The Magic of Bleaching Earth: A Complete Guide 2024

| Topic | Key Information |

|---|---|

| Role of Bleaching Earth | Bleaching earth is used in the oil bleaching process to remove impurities, color, and heavy metals, ensuring oil purity and quality. |

| How Bleaching Earth Works | Bleaching earth works by adsorbing contaminants in oil using its porous structure, attracting unwanted substances. |

| Types of Bleaching Earth | There are natural and activated bleaching earth types, each suitable for different industrial applications. |

| Benefits of Bleaching Earth | It reduces oil color and impurities, extends oil shelf life, and decreases the need for harmful chemicals in oil production. |

| Environmental Impact | The use of bleaching earth helps minimize environmental impact as it can be regenerated and reused, reducing waste and conserving natural resources. |

| Choosing the Right Bleaching Earth | Selecting the appropriate type of bleaching earth for the specific oil type ensures optimal oil bleaching efficiency and improved oil quality. |

Table of Contents

Introduction: What is Bleaching Earth?

Bleaching Earth may sound like something magical, but it’s a powerful industrial tool used in oil refining to improve the quality and appearance of oils. It’s not just limited to oil refining either; its use extends to many industries, including cosmetics and lubricants. Bleaching earth plays an essential role in improving the quality of edible oils, removing impurities, and ensuring that oils are safe for consumption. It has been used for decades to ensure that the oils we consume and use daily are of the highest quality.

“Bleaching earth is more than just a filtration agent—it’s the key to unlocking the purest, most vibrant oils, ensuring that the oils we consume are of the highest quality.”

When talking about bleaching earth, it’s important to understand that its functionality lies in the simplicity of its structure. Composed primarily of activated clay (often bentonite), bleaching earth has an incredible capacity to absorb impurities. This makes it an indispensable part of industrial oil processing, where the purification and decolorization of oils are key.

For an in-depth look at how bleaching earth is used in food-related applications, check out การใช้ดินฟอกสีเพื่อฟอกน้ำมันพืช: ปลอดภัยและมีประสิทธิภาพสูงสุดในอุตสาหกรรมอาหาร.

How Does Bleaching Earth Work?

The magic of Bleaching Earth lies in its ability to adsorb impurities and decolorize oils, making it an essential tool in oil purification. The process it undergoes is known as adsorption, where the surface of the bleaching earth attracts and holds onto the unwanted substances within the oil, including pigments, metals, and other impurities.

At the heart of this process is the physical structure of the bleaching earth. Thanks to its porous nature, bentonite clay is particularly effective at capturing the minute particles that give oil a darker appearance or reduce its purity. When oil is filtered through bleaching earth, these impurities are left behind, resulting in clearer and higher-quality oil. This process is widely used in the production of edible oils, ensuring they meet high standards for color and purity.

Composition of Bleaching Earth

| Component | Percentage |

|---|---|

| Silica (SiO2) | 62-70% |

| Alumina (Al2O3) | 10-15% |

| Iron Oxide (Fe2O3) | 2-6% |

| Magnesia (MgO) | 2-3% |

| Lime (CaO) | 0.5-2% |

| Soda (Na2O) | 0.2-0.5% |

| Potash (K2O) | 0.2-0.5% |

| Water (H2O) | 8-12% |

Bleaching earth is primarily composed of montmorillonite, a type of clay mineral that has a unique structure and chemical properties. Montmorillonite has a layered structure, with a central layer of aluminum and magnesium ions surrounded by silica and oxygen atoms. This unique structure gives montmorillonite its high adsorption capacity, which allows it to trap and remove impurities from different materials.

Types of Bleaching Earth: Natural vs. Activated

Not all bleaching earth is created equal—there are differences between natural and activated types, each suited for specific applications. Natural bentonite clay is the raw form of bleaching earth, which works by adsorbing impurities. However, activated clay has been treated to increase its adsorptive power, making it even more effective at removing contaminants.

Types of Bleaching Earth

| Type | Description | Best Use |

|---|---|---|

| Natural Bentonite | Unmodified clay with natural adsorptive properties | Basic oil filtration and decolorizing |

| Activated Clay | Treated for enhanced adsorption | High-efficiency oil refining and purification |

Activated bleaching earth is especially popular in the food industry, where precision is key. For example, refining edible oils such as soybean, palm, and sunflower oil often requires the use of activated clay to achieve the desired level of purity. Natural clay, on the other hand, is often used in less demanding industrial processes, where basic filtration is sufficient.

Benefits of Bleaching Earth

Bleaching earth offers numerous benefits in various industrial processes. Some of these benefits include:

- High Adsorption Capacity: Bleaching earth has a high surface area and a unique structure that allows it to trap and remove impurities, contaminants, and color pigments from different materials.

