Cold Weather Shipping

Acclimation and Best Practices

Table of Contents

I. Introduction

A. Importance of Cold Weather Shipping Acclimation

Cold weather shipping acclimation is an essential process for businesses and industries that rely on the safe transportation of their products during winter months. As temperatures drop and humidity levels fluctuate, goods can become vulnerable to damage, spoilage, and other quality concerns. Ensuring proper acclimation can help maintain product integrity, reduce losses, and ultimately, contribute to customer satisfaction.

B. Challenges Faced During Cold Weather Shipping

Shipping goods during cold weather presents several unique challenges that must be addressed to ensure successful delivery. Some of the key issues include:

- Temperature fluctuations: Drastic changes in temperature during transportation can cause condensation, which can lead to moisture-related damage in various goods, such as electronics, textiles, and food items.

- Humidity control: Maintaining a consistent humidity level within the shipping container is crucial to preventing mold and mildew growth, corrosion, and other moisture-related problems.

- Acclimation procedures: Different goods require different acclimation processes to adapt to the cold environment and minimize the risk of damage. Failure to follow the appropriate procedures can result in costly losses and damaged products.

C. The Role of Container Desiccants in Protecting Goods

Container desiccants play a vital role in preserving the quality of goods shipped in cold weather. These moisture-absorbing materials help maintain a stable environment within the shipping container by controlling humidity levels and reducing the risk of condensation. By incorporating container desiccants in the shipping process, businesses can protect their goods from potential damage caused by cold weather conditions and ensure that their products arrive in the best possible condition.

II. Understanding Cold Weather Shipping Acclimation

A. Definition and Significance

Cold weather shipping acclimation refers to the process of preparing and adapting goods for transportation during cold temperatures, ensuring they can withstand environmental changes and maintain their quality upon arrival. Proper acclimation is crucial for businesses that rely on the safe and efficient delivery of their products, especially those sensitive to temperature and humidity changes. By understanding and implementing appropriate acclimation procedures, companies can mitigate the risk of product damage, minimize losses, and maintain customer satisfaction.

B. Factors Affecting Acclimation

- Temperature Fluctuations

One of the main challenges during cold weather shipping is coping with drastic temperature changes, which can lead to condensation inside the shipping container. This condensation can cause moisture-related damage to various goods, such as electronics, textiles, and food items. Proper acclimation procedures, including adequate insulation and temperature control measures, are essential for mitigating these risks.

- Humidity Levels

Humidity control is a critical factor in the acclimation process, as high humidity levels can cause mold, mildew, and corrosion, potentially damaging the goods being shipped. By incorporating moisture-absorbing materials like container desiccants and using appropriate packaging materials, businesses can maintain a stable humidity level within the shipping container and protect their products from moisture-related damage.

- Type of Goods Being Shipped

The type of goods being shipped plays a significant role in determining the appropriate acclimation procedures. Different products have varying sensitivities to temperature and humidity changes, necessitating tailored acclimation methods. For example, electronics require careful protection against moisture and condensation, while perishable food items need to be maintained at specific temperatures to prevent spoilage. Understanding the unique requirements of each product and implementing the proper acclimation techniques is essential for successful cold weather shipping.

For instance:

- Electronics and IT equipment: These items are highly sensitive to moisture and require careful protection against condensation. Proper packaging materials, insulation, and the use of container desiccants are vital to maintaining a stable environment during transportation.

- Perishable food items: Temperature control is crucial for preventing spoilage and ensuring the safe delivery of perishable goods. Insulated containers, temperature monitoring, and adequate ventilation can help maintain optimal conditions during cold weather shipping.

- Textiles and clothing: Moisture and humidity can cause mold and mildew growth on fabrics, potentially damaging the products. Using moisture-absorbing materials like container desiccants and properly ventilating the shipping container can help protect textiles during transportation.

III. Goods Affected by Cold Weather Shipping

A. IT Equipment

- Sensitivity to Temperature and Humidity Changes

IT equipment, such as servers, computers, and other electronic devices, is highly sensitive to changes in temperature and humidity. Fluctuations in environmental conditions can cause condensation and moisture buildup, leading to potential damage, malfunctions, and reduced product lifespan. As a result, proper acclimation and protection measures are crucial when shipping IT equipment in cold weather.

- Acclimation Procedures and Best Practices

To ensure the safe transportation of IT equipment, several acclimation procedures and best practices should be followed:

- Use proper packaging materials and insulation to protect the equipment from temperature fluctuations and condensation.

- Utilize container desiccants to maintain optimal humidity levels within the shipping container.

