Molecular Sieves for Air Drying and Purification: Enhancing Air Quality and Equipment Longevity Across Industries

| Molecular sieves for air drying and purification | Key Takeaways |

|---|---|

| How Molecular Sieves Work in Air Drying | Molecular sieves selectively adsorb moisture from air, using their porous structure to trap water molecules. This makes them highly effective in maintaining dry air environments across various industrial applications. |

| Types of Molecular Sieves for Air Drying | Different molecular sieve types (4A, 13X) suit various applications. 4A sieves are excellent for general air drying, while 13X sieves are optimal for air purification processes in PSA systems due to their larger pore sizes. |

| Benefits for Compressed Air Drying Systems | Using molecular sieves in compressed air systems offers precise moisture control, extending equipment lifespan, improving efficiency, and reducing the risk of corrosion and contamination in sensitive applications. |

| Application in PSA Systems | Molecular sieves, especially 13X, enhance Pressure Swing Adsorption systems by purifying air, ensuring a high-purity output for industrial and medical applications. PSA systems benefit from their selective nitrogen and CO₂ adsorption. |

| Real-World Applications | Industries such as automotive, food processing, and healthcare rely on molecular sieves for moisture control and clean air. Their use in these settings protects equipment and maintains product quality and safety. |

Introduction

Molecular sieves for air drying and purification are integral to applications across industries, from manufacturing to healthcare. Their ability to adsorb moisture at the molecular level makes them indispensable in processes that require clean, dry air. By selectively trapping moisture, they prevent system corrosion, ensure equipment longevity, and maintain air quality standards essential for safe and efficient operations. Their usage spans compressed air systems and Pressure Swing Adsorption (PSA) technologies, both of which benefit from the moisture control that molecular sieves provide. Explore A Comprehensive Guide to Molecular Sieves

How Molecular Sieves Work in Air Drying

| Key Point | Details |

|---|---|

| Selective Adsorption | Molecular sieves adsorb moisture by trapping water molecules based on size, ensuring dry air output. |

| Efficiency in High Humidity | Maintain consistent drying efficiency, even in challenging, moisture-laden environments. |

| Ideal Structure | Uniform pore size allows precise moisture control, perfect for long-term air drying applications. |

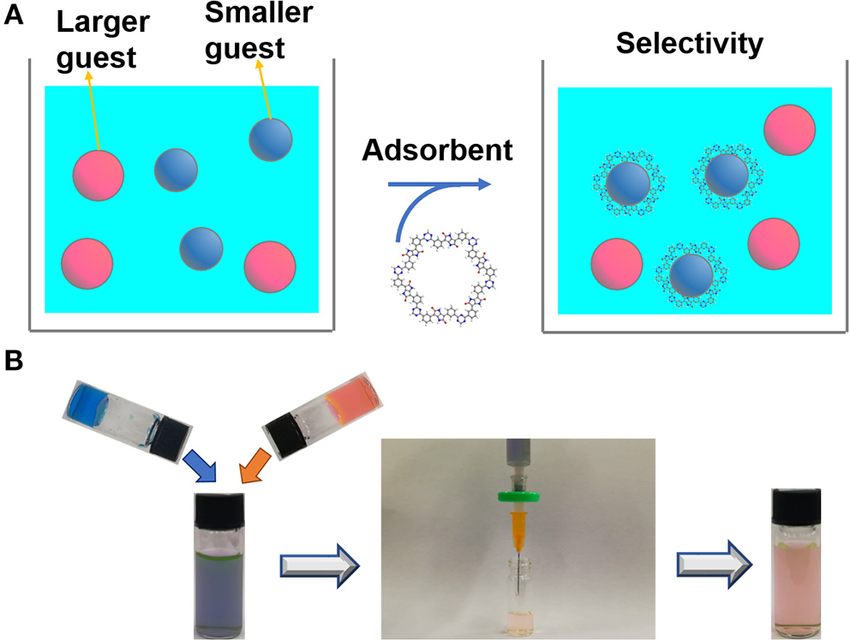

Molecular sieves operate through a unique process called selective adsorption, which allows them to precisely target and capture molecules of specific sizes. This is achieved thanks to their uniform, nanometer-sized pores that create a structure with strict molecular entry limits. In air drying applications, this means that only water molecules, which are small enough to fit through the sieve’s pores, are absorbed and trapped, effectively removing moisture from compressed air or industrial gas systems. This makes molecular sieves an exceptionally reliable desiccant in environments where controlling humidity is critical.