- Cost-Effective: Bleaching earth is a cost-effective solution for removing impurities and contaminants from different materials. It is a natural and abundant material that can be easily sourced and processed.

- Environmentally Friendly: Bleaching earth is a natural material that is safe for the environment. It does not contain harmful chemicals or synthetic additives that can harm the environment.

Key Benefits of Using Bleaching Earth

| Benefit | Description |

|---|---|

| Improved Oil Clarity | Removes color and impurities for a clearer product |

| Extended Shelf Life | Removes contaminants that could lead to spoilage |

| Cost-Effective | Affordable method for industrial-scale oil purification |

Beyond decolorizing oils, bleaching earth offers multiple benefits, from improving texture to enhancing flavor. When applied in the industrial oil processing sector, it helps manufacturers produce oils that are more stable, flavorful, and free of unwanted odors. This is particularly important in food products, where consumers demand the highest quality.

In edible oil refining, the power of bleaching earth lies in its ability to transform crude oil into a clear, consumable product with extended shelf life.

Additionally, using bleaching earth is cost-effective. Despite its power as a filtration and purification agent, it is relatively inexpensive, making it a favorite in many industrial applications. It’s also environmentally friendly, as it can be disposed of safely or even recycled in certain applications.

These benefits make bleaching earth a popular choice in various industrial processes, including the refining of edible oils and fats, petrochemicals, and cosmetics.

Unlock more insights into how bleaching earth enhances product quality and performance in various industries by visiting Unlocking the Purifying Power of Bleaching Earth.

Applications of Bleaching Earth

Bleaching earth has numerous applications in different industries. Some of these applications include:

- Oil Refining: Bleaching earth is commonly used in the refining process of edible oils and fats. It helps to remove impurities, contaminants, and color pigments from the oil, resulting in a cleaner and clearer product.

- Petrochemicals: Bleaching earth is used in the refining process of petrochemicals such as diesel, gasoline, and lubricants. It helps to remove sulfur, nitrogen, and other impurities from the petrochemicals, resulting in a cleaner and higher quality product.

- Cosmetics: Bleaching earth is used in the manufacturing of cosmetics such as facial masks, cleansers, and scrubs. It helps to absorb excess oil, dirt, and impurities from the skin, resulting in a clearer and brighter complexion.

Applications of Bleaching Earth in Industries

| Industry | Application | Purpose |

|---|---|---|

| Edible Oil Refining | Removes impurities and decolorizes oil | Improves oil quality and shelf life |

| Cosmetics | Purifies cosmetic ingredients | Ensures product safety and purity |

| Biodiesel Production | Removes contaminants from biodiesel feedstocks | Enhances fuel quality |

The Role of Bleaching Earth in Edible Oil Refining

In edible oil refining, bleaching earth acts as a crucial filtration and decolorizing agent, ensuring the oil is clean and safe for consumption. By removing unwanted colorants, pigments, and contaminants, it helps oil manufacturers produce a product that meets both health standards and consumer preferences.

The use of bleaching earth in oil refining extends beyond simple color reduction. It also plays a key role in removing potentially harmful substances such as heavy metals and oxidation products, which could affect both the safety and shelf life of the oil. Without bleaching earth, edible oils would not be able to meet the stringent regulations that govern their production.

For insights into how BE195A transforms food-grade oil purification, check out our article on How BE195A Supports the Bleaching Earth Food Industry: From Purity to Profit. This guide dives into how BE195A enhances oil quality, supports sustainability, and boosts profitability for food oil producers.

The efficiency of bleaching earth in oil filtration cannot be understated. Learn more about its advantages in oil processing at ประโยชน์ของดินฟอกสีสำหรับกรองน้ำมัน and how it contributes to the purification of edible oils at How Bleaching Earth Contributes to the Purification of Edible Oils

Industrial Applications Beyond Edible Oil

While its role in edible oil is vital, bleaching earth is also widely used in industries such as cosmetics, lubricants, and biodiesel production. In cosmetics, bleaching earth helps purify ingredients, ensuring they are safe for use in skin care products. In the lubricant industry, it assists in the refinement of oils, improving their performance and lifespan.

Factors Influencing the Effectiveness of Bleaching Earth

| Factor | Impact on Efficiency | Recommended Practice |

|---|---|---|

| Oil Temperature | Affects adsorption capacity | Heat oil to the optimal temperature before adding bleaching earth |

| Dosage Amount | Too much or too little can affect results | Conduct trials to determine the optimal dosage |

| Contact Time | Short contact time can reduce adsorption | Allow sufficient time for bleaching earth to interact with oil |

In the world of biodiesel production, bleaching earth is an important player in removing impurities from feedstocks before they are processed into fuel. Its use in this sector highlights just how versatile this material can be across a range of industries, all of which rely on clean, pure oils for their final products.

