Molecular Sieves for Carbon Capture and Environmental Applications

| Molecular Sieves for Carbon Capture | Description |

|---|---|

| Primary Function | Selective adsorption of gases like CO₂, moisture, and impurities to enhance environmental sustainability |

| Applications | Carbon capture, emission control, biogas purification, industrial gas separation, automotive exhaust systems |

| Primary Types for CO₂ Capture | 13X molecular sieves, MSOX-500, MSOX-501 |

| Environmental Impact | Reduces greenhouse gas emissions, supports eco-friendly filtration, helps achieve carbon footprint reduction. |

| Target Industries | Industrial gas, automotive, energy, healthcare, environmental sustainability |

| Technical Advantages | High adsorption capacity, resilience in various temperatures and pressures, eco-friendly filtration |

Table Of Contents

“Molecular sieves have become indispensable in emission control efforts, particularly in industries aiming to reduce their greenhouse gas output. Their selective adsorption capabilities allow for the capture of specific molecules, which is key to environmental sustainability efforts.”

The Role of Molecular Sieves in Environmental Sustainability

Molecular sieves are at the forefront of carbon capture and environmental applications. These unique materials, with their powerful ability to selectively adsorb gases like CO₂ and moisture, offer significant advantages for industries committed to reducing their carbon footprints. From biogas purification to emission control in automotive applications, molecular sieves play a pivotal role in supporting eco-friendly filtration and achieving real-world environmental sustainability.

The magic of molecular sieves lies in their engineered, highly porous structure, which captures unwanted molecules while allowing others to pass. This selectivity is the foundation of carbon reduction processes and emission control technologies that help industries meet increasingly stringent environmental standards. In this article, I’ll dive into the science and applications of molecular sieves, sharing practical insights for professionals across sectors like industrial gas, energy, and automotive.

What Are Molecular Sieves?

| Molecular Sieve Type | Primary Use | Pore Size | Key Applications | Benefits |

|---|---|---|---|---|

| Molecular Sieves 13X | CO₂ Capture | 9 Å | Carbon capture, emission control | High CO₂ adsorption, selective separation |

| Molecular Sieves 5A | Moisture & CO₂ Removal | 5 Å | Hydrogen purification, gas drying | Precise separation, durable in high pressure |

| Molecular Sieves 3A | Drying, minimal residual H₂O | 3 Å | Solvent drying, petrochemical moisture control | Minimal residual moisture, efficient drying |

| MSOX-500 / MSOX-501 | Oxygen Production | Variable | Industrial and medical oxygen generation | High purity oxygen, rapid adsorption |

At the most basic level, molecular sieves are advanced materials that operate like tiny filters with a specific “mesh size.” The structure of a molecular sieve is made up of uniform, crystalline pores that can trap molecules based on size and polarity. Zeolite-based molecular sieves, particularly types like Molecular Sieves 13X, are highly effective for CO₂ capture and greenhouse gas filtration because of their ability to selectively adsorb gases.

Imagine these sieves as high-tech sponges designed to soak up only the molecules we don’t want in our environments—like CO₂ in flue gases or moisture in fuel tanks. For carbon capture and environmental applications, the capacity and structure of these sieves are carefully chosen to maximize adsorption. The 13X molecular sieve, for example, is particularly prized for its 9-angstrom pore size, making it suitable for targeting CO₂ molecules in various emission control setups.

While Molecular Sieves 13X are widely favored for their high CO₂ adsorption capabilities, Molecular Sieves 5A offer unique benefits, especially in separating molecular mixtures and drying applications. Made with a smaller 5-angstrom pore size, 5A molecular sieves are optimized for capturing smaller molecules, enabling precise separations that are invaluable in industrial processes like hydrogen purification, gas drying, and even certain types of carbon capture.

