The Essential Role of Oxygen Absorbers: Reducing Oxidation Damage in Shipping

Table of Contents

In the shipping industry, one of the key challenges faced by businesses is the oxidation damage caused during transit and storage. This unseen issue can significantly affect the integrity and quality of the products, leading to increased costs and decreased customer satisfaction. Let’s explore how oxygen absorbers can mitigate these issues and preserve the quality of your goods.

The Concept of Oxidation Damage

Before diving into the solutions, let’s first understand what oxidation damage is and how it affects shipped goods. Oxidation is a chemical reaction that occurs when a substance comes into contact with oxygen. This process can lead to damage or spoilage in a variety of goods, especially those that are organic or metal-based. Oxidation can cause foods to spoil, electronics to malfunction, and metals to rust or tarnish.

What is Oxidation Damage?

In the context of shipping, oxidation damage refers to the harmful effects that oxygen can have on the products during transit and storage. This could include spoilage of food items, corrosion of metal parts, degradation of pharmaceuticals, and even discoloration of artwork.

How does it Affect Shipped Goods?

The impact of oxidation damage on shipped goods can be severe. For perishable items, it can lead to spoilage and loss of freshness, thereby affecting the quality and shelf life of the product. For non-perishable items like electronics and metal parts, oxidation can cause functional defects and physical damage, leading to reduced product lifespan and increased return rates.

The Importance of Preventing Oxidation in Shipping

Preventing oxidation damage in shipping is critical not only to maintain product quality but also to avoid unnecessary costs. The impact of oxidation on the product quality can lead to unsatisfied customers, product returns, and even damage to the company’s reputation.

The Impact on Product Quality

When products arrive in poor condition due to oxidation damage, it not only disappoints the customer but also reflects poorly on the company’s image. Moreover, if the products are intended for resale, their market value can significantly decrease due to inferior quality.

The Financial Implications of Oxidation Damage

The financial implications of oxidation damage can be substantial. Businesses may need to absorb the cost of returned goods, reimburse customers, or even recall products in severe cases. By preventing oxidation damage, companies can avoid these unnecessary costs and improve their bottom line.

An Introduction to Oxygen Absorbers

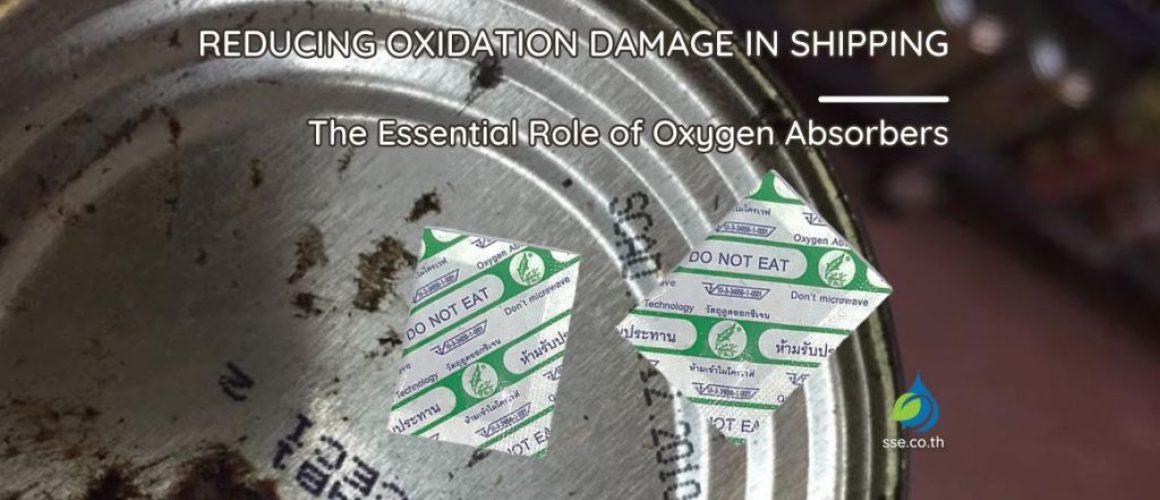

Oxygen absorbers, also known as oxygen scavengers or deoxidizer packets, provide an effective solution to this issue. These small packets are designed to absorb oxygen in closed environments, thereby preventing oxidation damage.