What sets molecular sieves apart from other desiccants is their efficiency and resilience in high-humidity conditions. While traditional drying agents like silica gel may lose efficacy over time or under intense humidity, molecular sieves retain their adsorption capacity across a range of environmental conditions. This long-lasting performance makes them ideal for applications that demand sustained moisture control, such as in compressed air drying or sensitive equipment that requires pristine air quality. By ensuring consistent moisture removal, molecular sieves help protect equipment from corrosion, contamination, and other issues related to excess humidity.

Types of Molecular Sieves for Air Drying

| Type | Application |

|---|---|

| 4A Molecular Sieve | General air drying; adsorbs water molecules effectively in compressed air systems. |

| 13X Molecular Sieve | Suitable for PSA systems, targets nitrogen and carbon dioxide while allowing purified oxygen to pass through. |

| Application Versatility | Different sieve types meet specific moisture and purification needs, tailored to each industrial use case. |

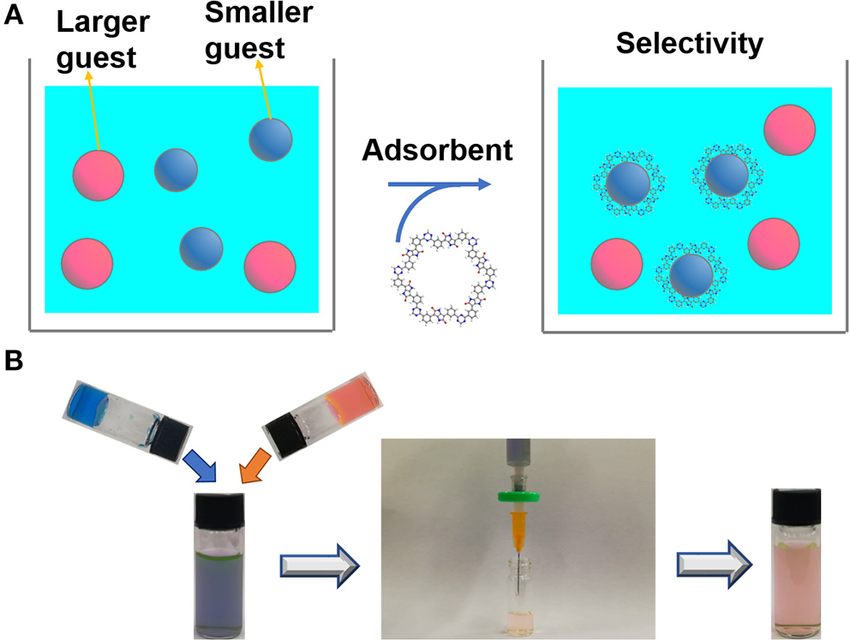

In air drying applications, selecting the right type of molecular sieve can make a significant difference in effectiveness. The 4A molecular sieve is a go-to choice for general air drying because its pore size is optimized to target water molecules exclusively. This allows for efficient moisture removal without affecting other gases, making it ideal for compressed air systems where consistent drying is essential to protect equipment and maintain air quality. The 4A sieve’s selective adsorption ensures high performance in industries where the primary goal is to remove humidity without any complex gas separation.

On the other hand, the 13X molecular sieve, with its larger pores, is specifically designed for applications requiring more comprehensive gas purification, such as Pressure Swing Adsorption (PSA) systems. This sieve can adsorb not only water but also larger molecules like carbon dioxide and some hydrocarbons, making it highly valuable in environments where both moisture control and gas purity are critical. In PSA systems, 13X molecular sieves enhance air purification by separating nitrogen from oxygen, which is essential in medical and industrial oxygen generation. These unique properties allow the 13X sieve to cater to complex drying and purification needs, supporting industries that demand both moisture-free and contaminant-free air.

Benefits for Compressed Air Drying Systems

| Benefit | Details |

|---|---|

| Corrosion Prevention | Protects components from moisture-induced corrosion, extending equipment life. |

| Efficiency Boost | Ensures equipment runs smoothly without moisture interference, enhancing system reliability. |

| Industry Applications | Essential in industries like food processing and automotive manufacturing, where clean, dry air is critical. |

In compressed air drying systems, moisture control is critical to prevent damage to sensitive equipment components. Excess moisture in compressed air can lead to corrosion, decrease equipment lifespan, and reduce operational efficiency. By adsorbing moisture before it reaches these components, molecular sieves protect systems, ensuring that equipment runs smoothly and efficiently. Industries where clean, dry air is essential—such as food processing, pharmaceuticals, and automotive manufacturing—benefit significantly from this technology.