Pressure Swing Adsorption (PSA) and Hydrogen Purification

One standout application for 5A molecular sieves is in pressure swing adsorption (PSA) systems, where they are used to separate hydrogen from CO₂ and other contaminants in mixed gas streams. In hydrogen production, particularly in sectors aiming for low-emission energy solutions, 5A sieves are essential for removing unwanted CO₂, moisture, and other gases, making the hydrogen output more pure and suitable for fuel-cell applications. This precision plays a crucial role in the growing hydrogen economy, where clean energy production aligns with broader carbon reduction goals.

CO₂ and Moisture Removal

5A molecular sieves also shine in applications requiring both CO₂ and water vapor removal. In petrochemical processing, for example, they are often used to dehydrate gases before they enter sensitive stages of production, ensuring product quality and equipment longevity. Their ability to adsorb moisture is especially valued in environments where even minimal water content can disrupt processes or corrode machinery. Similarly, in natural gas processing, 5A sieves help purify the gas by removing trace water and CO₂, thus enhancing both fuel quality and environmental safety standards.

Enhanced Stability in High-Pressure Environments

5A molecular sieves are built to withstand high-pressure and high-temperature environments, making them highly reliable in demanding industrial applications. Their resilience under extreme conditions makes them a suitable choice for sectors like petrochemicals and industrial gas, where consistent performance is essential to process efficiency and environmental compliance.

How Molecular Sieves Enable Carbon Capture and Emission Control

One of the standout applications of molecular sieves is in carbon capture technology, which is increasingly critical as industries face pressure to limit greenhouse gas emissions. In practical terms, these sieves work by trapping CO₂ and other greenhouse gases within their pores, effectively reducing their release into the atmosphere. Molecular sieves like the 13X have high CO₂ adsorption capacities and are often employed in pressure swing adsorption (PSA) systems—industrial setups designed to selectively capture and release gases.

In my experience, the adaptability of molecular sieves for emission control is one of their most compelling qualities. Industries can deploy these materials in various forms, from large-scale scrubbers in power plants to compact filters in automotive exhaust systems. The result is a versatile and highly effective solution for reducing harmful emissions. These sieves are not only essential for meeting regulatory requirements but are also powerful tools for businesses committed to long-term environmental sustainability.

Key Applications of Molecular Sieves in Environmental Sustainability

| Industry | Application | Molecular Sieve Type |

|---|---|---|

| Industrial Gas | CO₂ capture in flue gases | 13X, 5A |

| Automotive | Emission control, exhaust systems | 5A, 3A |

| Petrochemicals | Moisture removal, gas purification | 5A, 3A |

| Healthcare | Oxygen production | MSOX-500, MSOX-501 |

| Biogas Production | Biogas purification | 13X, 5A |

Molecular sieves bring value across multiple industries with applications that drive eco-friendly outcomes. Here are some of the primary ways they are employed to advance carbon capture and environmental sustainability:

Biogas Purification

Biogas purification is a vital process for transforming raw biogas into a cleaner, more efficient fuel source. Here, molecular sieves are used to remove impurities like CO₂, H₂S, and moisture from biogas, resulting in a more refined product. In my work with biogas facilities, I’ve seen how 13X molecular sieves enhance biogas quality, allowing it to meet fuel-grade standards. This eco-friendly filtration process is crucial for turning waste products into renewable energy while minimizing carbon footprints.

Emission Reduction in Manufacturing

Manufacturing facilities often emit volatile organic compounds (VOCs) and CO₂ as by-products. Molecular sieves can effectively capture these emissions, especially in high-temperature environments where other materials might fail. For instance, in a facility producing chemicals or electronics, the sieves trap harmful gases before they escape into the environment, helping the industry meet emission control targets. The specific properties of 13X and MSOX sieves make them resilient and efficient in these settings, capturing greenhouse gases even under fluctuating conditions.