- Allow the IT equipment to acclimate to its new environment before powering it on, following manufacturer guidelines on acclimation times.

- Monitor temperature and humidity levels during transportation to ensure stable conditions are maintained.

B. Rice

- Moisture Sensitivity and Spoilage Risks

Rice is highly sensitive to moisture, making it susceptible to spoilage during cold weather shipping. Excess moisture can lead to mold growth, discoloration, and a reduction in the overall quality of the rice. As such, it is crucial to take appropriate precautions when shipping rice in cold temperatures.

- Precautions and Best Practices for Shipping Rice

To ensure the safe and efficient transportation of rice, consider the following best practices:

- Use moisture-proof packaging materials, such as polyethylene bags or vacuum-sealed containers, to protect the rice from external moisture.

- Utilize container desiccants to maintain optimal humidity levels within the shipping container and prevent condensation.

- Monitor temperature and humidity levels during transportation to ensure that stable conditions are maintained and to prevent any moisture-related damage.

- Store the rice away from other goods that may release moisture or odors, as rice can easily absorb these, leading to spoilage or contamination.

See also: The Benefits of Using Desiccants in the Agriculture Industry

C. Steel

- Corrosion and Rust Concerns

Steel, though durable and strong, can be susceptible to corrosion and rust when exposed to moisture during cold weather shipping. Temperature fluctuations and condensation can cause moisture to accumulate on the steel surfaces, leading to the formation of rust and compromising the structural integrity of the material.

- Best Practices for Shipping Steel in Cold Weather

To protect steel from corrosion and rust during cold weather shipping, consider implementing the following best practices:

- Apply a protective coating, such as rust inhibitors or anti-corrosion paint, to the steel surfaces before shipping. This can help prevent moisture from coming into direct contact with the steel and minimize the risk of rust formation.

- Use proper packaging materials, such as moisture-resistant covers or barrier films, to shield the steel from external moisture and condensation.

- Incorporate container desiccants to maintain appropriate humidity levels within the shipping container, reducing the potential for condensation and moisture buildup.

- Regularly inspect and monitor the steel during transportation to ensure that it remains free from moisture and rust.

D. Other Goods (Textiles, Electronics, etc.)

- Textiles

Textiles, such as clothing, fabrics, and carpets, can be susceptible to damage during cold weather shipping due to their sensitivity to moisture and humidity. Mold, mildew, and odors can develop when textiles are exposed to excess moisture, compromising the quality and appearance of the products.

Best Practices for Shipping Textiles in Cold Weather:

- Use moisture-resistant packaging materials to protect textiles from external moisture and condensation. Protect packages shipping in cold.

- Incorporate container desiccants to maintain optimal humidity levels within the shipping container, preventing mold and mildew growth.

- Allow textiles to acclimate to their new environment before unpacking, following manufacturer guidelines on acclimation times.

- Store textiles away from other goods that may release moisture or odors to prevent contamination.

- Electronics

Electronics, such as smartphones, tablets, and other gadgets, are highly sensitive to temperature and humidity changes. Cold weather shipping can cause condensation and moisture buildup, leading to potential damage, malfunctions, and reduced product lifespan.

Best Practices for Shipping Electronics in Cold Weather:

- Use proper packaging materials, such as anti-static bags and moisture-resistant covers, to protect electronics from temperature fluctuations and condensation.

- Utilize container desiccants to maintain stable humidity levels within the shipping container, reducing the risk of moisture-related damage.

- Allow electronics to acclimate to their new environment before powering them on, following manufacturer guidelines on acclimation times.

- Monitor temperature and humidity levels during transportation to ensure stable conditions are maintained.

IV. Container Desiccants: Types, Uses, and Benefits

A. Types of Container Desiccants

- Silica Gel

Silica gel is a popular and widely used desiccant made from silicon dioxide. It effectively absorbs and holds water vapor, making it ideal for controlling humidity levels in shipping containers. Silica gel is available in various forms, such as beads or granules, and can be used in small sachets or large bags, depending on the size of the shipment.

- Calcium Chloride

Calcium chloride is another popular container desiccant that effectively absorbs moisture from the air. It is a hygroscopic salt that forms a gel as it absorbs water, making it highly effective at controlling humidity levels. Calcium chloride desiccants are often used in combination with other desiccants to provide optimal moisture protection for various goods.

Calcium chloride is known for its high absorption capacity and effectiveness in maintaining low humidity levels. It is typically used in shipping containers for bulk goods, such as grains, and is available in various forms, including bags, pouches, or sheets.