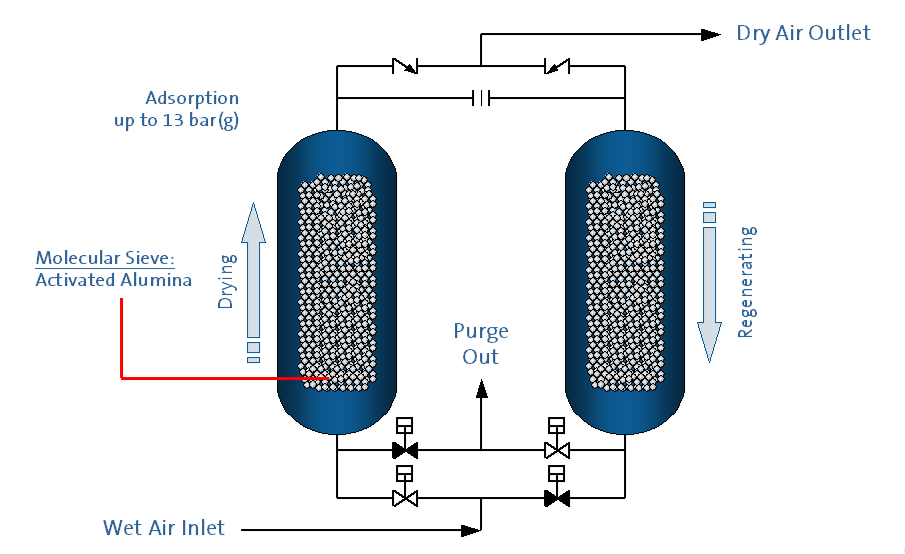

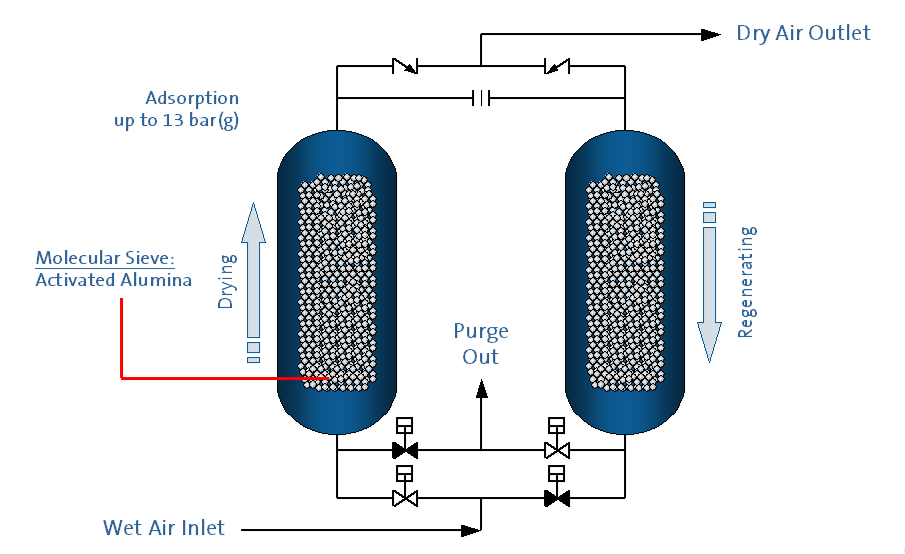

Adsorption Phase: Wet air enters from the bottom of the left tower, where the molecular sieve adsorbs moisture up to a specified pressure (up to 13 bar(g)), resulting in dry air exiting from the top.

Regeneration Phase: While one tower is drying, the other undergoes regeneration. Here, the moisture-saturated sieve releases the adsorbed water as pressure is reduced, allowing purge gas to flush out the water.

The towers alternate between these phases to ensure continuous drying, with one always adsorbing while the other regenerates. This setup enables efficient moisture control in high-demand applications like compressed air systems.

Molecular sieves excel in air drying applications due to their high adsorption capacity and durability, particularly in high-pressure environments like compressed air systems. These sieves maintain low moisture levels, making them ideal for applications that require a consistently dry environment. Their reliability under varying operational conditions ensures stable system performance, even in demanding industrial setups.