For an in-depth exploration of how bleaching earth can enhance the quality of industrial oils, check out our detailed guide on How BE195A Bleaching Earth Improves Industrial Oil Treatment. This article covers the unique benefits of BE195A in purifying and stabilizing oils used across various industrial applications.

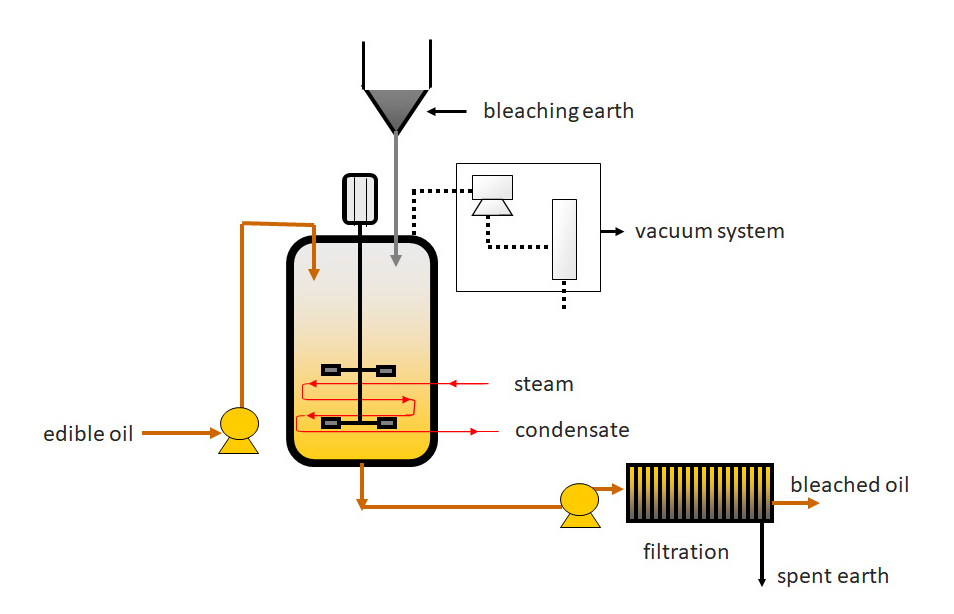

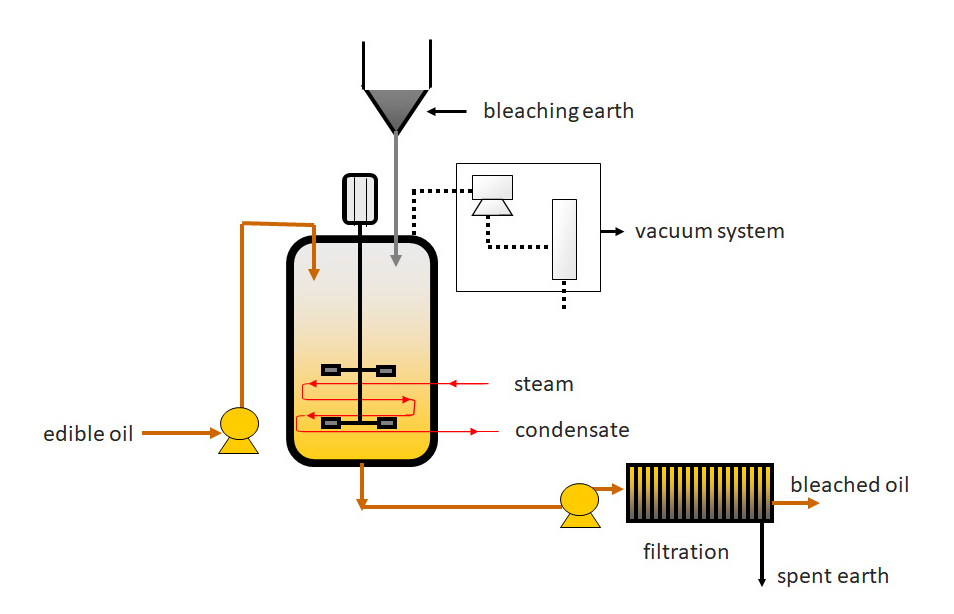

The Oil Bleaching Process: Step by Step

The oil bleaching process may sound complex, but it’s a straightforward series of steps that transform raw oil into a refined product. First, the crude oil is heated, and bleaching earth is added. The oil is then agitated, allowing the bleaching earth to adsorb impurities. After a set period, the oil is filtered to remove the used bleaching earth and any remaining contaminants.

Steps in the Oil Bleaching Process

| Step | Action | Outcome |

|---|---|---|

| Heating | The oil is heated to prepare for bleaching | Lowers oil viscosity for better filtration |

| Adding Bleaching Earth | Bleaching earth is mixed into the oil | Adsorbs impurities and unwanted colors |

| Filtration | The mixture is filtered to remove the bleaching earth | Results in clearer, more purified oil |

This step-by-step process ensures that the oil is not only visually appealing but also meets the highest standards for quality. In many oil refineries, this process is automated, allowing large quantities of oil to be processed efficiently and consistently.