Automotive Emissions Control

The automotive sector relies on molecular sieves within catalytic converters and exhaust systems to reduce air pollution. In particular, the ability of molecular sieves to adsorb NOx and CO₂ means they are an excellent choice for managing vehicle emissions. As car manufacturers strive to create eco-friendlier vehicles, these sieves play an increasingly important role in minimizing the environmental impact of transportation. Automotive engineers find sieves especially valuable for their durability and ability to withstand the high temperatures and pressures typical of exhaust systems.

Greenhouse Gas Capture

Molecular sieves have also found their place in large-scale greenhouse gas capture projects. These projects aim to trap CO₂ emissions from industrial sources, preventing them from contributing to global warming. With their high adsorption capacity and selectivity, molecular sieves like 13X are indispensable for these initiatives. Companies in energy-intensive industries, like steel and cement manufacturing, use these sieves to capture and store CO₂ before it enters the atmosphere. In the coming years, I foresee a growing reliance on molecular sieves to meet ambitious climate goals across multiple sectors.

Molecular sieves like Molecular Sieves 13X are indispensable in large-scale CO₂ sequestration efforts, aiding climate change mitigation across energy-intensive industries. For those interested in the broader environmental and industrial impacts of zeolites, this review of natural zeolites and their applications provides additional insights.

Advanced Molecular Sieve Modifications for Enhanced Carbon Capture

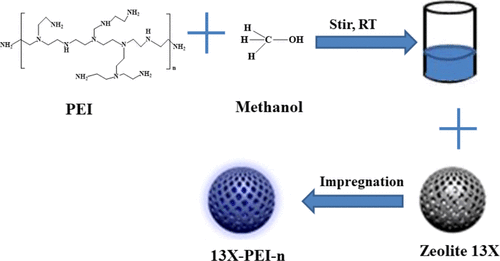

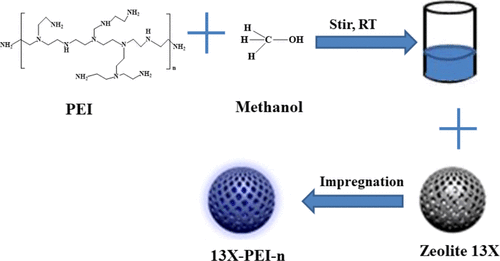

In the world of molecular sieves, advancements don’t stop at traditional materials like 13X zeolite. For carbon capture applications, where efficiency and selectivity for CO₂ are paramount, scientists and engineers have developed ways to modify molecular sieves to make them even more effective. One such innovation involves the impregnation of molecular sieves with amine-based compounds, such as polyethylenimine (PEI), to create an enhanced adsorbent material with a higher affinity for CO₂.

The Impregnation Process: Creating 13X-PEI

As shown in the diagram, the process to create 13X-PEI begins with mixing polyethylenimine (PEI) and methanol at room temperature to form a homogeneous solution. Zeolite 13X is then added to this solution, and through a process known as “impregnation,” the PEI molecules are infused into the pores and onto the surface of the zeolite. This treatment yields a composite material (13X-PEI-n) with an increased concentration of amine functional groups.

This modification is transformative because:

- Increased Selectivity: The amine groups on PEI have a strong affinity for CO₂, enabling the 13X-PEI composite to capture CO₂ molecules more selectively than unmodified zeolite 13X.

- Higher Adsorption Capacity: The addition of PEI significantly raises the CO₂ adsorption capacity of the zeolite, making it suitable for applications that require high CO₂ uptake, such as industrial carbon capture from flue gases.

- Enhanced Performance at Lower Pressures: Modified zeolites like 13X-PEI can perform well at lower pressures, which is beneficial in systems where pressurization is costly or impractical.

Real-World Applications of 13X-PEI in Carbon Capture

This type of modified molecular sieve is particularly beneficial in industrial settings where CO₂ needs to be separated from other gases efficiently and economically. Examples include:

- Flue Gas Treatment in Power Plants: In power generation, 13X-PEI composites are utilized to capture CO₂ from the flue gases emitted during fossil fuel combustion. By using amine-functionalized sieves, power plants can capture and remove significant amounts of CO₂ before it is released into the atmosphere, contributing to carbon reduction goals.