For a deeper look into the advantages of molecular sieves in air drying applications, explore The Benefits of Using Molecular Sieves in Gas Drying Applications. This resource offers insights into how molecular sieves contribute to system efficiency and longevity across various industries that depend on pure, moisture-free air.

Application in PSA Systems

| Key Function | Details |

|---|---|

| Gas Purification | Adsorbs nitrogen and carbon dioxide, allowing separation of pure oxygen in PSA systems. |

| Essential for Medical Use | Used in medical oxygen concentrators to ensure the delivery of high-purity oxygen. |

| Optimal Sieve Choice | 13X molecular sieves are best suited for PSA applications due to their selective adsorption capabilities. |

In Pressure Swing Adsorption (PSA) systems, molecular sieves are crucial for gas separation and purification, especially in applications demanding high-purity gases like medical oxygen. PSA systems utilize molecular sieves to selectively adsorb nitrogen and carbon dioxide, enabling the separation of oxygen or other target gases from the air. This process ensures that the output gas meets strict purity standards, a critical factor in healthcare and industrial settings.

Molecular sieves, such as 13X, are specifically optimized for PSA, ensuring efficient, continuous gas separation while maintaining stable system performance. Their unique structure allows them to selectively trap specific gases, which is essential for processes where gas purity and efficiency are priorities.

For further insights into how molecular sieves enhance gas purity across various industries, refer to Optimizing Gas Purity. This link offers detailed information on how molecular sieves improve the reliability and quality of PSA and other air purification systems.

Zeolites play an essential role in Pressure Swing Adsorption (PSA) systems, particularly for CO₂ removal and high-purity gas production. Their unique structure and adsorption properties allow them to selectively capture specific molecules under varying pressures, a capability central to effective air drying and purification processes. To dive deeper into how zeolites enhance adsorption capacity and support clean air systems, check out this study on Zeolites: Their Features as Pressure Swing Adsorbents and CO₂ Adsorption Capacity.

Real-World Applications

| Industry | Application |

|---|---|

| Healthcare | Air purification in medical breathing systems, ensuring safety and reliability. |

| Automotive | Moisture control in air systems, protecting vehicle components from corrosion. |

| Food Processing | Moisture control for product quality and extended shelf life in packaging and processing environments. |

Molecular sieves are crucial for air drying and purification across diverse industries, each with unique requirements for moisture control. In healthcare, molecular sieves purify air for breathing systems, ensuring patient and staff safety by maintaining clean, moisture-free air in respiratory equipment. This moisture control is vital in protecting sensitive medical components and supporting high standards of air purity for treatment areas.

In the automotive sector, molecular sieves play an essential role in air systems by preventing moisture buildup that could lead to corrosion. By keeping air systems dry, molecular sieves protect components, extending their lifespan and enhancing overall vehicle reliability. This is particularly valuable in air brake systems, where moisture-free air is critical for safety and performance.

In food processing, maintaining a controlled environment is essential for quality assurance. Molecular sieves prevent excess moisture in packaging and storage, which helps preserve product integrity and extend shelf life. By controlling humidity levels, these sieves contribute to the consistency and freshness of products, from baked goods to packaged snacks.

The versatility of molecular sieves in applications like air drying demonstrates their necessity across industries requiring precise moisture control. In industrial settings, such as sulfonation, moisture management can impact product quality and operational efficiency. For a focused look at their role in maintaining moisture control, refer to Achieving the Perfect Dry: Air Drying in Sulfonation.

Innovations and Future Directions

| Innovation Area | Details |

|---|---|

| Enhanced Durability | New molecular sieve materials are designed to withstand longer usage without degradation. |

| Improved Adsorption | Increased capacity for moisture and impurity adsorption for greater air purity. |

| Sustainability Focus | Advances aimed at creating eco-friendly, energy-efficient molecular sieves for broader industrial use. |

As industries increasingly prioritize air purity and effective moisture control, molecular sieve technology continues to advance. Innovations are focused on boosting the durability and adsorption efficiency of molecular sieves, making them more adaptable to today’s air purification requirements. By improving regeneration capabilities and reducing environmental impact, these enhancements support sustainable practices, enabling molecular sieves to play a crucial role in eco-friendly industrial applications. Future developments in this technology are set to offer even greater energy efficiency, aligning with the demand for clean, dry air across diverse sectors.

Frequently Asked Questions

What are molecular sieves in air drying applications?

