth |

IV. Ecobag: Environmentally Friendly Desiccant Solution

A. Composition and technology

Ecobag is an eco-friendly container desiccant made from a blend of attapulgite, bentonite, and calcium chloride. The product is packed in a spunbond bag with a convenient hook, allowing for easy installation and removal. Ecobag is capable of absorbing between 50-60% of its own weight in moisture, providing effective humidity control during shipping.

B. Benefits and applications

As an environmentally responsible desiccant solution, Ecobag is suitable for use with agricultural and food products. Its high absorption capacity, coupled with its non-toxic and environmentally safe composition, makes it an ideal choice for cargo preservation. Furthermore, Ecobag is available in various sizes to accommodate different shipping requirements.

V. KeepDry: Silica Gel Desiccant for Shipping Containers

A. Composition and technology

KeepDry is a shipping container desiccant composed of 100% silica gel, a porous, granular material known for its excellent moisture-absorbing properties. Packed in a spunbond bag with a hook for easy installation, KeepDry can absorb around 35% of its own weight in moisture, providing reliable humidity control during transportation.

B. Benefits and applications

KeepDry is a versatile desiccant suitable for a wide range of cargo types, including electronics, textiles, and metal goods. Its compact design allows for efficient use of space, and its high absorption capacity ensures the protection of your cargo from moisture-related damage. KeepDry’s silica gel composition is non-toxic and environmentally friendly, making it a safe choice for various applications.

VI. Choosing the Right Desiccant for Your Cargo

A. Considerations for selection

When selecting the appropriate desiccant for your shipping container, it’s essential to consider factors such as the type of cargo, the shipping route and conditions, and the required absorption capacity. Additionally, environmental considerations, such as the desiccant’s ecological impact, may be important to some businesses.

B. Comparing InterDry Power Desiccant, Ecobag, and KeepDry

InterDry Power Desiccant is the best choice for those looking for the highest absorption capacity and superior performance. Ecobag, on the other hand, offers an environmentally friendly alternative for those shipping agricultural and food products. KeepDry, with its silica gel composition, is a versatile and compact option suitable for a wide range of cargo types.

VII. Maximizing the Effectiveness of Your Desiccant

A. Proper placement and installation

To ensure maximum effectiveness, it is crucial to install the desiccants correctly within the shipping container. Place them strategically around the cargo to ensure even distribution of humidity control. Follow the manufacturer’s recommendations for the appropriate number of units to use based on the size of the container and the type of cargo.

B. Monitoring humidity levels

Regularly monitoring the humidity levels within your shipping container can help identify any potential moisture issues early on, allowing you to take corrective action if necessary. Humidity indicator cards or data loggers can be used to track humidity levels throughout the shipping process.

VIII. A New Era of Cargo Protection

In conclusion, understanding the science behind shipping container desiccants is essential for making informed decisions about cargo protection. By selecting the right desiccant for your specific needs, you can ensure the safety and integrity of your valuable goods during transportation.

IX. Frequently Asked Questions

What is the best desiccant for shipping containers?

The best desiccant for shipping containers depends on the type of cargo, shipping conditions, and specific requirements. InterDry Power Desiccant offers the highest absorption capacity, while Ecobag is suitable for environmentally conscious shippers, and KeepDry is a versatile option for various cargo types.

What is a desiccant bag?

A desiccant bag is a container filled with moisture-absorbing materials like silica gel, calcium chloride, or clay minerals. They are used to control humidity inside shipping containers and protect cargo from moisture-related damage.

How much desiccant do I need for a shipping container?

The amount of desiccant needed for a shipping container depends on factors such as container size, type of cargo, and shipping conditions. It is best to follow the manufacturer’s recommendations and adjust based on your specific requirements.

How do you moisture proof a shipping container?

To moisture-proof a shipping container, use appropriate desiccants, place them strategically around the cargo, ensure proper ventilation, and monitor humidity levels throughout the shipping process. Regularly inspect the container for any signs of leaks or damage that may compromise its moisture protection.

How long do desiccant bags last?

The lifespan of desiccant bags depends on the absorption capacity of the desiccant material and the humidity levels inside the container. Most desiccants are designed to last for the entire duration of a shipment, but it’s essential to monitor their effectiveness and replace them as needed.

What is the difference between silica and desiccant?

Silica gel is a specific type of desiccant material made from silicon dioxide. Desiccant, on the other hand, is a general term that refers to any moisture-absorbing substance used to control humidity. Other common desiccant materials include calcium chloride and clay minerals.

How can I tell when it’s time to replace my desiccants?

The need to replace desiccants depends on the desiccant type and the specific conditions inside the shipping container. Some desiccants, like silica gel, may change color when they reach their absorption capacity. Others, like InterDry Power Desiccant, convert absorbed moisture into a cake, signaling the need for replacement. Always follow the manufacturer’s guidelines for monitoring and replacing desiccants.

Can I mix different types of desiccants in a shipping container?

While it is possible to mix different types of desiccants in a shipping container, it is essential to consider their compatibility and the requirements of your cargo. Using multiple desiccant types may lead to uneven moisture distribution and inadequate protection. Consult with experts or follow the manufacturer’s recommendations when combining desiccants.

How do I position desiccants inside the shipping container for optimal performance?

The positioning of desiccants inside the shipping container plays a crucial role in moisture control. Place desiccant bags evenly throughout the container, focusing on areas with higher moisture content or where condensation is likely to form. Ensure proper air circulation around the desiccants to maximize their effectiveness.

How do I store desiccants before use?

Store desiccants in a cool, dry place, away from direct sunlight and moisture. Keep them sealed in their original packaging until ready for use to prevent premature absorption of moisture.

Are there any specific guidelines for using desiccants with food or pharmaceutical products?

When using desiccants with food or pharmaceutical products, ensure that they are food-safe and compliant with relevant regulations. Many desiccants, like InterDry Power Desiccant and Ecobag, are non-toxic and safe for use with food and pharmaceuticals. Always follow the manufacturer’s guidelines and any applicable regulations for your specific cargo.

The Ultimate Guide to Shipping Container Desiccants: InterDry Power Desiccant, Ecobag, and KeepDry

Top Industries That Benefit from Using Shipping Container Desiccants

https://www.sciencedirect.com/topics/medicine-and-dentistry/desiccant

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้