Activated clay, also known as bentonite clay or montmorillonite clay, is a naturally occurring desiccant that can absorb moisture and odors. It is often used as an eco-friendly alternative to other desiccants, as it is non-toxic and can be easily disposed of after use. Activated clay desiccants are commonly used to protect goods such as textiles, leather, and electronics from moisture damage.

Activated alumina is a porous form of aluminum oxide that is highly effective at absorbing moisture from the air. It is often used in high-humidity environments and is ideal for protecting goods that are sensitive to moisture, such as pharmaceuticals, electronics, and chemicals.

B. Uses of Container Desiccants

- Moisture Control

Container desiccants play a crucial role in controlling moisture levels during shipping, preventing condensation and humidity-related damage to goods. By maintaining optimal humidity levels within the shipping container, desiccants can protect sensitive products from moisture-related issues, such as rust, mold, and spoilage.

- Mold and Mildew Prevention

By absorbing excess moisture, container desiccants help prevent the growth of mold and mildew on various goods, such as textiles, food, and paper products. This ensures that products remain in good condition during transportation and storage, reducing the risk of product losses and customer complaints.

- Extended Shelf Life of Goods

Container desiccants can help extend the shelf life of perishable and moisture-sensitive goods by maintaining optimal humidity levels. This reduces the risk of spoilage and deterioration, ensuring that products arrive at their destination in the best possible condition.

C. Benefits of Using Container Desiccants

- Cost Savings

Using container desiccants during cold weather shipping can lead to significant cost savings for businesses. By effectively controlling humidity levels within the shipping container and preventing condensation, container desiccants reduce the risk of moisture-related damage to products. This, in turn, minimizes the need for product replacements, refunds, or additional shipping costs associated with damaged goods. Moreover, container desiccants are relatively inexpensive and can be easily integrated into the shipping process, making them a cost-effective solution for businesses.

- Product Quality Preservation

Maintaining optimal humidity levels within the shipping container is crucial for preserving the quality of various goods during cold weather shipping. Container desiccants help to achieve this by absorbing excess moisture, preventing mold, mildew, corrosion, and other moisture-related issues. As a result, businesses can ensure that their products arrive in their intended condition, free from any damage caused by moisture exposure.

- Customer Satisfaction

Ensuring that products arrive in good condition is essential for maintaining customer satisfaction and building a positive brand reputation. By using container desiccants during cold weather shipping, businesses can effectively protect their products from moisture-related damage, ultimately leading to happier customers and more successful deliveries. This, in turn, can result in increased customer loyalty, positive reviews, and potential repeat business.

V. Cold Weather Shipping Best Practices

A. Proper Packaging and Insulation

- Selecting the Right Materials

Selecting the appropriate packaging materials is essential for protecting goods during cold weather shipping. Depending on the type of product being shipped, businesses should consider using moisture-resistant materials, such as polyethylene bags, vacuum-sealed containers, or barrier films, to shield their goods from external moisture and condensation. Additionally, using packaging materials with insulating properties, such as foam or bubble wrap, can help protect goods from temperature fluctuations and maintain a stable environment within the shipping container.

- Insulation Techniques

Proper insulation is crucial for maintaining a stable temperature within the shipping container and preventing condensation. Businesses should ensure that their goods are adequately insulated by:

- Wrapping products in insulating materials, such as foam or bubble wrap, to create a protective barrier against temperature fluctuations.

- Filling empty spaces within the shipping container with insulating materials, such as packing peanuts or air pillows, to minimize the impact of temperature changes on the goods.

- Using insulated shipping containers or thermal blankets, if necessary, to provide additional protection against cold temperatures.

B. Effective Use of Container Desiccants

- Proper Placement

To maximize the effectiveness of container desiccants during cold weather shipping, businesses should ensure that they are properly placed within the shipping container. Desiccants should be distributed evenly throughout the container to ensure optimal moisture absorption. Additionally, they should be placed in close proximity to moisture-sensitive goods and away from any direct sources of heat or ventilation, as these can reduce their effectiveness.

- Determining the Appropriate Quantity

Using the correct quantity of container desiccants is crucial for maintaining optimal humidity levels within the shipping container. To determine the appropriate amount of desiccants needed for a specific shipment, businesses should consider factors such as the size of the shipping container, the type and quantity of goods being shipped, and the expected temperature and humidity conditions during transportation. There are various tools and calculators available online that can help businesses estimate the required amount of desiccants for their specific shipping needs.

In conclusion, implementing effective cold weather shipping best practices, such as proper packaging and insulation and the effective use of container desiccants, can significantly reduce the risk of moisture-related damage to goods during transportation. By understanding the unique challenges associated with cold weather shipping and taking the necessary precautions, businesses can ensure the safe and successful delivery of their products, ultimately contributing to their overall success and customer satisfaction.