Molecular sieves are desiccants used in compressed air drying to adsorb moisture, ensuring a stable and dry air supply across various applications.

How do molecular sieves function in moisture control?

They function through selective adsorption, where their pore sizes capture water molecules, effectively controlling moisture levels in air systems.

Why is moisture control important in compressed air systems?

Moisture in compressed air can lead to corrosion, equipment degradation, and reduced efficiency. Molecular sieves prevent these issues by adsorbing excess water.

What types of molecular sieves are used in air drying?

Common types include 4A and 13X sieves. The 4A type is ideal for general moisture removal, while 13X is suited for more intensive air purification, including gas separation in PSA systems.

How do molecular sieves support PSA systems?

In PSA systems, molecular sieves selectively adsorb gases like nitrogen, enabling the separation and purification of oxygen for clean air applications.

What is the benefit of molecular sieves in industrial applications?

They provide efficient moisture adsorption and air purification, enhancing equipment protection and system longevity across various industries.

Are molecular sieves reusable in air drying applications?

Yes, molecular sieves can be regenerated and reused, which makes them cost-effective and environmentally friendly over time.

What role do molecular sieves play in air purification?

They help remove impurities like moisture, CO₂, and nitrogen, ensuring high-quality, contaminant-free air in clean air systems.

How do molecular sieves impact equipment protection?

By controlling moisture and contaminants, they protect sensitive equipment from corrosion and wear, extending operational life.

Are molecular sieves efficient in high-humidity environments?

Yes, their high adsorption capacity allows them to perform reliably even in high-humidity conditions, maintaining consistent moisture control.

How does desiccant technology compare to molecular sieves in air drying?

Molecular sieves are a type of desiccant with superior adsorption properties, ideal for specific industrial applications requiring ultra-dry air.

What are clean air systems, and how do molecular sieves contribute?

Clean air systems require purified, dry air for optimal operation. Molecular sieves ensure these systems maintain high air quality standards.

How are molecular sieves integrated into compressed air drying?

They are often included in drying units within compressed air systems, where they adsorb moisture before it can reach sensitive components.

Why is molecular sieve regeneration important?

Regeneration restores the sieve’s adsorption capacity, making it possible to reuse the desiccant and maintain its efficiency.

What industries benefit from molecular sieves in air drying?

Industries like healthcare, food processing, automotive, and manufacturing benefit greatly from air drying and purification with molecular sieves.

Can molecular sieves be used for moisture adsorption in HVAC systems?

Yes, they are commonly used to control moisture in HVAC systems, enhancing air quality and preventing system degradation.

How does molecular sieve adsorption technology enhance air quality?

By selectively adsorbing impurities and moisture, molecular sieves improve air quality, essential for processes that require ultra-pure air.

What is the difference between 4A and 13X molecular sieves?

The 4A sieve has smaller pores, ideal for moisture adsorption, while the 13X sieve has larger pores, making it suitable for both moisture and gas purification.

Do molecular sieves require special handling or storage?

Yes, to maintain effectiveness, they should be stored in dry conditions, as exposure to ambient moisture can impact their adsorption capacity.

What maintenance considerations are needed for molecular sieves?

Regular regeneration and occasional performance testing help maintain their adsorption efficiency and prolong their service life.

Conclusion

Molecular sieves for air drying and purification play a pivotal role in industrial processes that require clean, moisture-free air. Their ability to selectively adsorb moisture and impurities makes them indispensable in sectors ranging from healthcare to automotive manufacturing. By enhancing system reliability, extending equipment life, and maintaining air quality standards, molecular sieves contribute significantly to operational efficiency and safety. As technology advances, molecular sieves will continue to evolve, supporting sustainable air management solutions.

To ensure the highest efficiency in moisture removal and air drying, industries increasingly leverage the advanced adsorption capabilities of molecular sieves. In applications requiring ultra-dry, contaminant-free air, these sieves outperform other drying methods by selectively adsorbing moisture and gases like CO₂. This is particularly relevant in sectors using high-pressure systems, where impurities can degrade equipment and processes. For more technical insights into the role of molecular sieves in gas drying, explore this comprehensive guide: The Benefits of Using Molecular Sieves in Gas Drying Applications.

Ready to elevate the efficiency of your air drying and purification systems? Explore our full range of molecular sieves designed for optimal moisture control and clean air applications. Visit our Molecular Sieve category to find the ideal solution tailored to your industry’s needs!

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้