For a deeper look into how BE195A can enhance oil clarity and quality through decolorization, check out our article on Achieving Optimal Oil Decolorization with BE195A Bleaching Earth. This guide covers everything you need to know about transforming oils through effective pigment removal.

Challenges in Using Bleaching Earth and How to Overcome Them

While bleaching earth is highly effective, there are some challenges in its use, such as selecting the right type and proper disposal. One of the most significant issues faced by manufacturers is ensuring that the bleaching earth used is compatible with the oil being processed. Different oils require different types of bleaching earth to achieve optimal results.

Challenges in Using Bleaching Earth

| Challenge | Description | Solution |

|---|---|---|

| Selection of Type | Choosing the correct type for specific oils | Test small batches with both natural and activated clays |

| Disposal Issues | Managing spent bleaching earth | Follow environmental guidelines for disposal |

Disposal of spent bleaching earth is another concern, as it can contain high levels of impurities. However, through proper management and waste disposal techniques, these challenges can be easily overcome. In some industries, spent bleaching earth is even recycled for use in other processes, reducing its environmental footprint.

From improving oil clarity to increasing shelf life, the applications of bleaching earth are vast. For more specialized uses, explore the articles on การใช้ดินฟอกสีเพื่อฟอกน้ำมันพืช and Unlocking the Purifying Power of Bleaching Earth.

Frequently Asked Questions

Is bleaching earth safe for human consumption?

Yes, bleaching earth is safe for human consumption. It is commonly used in the refining process of edible oils and fats and is approved by regulatory agencies such as the FDA.

Can bleaching earth be used in water treatment?

Yes, bleaching earth can be used in water treatment to remove impurities and contaminants from water. It has a high adsorption capacity and can help to purify water.

What is the difference between bleaching earth and activated carbon?

Bleaching earth and activated carbon are both adsorbents, but they have different properties and applications. Bleaching earth is primarily used in the refining process of oils, fats, and petrochemicals, while activated carbon is commonly used in water and air purification systems, as well as in the pharmaceutical and food industries.

How is bleaching earth sourced and processed?

Bleaching earth is sourced from natural deposits of clay minerals such as montmorillonite, bentonite, and attapulgite. The clay is mined and processed to remove impurities and contaminants, resulting in a pure and natural product.

Can bleaching earth be reused?

Yes, bleaching earth can be reused several times before it loses its adsorption capacity. The used bleaching earth can be regenerated by heating it to high temperatures, which removes the trapped impurities and restores its adsorption capacity.

Conclusion

Bleaching earth is a natural and versatile material that offers numerous benefits in various industrial processes. Its high adsorption capacity, cost-effectiveness, and environmental safety make it a popular choice in the refining of edible oils and fats, petrochemicals, and cosmetics. With its unique properties and applications, bleaching earth is truly a magic material that can transform different products and industries.

Bleaching earth has stood the test of time as an essential component in refining, and its future looks just as promising. As industries continue to innovate, new uses for bleaching earth are emerging, and advancements in activation processes are improving its efficiency.

From biodiesel to cosmetics, bleaching earth’s versatility proves indispensable across industries, ensuring purity and performance in every application.

Whether in edible oil refining or in industrial oil processing, the benefits of bleaching earth are undeniable. It plays a crucial role in ensuring that the products we use every day are of the highest quality. As environmental regulations tighten and demand for cleaner products grows, the role of bleaching earth will only become more important.

For those looking to explore the benefits of bleaching earth further, check out our detailed selection of Bleaching Earth products. Additionally, you can dive deeper into how bleaching earth purifies oils by visiting our previous post on How Bleaching Earth Contributes to the Purification of Edible Oils. For a comprehensive guide on the subject, refer to our cornerstone page, A Complete Guide to Bleaching Earth. Also, don’t miss our premium Activated Clay Bleaching Earth for optimal performance in oil purification.

For those seeking a high-performance solution, consider using Activated Clay Bleaching Earth 25kg to enhance oxidation processes and boost product quality.

For an in-depth look at how bleaching earth excels in sulfur removal, check out our latest guide on Effective Sulfur Filtration with Bleaching Earth.

Read more

How Bleaching Earth Contributes to the Purification of Edible Oils

Unlocking the Purifying Power of Bleaching Earth

ประโยชน์ของดินฟอกสีสำหรับกรองน้ำมัน

เร่งดินเหนียวฟอกสีใช้ทำน้ำมันอาหารได้อย่างปลอดภัยและมีประสิทธิภาพ

ดินเหนียวฟอกสี Bleaching Earth

External links

https://www.sciencedirect.com/science/article/pii/S2405844022021144

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้