- Direct Air Capture (DAC): Given their enhanced selectivity and capacity for CO₂, amine-modified zeolites are also considered for direct air capture systems. These systems, designed to remove CO₂ directly from ambient air, can benefit from the high CO₂ affinity of 13X-PEI, which allows for efficient capture even in low-CO₂ concentrations.

- Biogas Purification: 13X-PEI molecular sieves are ideal for biogas facilities, where they can selectively remove CO₂ from biogas streams, resulting in a purified methane-rich gas that is suitable for use as a renewable fuel.

Pushing Boundaries in CO₂ Capture Technology

The modification of molecular sieves with compounds like PEI represents a significant leap forward in CO₂ capture technology. By increasing the selectivity and adsorption capacity of materials like zeolite 13X, we can optimize carbon capture processes across various industries. As environmental regulations tighten and companies seek more sustainable operations, these enhanced molecular sieves are invaluable tools in reducing greenhouse gas emissions and contributing to environmental sustainability.

Technical Insights: Adsorption Capacities, Pore Sizes, and Resilience

| Property | 13X Molecular Sieve | 5A Molecular Sieve |

|---|---|---|

| Pore Size | 9 Å | 5 Å |

| CO₂ Adsorption | ≥ 18% at 250 mmHg, 25°C | Varies, high moisture & CO₂ affinity |

| Temperature Range | -100°C to 200°C | -50°C to 250°C |

| Bulk Density | ≥ 0.62 g/ml | ≥ 0.68 g/ml |

| Primary Usage | CO₂ capture, gas separation | Moisture removal, PSA systems |

The technical strengths of molecular sieves—such as their adsorption capacity, pore size, and resilience—are what make them ideal for carbon capture and emission control.

Pore Sizes

The pore size of a molecular sieve determines which molecules it can capture. In CO₂ capture applications, the 13X molecular sieve’s 9-angstrom pore size is especially advantageous because it selectively adsorbs CO₂ molecules while letting smaller molecules, like nitrogen, pass through. This precise sizing allows molecular sieves to efficiently separate gases in complex mixtures, a capability central to PSA systems used in many industrial applications.

Adsorption Capacity

For effective carbon capture, a sieve’s adsorption capacity is a top priority. Molecular sieves designed for CO₂ applications, like the 13X, are tested under specific conditions to ensure high capacity for adsorbing CO₂. The MSOX-500 and MSOX-501 sieves, for instance, are engineered to withstand prolonged usage while maintaining superior adsorption rates, a necessity for continuous operation in systems such as PSA oxygen generators.

Temperature and Pressure Resilience

Industrial environments are often harsh, with fluctuating temperatures and high pressures. Molecular sieves designed for CO₂ and greenhouse gas capture must withstand these conditions without losing efficiency. The sieves we recommend are rigorously tested to confirm their stability in extreme conditions, ensuring they remain functional across diverse industrial applications. Their resilience allows them to continue adsorbing gases effectively, even when the system faces challenging operational demands.

Choosing the Right Molecular Sieve for Your Application

| Molecular Sieve | CO₂ Adsorption | Moisture Adsorption | Suitability for CO₂ Capture | Applications |

|---|---|---|---|---|

| 13X | High | Moderate | Excellent | Carbon capture, biogas upgrading |

| 5A | Moderate | High | Suitable | Hydrogen purification, gas drying |

| 3A | Low | Very High | Low | Petrochemical drying |

| MSOX-500/501 | High | Moderate | Specialized | Oxygen production |

Selecting the appropriate molecular sieve is essential for optimal performance in environmental applications. The type of sieve chosen should depend on the target gases, operational environment, and desired purity levels.