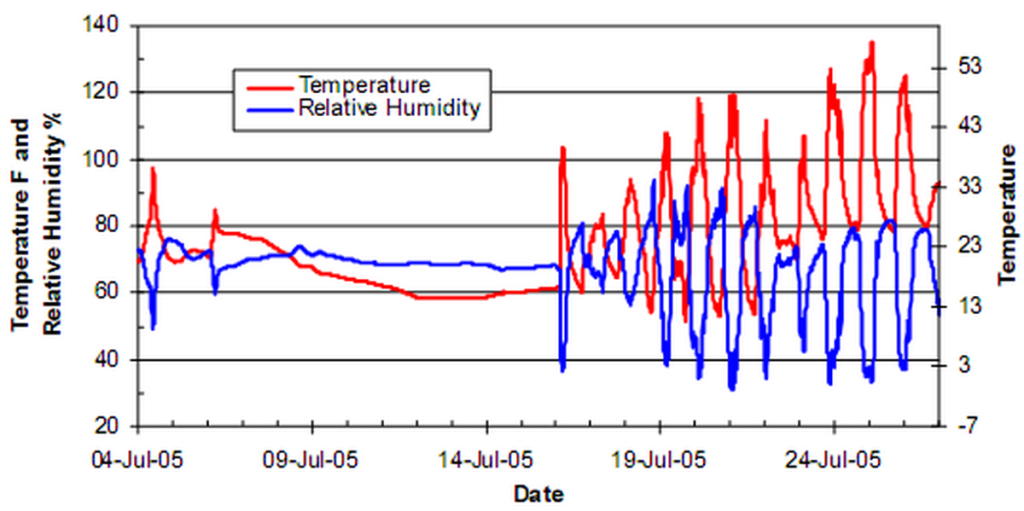

C. Monitoring temperature and humidity levels

- Importance of real-time monitoring

Real-time monitoring of temperature and humidity levels during cold weather shipping is crucial for ensuring the safe and successful delivery of goods. By keeping a close eye on these environmental factors, businesses can identify potential issues, such as condensation or temperature fluctuations, and take the necessary steps to mitigate any negative impacts on the products being shipped. Furthermore, real-time monitoring can help businesses optimize their shipping processes by identifying trends and patterns, allowing for better decision-making and improved shipping efficiency.

- Technologies available for tracking

Various technologies are available for tracking temperature and humidity levels during shipping, including:

- Data loggers: These devices can record temperature and humidity levels at regular intervals throughout the shipping process, providing businesses with valuable insights into the conditions experienced by their goods.

- Remote monitoring systems: These systems enable businesses to track temperature and humidity levels in real-time using wireless sensors and cloud-based software, allowing for quick identification and resolution of potential issues.

- Smart packaging: Innovations in packaging materials, such as temperature-sensitive labels or smart sensors, can provide real-time alerts when specific temperature or humidity thresholds are exceeded.

D. Acclimation procedures for different goods

- IT equipment

Allow IT equipment to gradually acclimate to the new environment before unpacking or powering on the devices, following manufacturer guidelines on acclimation times.

Inspect the internal components for any visible signs of condensation or moisture. If present, allow additional time for the equipment to dry completely before powering on.

- Rice

Ensure that the rice is properly packaged in moisture-resistant materials, such as vacuum-sealed bags or plastic containers, to prevent spoilage during shipping.

Allow the rice to gradually acclimate to the new environment before unpacking, following manufacturer guidelines on acclimation times. This helps prevent condensation from forming on the rice, which can lead to spoilage or mold growth.

- Steel

Ensure that steel products are properly coated or treated to prevent corrosion and rust during cold weather shipping. This may involve applying rust inhibitors, protective coatings, or using corrosion-resistant materials.

Allow steel products to gradually acclimate to the new environment before unpacking or installing. This helps prevent condensation from forming on the steel, which can lead to corrosion or rust.

- Other goods

- Textiles

a. Ensure textiles are properly packaged in moisture-resistant materials, such as plastic bags or vacuum-sealed containers, to protect against potential damage from moisture during cold weather shipping.

b. Allow textiles to gradually acclimate to the new environment before unpacking or displaying. This helps prevent condensation from forming on the textiles, which can lead to mold, mildew, or color bleeding.

- Electronics

a. Use anti-static packaging materials, such as anti-static bags or foam, to protect sensitive electronic components from potential damage due to static discharge during cold weather shipping.

b. Allow electronics to gradually acclimate to the new environment before unpacking or powering on the devices, following manufacturer guidelines on acclimation times. Inspect internal components for any visible signs of condensation or moisture. If present, allow additional time for the electronics to dry completely before powering on.