What are Oxygen Absorbers?

Oxygen absorbers are small packets containing iron powder, which effectively removes oxygen from the surrounding environment through a chemical reaction. They are commonly used in the packaging of a variety of goods, from food items to electronic components. You can find more about the science behind oxygen absorbers in our ultimate guide.

How do Oxygen Absorbers Work?

When an oxygen absorber packet is exposed to oxygen, the iron powder inside the packet reacts with the oxygen to form iron oxide, effectively removing the oxygen from the surrounding environment. This process helps to maintain the freshness and extend the product life by slowing down the oxidation process. Read more about how oxygen absorbers help maintain freshness and extend product life in our dedicated article.

The Role of Oxygen Absorbers in Reducing Oxidation Damage

Oxygen absorbers play a critical role in reducing oxidation damage during shipping by

removing oxygen within the packaging. This is especially beneficial for products that are sensitive to oxygen, such as food items, pharmaceuticals, and certain types of metals.

Oxygen Absorbers and Oxidation Control

By removing oxygen, oxygen absorbers can significantly slow down the oxidation process, thereby preventing oxidation damage. This can help to preserve the quality and integrity of the products during shipping and storage.

Types of Goods Benefiting from Oxygen Absorbers

Almost any product that is sensitive to oxygen can benefit from the use of oxygen absorbers. This includes food items, pharmaceuticals, electronics, and even artworks. For instance, food items like dried meats, nuts, and spices can maintain their freshness and flavor for a longer period when packaged with oxygen absorbers. Similarly, pharmaceuticals can maintain their efficacy, and electronic parts can avoid oxidation damage.

How to Use Oxygen Absorbers in Shipping

The usage of oxygen absorbers in shipping is straightforward and can be easily incorporated into existing packaging processes. However, choosing the right type and size of oxygen absorbers is crucial to ensure their effectiveness.

Steps to Incorporate Oxygen Absorbers in Packaging

Incorporating oxygen absorbers into your packaging process is simple. Start by choosing the right size of oxygen absorber based on the volume of the package and the type of product. Once the product is packed, place the oxygen absorber inside the package before sealing it. The oxygen absorber will start to absorb the oxygen inside the package as soon as it is exposed to the air.

Choosing the Right Type and Size of Oxygen Absorbers

Choosing the right type and size of oxygen absorbers is crucial to ensure their effectiveness. The size of the oxygen absorber required depends on the volume of the package and the type of product. We offer a variety of oxygen absorbers, including 10 CC, 50 CC, 100 CC, 200 CC, and 300 CC to cater to different needs.

Case Study: Oxygen Absorbers in Action

Let’s look at a real-world example of how oxygen absorbers have been used in the shipping industry to reduce oxidation damage. A food manufacturer was experiencing issues with spoilage during transit, leading to a high rate of product returns and dissatisfaction among customers. After incorporating oxygen absorbers into their packaging process, they noticed a significant reduction in spoilage rates, leading to increased customer satisfaction and reduced costs.

Navigating Oxidation Challenges in Shipping: A Final Note

Oxidation damage in shipping can lead to significant losses, but with the strategic use of oxygen absorbers, businesses can mitigate these risks effectively. By understanding the importance of preventing oxidation damage and the role of oxygen absorbers in achieving this, companies can improve their product quality, customer satisfaction, and ultimately, their bottom line.

Ready to protect your goods from oxidation damage during shipping? Explore our range of oxygen absorbers and find the perfect fit for your needs.

FAQ Section

What is the purpose of oxygen absorbers?