Guidance for Professionals

Professionals in the field often ask for recommendations on which sieve type to use for CO₂ capture. The 13X molecular sieve is typically the go-to choice for CO₂ and greenhouse gas applications because of its high adsorption capacity and targeted pore size. For oxygen generation, we might suggest MSOX-500 or MSOX-501, which are designed for PSA oxygen systems and portable oxygen generators. Understanding these specific attributes enables a more tailored approach to implementing molecular sieves effectively.

Example Use Cases

In industrial gas separation, 13X molecular sieves are preferred for their efficient CO₂ removal capabilities, as seen in facilities processing natural gas. Similarly, the 3A and 5A sieves are valuable for moisture removal in petrochemical processing, where they contribute to product quality and operational efficiency. Each application has unique requirements, and molecular sieves provide a range of solutions adaptable to various environmental and industrial demands.

Real-World Case Studies: Success Stories in Environmental Applications

Industrial CO₂ Capture

One notable case study involves a manufacturing plant that reduced its CO₂ emissions by integrating molecular sieves into its emission control systems. By using 13X sieves, the facility was able to capture and store CO₂, lowering its carbon footprint significantly and aligning with government-mandated emission limits. This successful application demonstrates how molecular sieves can drive substantial environmental progress in industrial settings.

Biogas Upgrading Facility

In biogas production, molecular sieves are crucial for upgrading raw biogas to fuel-grade quality. A biogas facility using 13X sieves was able to remove contaminants like CO₂ and H₂S, producing cleaner energy and reducing its reliance on fossil fuels. This case highlights the role of molecular sieves in promoting renewable energy sources and environmental sustainability.

Automotive Sector

The automotive industry has made strides in reducing emissions with the help of molecular sieves. For instance, a major car manufacturer incorporated sieves in its exhaust systems, effectively capturing CO₂ and reducing vehicle emissions. This application reflects the expanding role of molecular sieves in sectors beyond traditional industrial settings.

Frequently Asked Questions

What are molecular sieves, and how do they work in carbon capture?

Molecular sieves are materials with precise, uniform pores that can trap specific molecules based on size and shape. In carbon capture, they selectively adsorb CO₂ from gas mixtures, capturing it before it can enter the atmosphere.

How do molecular sieves contribute to CO₂ capture and carbon reduction?

By capturing CO₂ in industrial settings, molecular sieves reduce the volume of greenhouse gases released. This process directly contributes to carbon reduction efforts, helping industries lower their overall carbon footprint.

Why are 13X molecular sieves commonly used in CO₂ capture applications?

13X molecular sieves have larger pore sizes (9 Å), making them particularly effective for adsorbing CO₂ molecules. They also have high adsorption capacities, which is crucial for effective CO₂ capture in industrial processes.

Can molecular sieves be used in biogas purification?

Yes, molecular sieves are widely used in biogas purification. They help remove impurities like CO₂ and H₂S from raw biogas, upgrading it to fuel-grade quality for use as a renewable energy source.

What’s the difference between 13X and 5A molecular sieves in environmental applications?

13X molecular sieves are preferred for CO₂ capture due to their larger pore size, while 5A molecular sieves are used for moisture removal and separation of smaller molecules like nitrogen. Both types are valuable in emission control and carbon capture setups.

How do molecular sieves support environmental sustainability?

Molecular sieves enable cleaner industrial processes by reducing emissions, capturing greenhouse gases, and purifying biogas. These functions support environmental sustainability by minimizing pollution and enhancing renewable energy production.

Are molecular sieves reusable in carbon capture systems?

Yes, molecular sieves are often reusable. They can be regenerated through heating or pressure cycling to release the captured CO₂, making them a cost-effective and sustainable choice in carbon capture systems.

What industries commonly use molecular sieves for emission control?

Industries like energy, petrochemicals, automotive, and industrial gas frequently use molecular sieves for emission control to capture CO₂, moisture, and VOCs, which reduces harmful emissions and complies with environmental regulations.

How do molecular sieves impact a company’s carbon footprint?