- Pharmaceuticals

a. Ensure pharmaceutical products are properly packaged in moisture-resistant and temperature-controlled packaging to maintain the stability and efficacy of the medications during cold weather shipping.

b. Allow pharmaceutical products to gradually acclimate to the new environment before unpacking or storing, following manufacturer guidelines on acclimation times and storage conditions.

VI. Case Studies

A. Successful Cold Weather Shipping of IT Equipment

A large IT equipment manufacturer faced challenges in shipping their sensitive products during cold weather, as extreme temperature fluctuations and humidity levels posed risks to the equipment. To overcome these challenges, the company implemented a comprehensive cold weather shipping strategy that included:

- Proper packaging: The IT equipment was packaged using moisture-resistant materials and insulated with foam padding to protect against temperature fluctuations.

- Container desiccants: Desiccants were placed strategically within the shipping container to control humidity levels and prevent condensation.

- Real-time monitoring: The company utilized remote monitoring systems to track temperature and humidity levels during transportation, allowing for quick identification and resolution of potential issues.

- Acclimation procedures: The IT equipment was allowed to gradually acclimate to the destination environment before unpacking and powering on the devices, following manufacturer guidelines on acclimation times.

As a result, the company successfully shipped their IT equipment without any moisture-related damage, ensuring customer satisfaction and maintaining product quality.

B. Rice Shipping and Moisture Control Using Container Desiccants

A rice exporter was experiencing losses due to moisture-related issues, such as mold and spoilage, during cold weather shipping. To address this problem, the company implemented the following measures:

- Proper packaging: The rice was packed in vacuum-sealed bags to protect against moisture and maintain product quality.

- Container desiccants: The company strategically placed desiccants throughout the shipping container to control humidity levels and prevent condensation.

- Acclimation procedures: The rice was allowed to gradually acclimate to the destination environment before unpacking, following manufacturer guidelines on acclimation times.

These measures effectively reduced moisture-related damage and spoilage during shipping, resulting in significant cost savings and improved customer satisfaction.

C. Steel Shipping and Corrosion Prevention in Cold Weather

A steel manufacturer faced challenges in shipping their products during cold weather, as condensation and humidity led to corrosion and rust. To overcome these challenges, the company implemented the following cold weather shipping best practices:

- Corrosion protection: The steel products were treated with rust inhibitors and protective coatings to prevent corrosion during transportation.

- Proper packaging: Steel products were wrapped in moisture-resistant materials, such as VCI (Volatile Corrosion Inhibitor) films, to protect against moisture and condensation.

- Container desiccants: Desiccants were placed strategically within the shipping container to control humidity levels and prevent condensation.

- Acclimation procedures: The steel products were allowed to gradually acclimate to the destination environment before unpacking or installing, following manufacturer guidelines on acclimation times.

As a result, the company successfully shipped their steel products without any corrosion or rust, ensuring customer satisfaction and maintaining product quality.

VII. Conclusion

A. Recap of the Importance of Cold Weather Shipping Acclimation

Cold weather shipping acclimation is an essential aspect of ensuring the safe and successful delivery of goods. As extreme temperature fluctuations and humidity levels can pose risks to various products, such as IT equipment, rice, steel, textiles, electronics, and pharmaceuticals, proper acclimation procedures are crucial in preventing moisture-related damage and maintaining product quality.

B. The Role of Container Desiccants in Maintaining Product Quality

Container desiccants play a vital role in cold weather shipping by controlling humidity levels within the shipping container and preventing condensation from forming on goods. By effectively absorbing excess moisture, desiccants help protect sensitive products from damage, ultimately contributing to cost savings, product quality preservation, and increased customer satisfaction.

C. Encouragement to Implement Best Practices for Successful Cold Weather Shipping

Implementing best practices for cold weather shipping, such as proper packaging, insulation, effective use of container desiccants, real-time monitoring of temperature and humidity levels, and adherence to acclimation procedures, is key to ensuring the safe and successful transportation of goods. By understanding the unique challenges associated with cold weather shipping and taking the necessary precautions, businesses can mitigate the risk of moisture-related damage to their products and ultimately contribute to their overall success and customer satisfaction.

สารดูดความชื้นคอนเทนเนอร์ขนส่ง – ป้องกันความเสียหายและเสนอคุณภาพสินค้า

https://www.containerhandbuch.de/chb_e/stra/index.html?/chb_e/stra/stra_03_00.html