The primary purpose of oxygen absorbers is to remove oxygen within sealed environments to prevent damage caused by oxidation. They are used to help maintain product quality during storage and shipping.

What are oxygen absorbers in active packaging?

In active packaging, oxygen absorbers are used to maintain product freshness by removing oxygen that could otherwise lead to spoilage or degradation of the product.

What is the use of oxygen absorbers in food packaging?

In food packaging, oxygen absorbers help to extend the shelf life of food products by slowing down the oxidation process that can cause spoilage, discoloration, and loss of nutrient value.

What is the effect of oxygen in packaging?

Oxygen in packaging can lead to oxidation, which can result in product spoilage, discoloration, rust, and other forms of damage, particularly in food and metal items.

Are oxygen absorbers necessary?

The necessity of oxygen absorbers depends on the product. For products prone to oxidation damage, such as food, pharmaceuticals, and certain types of metal, oxygen absorbers are often necessary to maintain product quality.

What are the disadvantages of oxygen absorbers?

While oxygen absorbers provide many benefits, they can sometimes lead to the product drying out, particularly in food items, if not used correctly.

What is the difference between silica and oxygen absorber?

Silica gel is a desiccant used to absorb moisture, while oxygen absorbers are used to absorb oxygen. They are used for different purposes in packaging.

How many oxygen absorbers in a bag?

The number of oxygen absorbers needed per bag depends on the volume of the bag and the type of product being stored. Each oxygen absorber has a specific oxygen absorption capacity, typically indicated by its size in CC.

What is in oxygen absorbers?

Oxygen absorbers usually contain iron powder which reacts with oxygen to form rust, thereby removing oxygen from the surrounding environment.

What are the benefits of reduced oxygen packaging?

Reduced oxygen packaging can help to extend product shelf life, maintain product quality, prevent the growth of aerobic organisms and bacteria, and reduce the risk of product spoilage.

Do oxygen absorbers create a vacuum?

Oxygen absorbers do not create a vacuum. They absorb oxygen, reducing the overall oxygen level in the packaging, but do not remove other gases or air.

What is the difference between oxygen and moisture absorbers?

Oxygen absorbers remove oxygen from the packaging environment, while moisture absorbers, or desiccants, absorb moisture to prevent humidity-induced damage.

How does oxygen affect food storage?

Oxygen can lead to spoilage in food storage by promoting the growth of bacteria and other aerobic organisms. It can also cause oxidation, leading to rancidity in fats and oils, and discoloration in certain foods.

Do oxygen absorbers expire?

Oxygen absorbers do not have a traditional expiration date. However, once the packaging is opened, they begin to absorb oxygen and will be ineffective if not used within a short period.

What happens if you use too many oxygen absorbers?

Using too many oxygen absorbers will not harm your product. It will simply absorb the oxygen more quickly, which might lead to over-drying in some cases.

Are oxygen absorbers flammable?

Oxygen absorbers are not flammable. However, the iron powder in them can react with oxygen to generate heat, but it’s not enough to cause a fire.

How many times can you reuse oxygen absorbers?

Oxygen absorbers are not reusable. Once they have absorbed their capacity of oxygen, they can no longer effectively absorb oxygen.

What happens if I microwave an oxygen absorber?

Microwaving an oxygen absorber is not recommended. The iron powder can spark and potentially cause a fire.

What is another name for oxygen absorbers?

Oxygen absorbers are also commonly referred to as oxygen scavengers or deoxidizers.

Can you put oxygen absorbers in flour?

Yes, oxygen absorbers can be used in flour to prevent the growth of bugs and extend the shelf life.

Do oxygen absorbers absorb CO2?

No, oxygen absorbers are designed to absorb oxygen. They do not absorb CO2 or other gases.

Read more

ดูดออกซิเจนในการบรรจุภัณฑ์อาหาร

บทบาทสำคัญของสารดูดออกซิเจนในการห่อแพ็คเกจสำหรับอาหารเสริมเพื่อสุขภาพ

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้