By capturing CO₂ and other emissions, molecular sieves help companies reduce their carbon footprint. This technology allows industries to meet environmental standards and align with carbon reduction goals.

Can molecular sieves be used for eco-friendly filtration in other applications?

Yes, molecular sieves are used in eco-friendly filtration systems beyond carbon capture, such as air purification, water treatment, and solvent drying. They help remove pollutants and impurities, contributing to cleaner, safer environments.

What’s the role of molecular sieves in greenhouse gas capture?

Molecular sieves are instrumental in greenhouse gas capture due to their ability to selectively adsorb gases like CO₂. This process prevents these gases from entering the atmosphere, reducing the overall impact on climate change.

Are there limitations to using molecular sieves in carbon capture?

One limitation is that molecular sieves need to be regenerated periodically, which may require energy. Additionally, they are typically most effective at high purity levels, making them less efficient for low-concentration CO₂ capture without specialized systems.

What are the advantages of using 5A molecular sieves in environmental applications?

5A molecular sieves excel at moisture removal and gas separation, which are essential in applications like biogas upgrading and PSA hydrogen purification. Their precision in trapping smaller molecules enhances the purity of the output gases.

How do molecular sieves contribute to emission control in the automotive industry?

In automotive applications, molecular sieves help reduce emissions by adsorbing pollutants in catalytic converters and exhaust systems, contributing to cleaner air and helping manufacturers meet emissions standards.

Can molecular sieves improve the efficiency of renewable energy production?

Yes, molecular sieves can enhance renewable energy efficiency by purifying biogas and improving hydrogen fuel purity. Their role in upgrading biogas to fuel quality supports the transition to cleaner energy sources.

How long do molecular sieves last in carbon capture systems?

The lifespan of molecular sieves varies depending on usage and regeneration frequency. When properly maintained, they can last several years, providing effective CO₂ capture over extended periods.

Why are molecular sieves important for biogas purification?

In biogas purification, molecular sieves remove impurities like CO₂ and H₂S, enhancing the biogas quality. This process is essential for producing clean, usable fuel and reduces greenhouse gas emissions from raw biogas sources.

Can molecular sieves help meet strict environmental regulations?

Yes, molecular sieves support compliance with environmental regulations by capturing CO₂ and other pollutants. This ability to control emissions helps companies meet regulatory requirements for air quality and greenhouse gas limits.

Are there specific conditions where molecular sieves work best in carbon capture?

Molecular sieves perform optimally at controlled temperatures and pressures, often within PSA systems. They work best in conditions where CO₂ concentrations are high, as these setups maximize adsorption efficiency.

Where can I learn more about molecular sieves for carbon capture and environmental applications?

For an in-depth guide, refer to A Comprehensive Guide to Molecular Sieves, where you’ll find more on their types, applications, and specific benefits for environmental sustainability.

“By utilizing molecular sieves in our biogas upgrading facility, we were able to meet stringent fuel-grade standards while significantly reducing impurities. This process supports renewable energy initiatives and a lower carbon footprint.”

Conclusion: The Future of Molecular Sieves in Environmental Sustainability

The use of molecular sieves for carbon capture and environmental applications continues to grow as industries strive to meet sustainability goals. These materials are indispensable for CO₂ capture, biogas purification

, and emission control, offering real solutions to some of the world’s most pressing environmental challenges. By investing in molecular sieve technology, industries can make meaningful contributions toward a cleaner, greener future.

For more insights, explore A Comprehensive Guide to Molecular Sieves. If you’re ready to enhance your operations with molecular sieves, check out our Molecular Sieve Product Page. See also our page on the Environmental Impact of Molecular Sieves and Molecular Sieves in Green Energy Production.

Disclaimer

This article is for informational purposes only. While we strive to provide accurate and up-to-date information, SSE makes no warranties, express or implied, regarding the use of molecular sieves for specific applications. For tailored advice, please consult an expert.

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้