7 Tips for Maximizing the Efficiency of Your Shipping Container Desiccants

Factors Affecting Desiccant Efficiency

| Factor | Impact on Desiccant Efficiency |

|---|---|

| Temperature Fluctuations | Increases moisture absorption rate |

| Container Size | Requires more desiccants in larger spaces |

| Duration of Transit | Longer transit demands higher capacity |

| Humidity Level | Higher humidity requires more desiccants |

Table of Contents

I. Introduction

Shipping container desiccants are essential for maintaining the integrity of your cargo, but maximizing their efficiency requires some know-how. In this article, we’ll discuss seven practical tips and advice on how to make the most of your shipping container desiccants for optimal cargo protection.

II. Choose the Right Moisture Absorber for Your Specific Needs

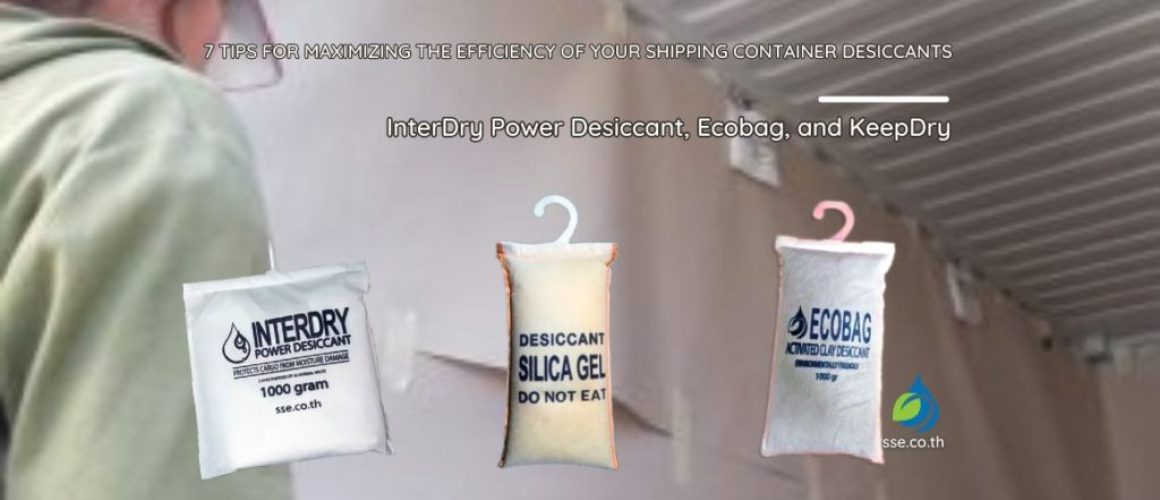

Different desiccants are designed for various purposes, so it’s crucial to select the right one for your specific shipping requirements. Some popular types of shipping container desiccants include InterDry Power Desiccant, Ecobag, and KeepDry. Each of these products has unique characteristics that make them suitable for specific applications. For instance, InterDry Power Desiccant is highly absorbent and can protect sensitive cargo such as electronics or pharmaceuticals, while Ecobag is an eco-friendly option that is perfect for organic or environmentally-conscious shippers.

To choose the right desiccant for your needs, consider factors such as the type of cargo, the shipping duration, and the environmental conditions that your shipment will be exposed to. By selecting the appropriate desiccant, you can ensure that your cargo is adequately protected against moisture damage.

Types of Shipping Desiccants

| Desiccant Type | Material | Best Use Case |

|---|---|---|

| Silica Gel | Silicon Dioxide | Short-term shipping, dry climates |

| Calcium Chloride | Calcium-based | High humidity, long-distance transport |

| Clay Desiccants | Natural Clay | Cost-effective for moderate conditions |

III. Determine the Correct Amount of Shipping Container Desiccant to Use

Using the appropriate amount of desiccant bags in your container is vital for optimal moisture control and cargo protection. The required quantity of moisture absorber will depend on factors such as the size of the container, the type and amount of cargo, and the expected humidity levels during transit. As a general rule, it’s better to use too much desiccant than too little, as excess moisture can cause significant damage to your cargo.

You can consult the desiccant manufacturer’s guidelines or seek the advice of a logistics expert to determine the correct amount of desiccant for your specific situation. By using the appropriate quantity of desiccant, you can maximize its effectiveness and ensure that your cargo is adequately protected against moisture-related damage.

Moisture Risk by Climate Zone

| Climate Zone | Humidity Level (%) | Moisture Risk |

|---|---|---|

| Tropical | 80-100% | High risk of condensation and mold |

| Temperate | 50-80% | Moderate risk of moisture accumulation |

| Arid | 20-50% | Low risk, but potential for dryness |

IV. Properly Position the Absorber Bags in the Container

Strategic placement of your desiccants can greatly enhance their performance and effectiveness. To ensure optimal moisture absorption, place the absorber bags in locations where they will have maximum exposure to the air inside the container. This may include areas near the container doors, along the sides of the container, and between layers of cargo.

Additionally, make sure that your desiccants are not obstructed by any objects or packaging materials, as this can hinder their ability to absorb moisture. By positioning your desiccants correctly, you can maximize their efficiency and protect your cargo from moisture damage.

Best Practices for Desiccant Placement

| Container Location | Reason for Placement |

|---|---|

| Near Container Doors | High exposure to external humidity |

| Along Walls and Ceiling | Where condensation commonly forms |

| Throughout Cargo Stacks | Even distribution ensures full protection |

V. Ensure Your Container is Sealed and Ventilated Correctly

A well-sealed and ventilated container is necessary for maximizing the efficiency of your shipping container desiccant. A properly sealed container will prevent the ingress of outside moisture, while adequate ventilation will allow the desiccant to effectively circulate and absorb moisture within the container.

Before loading your cargo, inspect the container for any signs of damage, such as holes or cracks, that may allow moisture to enter. Seal any openings or repair any damage to ensure that your container is watertight. Also, make sure that the container’s ventilation system is functioning properly to facilitate optimal airflow and moisture control.

VI. Monitor and Adjust for Environmental Factors

Understanding and adapting to environmental factors, such as temperature and humidity, can significantly improve desiccant performance. For instance, if your shipment is traveling through a region with high humidity levels, you may need to increase the amount of desiccant used or consider using a more absorbent product.

Similarly, if your cargo is sensitive to temperature changes, you may need to take additional precautions to insulate the container or control the temperature within it. Regularly monitoring the environmental conditions during transit and adjusting your moisture control strategy accordingly can help maximize the efficiency of your shipping container desiccants and ensure that your cargo remains protected.

VII. Regularly Inspect and Replace Desiccant Bags as Needed

Over time, desiccant bags can become saturated and lose their ability to absorb moisture effectively. To maintain optimal performance, it’s essential to inspect your desiccants regularly and replace them as needed. This is particularly important for long-term storage or shipments with extended transit times.

By routinely checking the condition of your desiccants and replacing them when necessary, you can ensure that they continue to provide effective moisture control and protect your cargo throughout its journey.

VIII. Educate Your Staff on Desiccant Best Practices

Proper desiccant use requires knowledge and understanding of moisture control techniques and best practices. Educating your staff on the importance of desiccants and how to use them effectively can help prevent costly mistakes and ensure that your cargo remains protected against moisture damage.

Consider providing training sessions or workshops for your employees, covering topics such as proper desiccant selection, placement, and monitoring. By empowering your staff with the knowledge they need to use desiccants effectively, you can create a culture of proactive moisture control within your organization.

IX. Conclusion: Protect Your Cargo with Confidence

By following these seven tips, you can maximize the efficiency of your shipping container desiccants and safeguard your valuable cargo against moisture-related damage. Through proper desiccant selection, placement, monitoring, and staff education, you can confidently protect your shipments and ensure their safe arrival at their destination.

X. Frequently Asked Questions (FAQ)

What is the primary purpose of a shipping container desiccant?

Shipping container desiccants are designed to absorb moisture in the air within a container, thereby preventing humidity-related damage to the cargo. By controlling the humidity level, desiccants help protect goods from issues such as mold, mildew, corrosion, and other moisture-related damages.

How do I choose the right type of desiccant for my shipment?

When choosing a desiccant, consider factors such as the type of cargo, shipping duration, and environmental conditions during transit. Some desiccants are more absorbent and suitable for sensitive cargo, while others may be more eco-friendly. Consult the manufacturer’s guidelines or seek expert advice to select the most appropriate desiccant for your specific needs.

How often should I inspect and replace my shipping container desiccants?

Regular inspections are crucial for maintaining the effectiveness of your desiccants. The frequency of inspections and replacements will depend on factors such as the desiccant type, shipping duration, and environmental conditions. For long-term storage or extended transit times, more frequent inspections and replacements may be necessary.

Can I reuse my shipping container desiccants?

Some desiccants are designed to be disposable and should not be reused. However, certain types of desiccants can be regenerated and reused, depending on the manufacturer’s guidelines. Always consult the product instructions to determine whether your desiccant is reusable or should be replaced after use.

How can I ensure that my staff is using desiccants effectively?

Educate your staff on the importance of desiccants and provide training on proper desiccant selection, placement, and monitoring. By empowering your employees with the knowledge and skills they need to use desiccants effectively, you can create a proactive moisture control culture within your organization and ensure that your cargo remains protected against moisture damage.

Top Industries That Benefit from Using Shipping Container Desiccants

A Container Desiccant Study on Temperature and Relative Humidity

https://www.sciencedirect.com/science/article/pii/S2666154322002113

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้