Container Climatic Stresses and Their Impact on Container Handling

Container Climatic Stresses and Their Impact on Container Handling:

| Key Takeaway | Details |

|---|---|

| Definition of Climatic Stresses | Environmental conditions, such as temperature and humidity, affecting goods. |

| Impact on Goods | Can cause moisture damage, mold, corrosion, and packaging degradation. |

| Container Rain | Condensation inside containers that can harm goods. |

| Importance of Ventilation & Desiccants | Helps reduce moisture and regulate internal temperature to protect cargo. |

| Mitigating Climatic Stresses | Use desiccants, ventilation, and sensors to monitor and control conditions. |

Table of Contents

Container Handling: Climatic Stresses and Their Impact

The world of logistics and shipping is a complex one, with many factors to consider. One of the most crucial aspects that often gets overlooked is the impact of climatic stresses on container handling. This article aims to shed light on this topic, discussing the various climatic stresses that can affect containers and how to manage them effectively.

Understanding Container Climatic Stresses

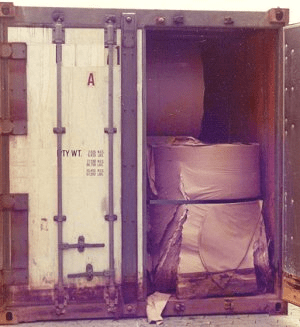

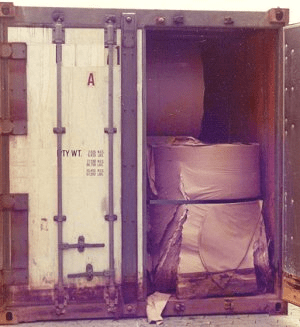

Container climatic stresses refer to the various weather conditions and environmental factors that can affect the condition of shipping containers and the goods within them. These include temperature fluctuations, humidity levels, and ventilation issues. Understanding these stresses is crucial for anyone involved in the shipping and logistics industry, as they can significantly impact the quality and safety of the transported goods.

Common Climatic Stresses in Shipping Containers

| Climatic Stress | Description | Impact on Goods |

|---|---|---|

| High Humidity | Moisture buildup inside the container | Mold growth, material degradation |

| Temperature Fluctuations | Changes in temperature causing condensation | Container rain, packaging damage |

| Poor Ventilation | Lack of airflow causing moisture accumulation | Increased moisture damage |

Understanding shipping container weather conditions is crucial as they directly affect the cryptoclimate inside the container. These weather conditions can range from extreme heat and cold to high humidity and heavy rainfall, each presenting unique challenges. For instance, high temperatures can lead to the expansion of air and materials inside the container, potentially damaging goods. On the other hand, extremely cold conditions can cause materials to contract and become brittle, leading to potential breakage.

Humidity levels are another critical factor in container climatic stresses. High humidity can lead to condensation inside the container, which can cause water damage to the goods. Conversely, low humidity can dry out certain goods, affecting their quality and usability.

Ventilation issues also play a significant role in container climatic stresses. Proper ventilation is necessary to maintain a balanced temperature and humidity level inside the container. However, inadequate ventilation can lead to a buildup of heat and moisture, leading to potential damage to the goods.

The key takeaway from this article is the critical role of managing climatic stresses in shipping containers. This includes controlling temperature, humidity, and ventilation to ensure the safety and quality of transported goods. Utilizing tools like sensors, ventilation systems, and desiccants can effectively mitigate these stresses.

Impact of Climate on Container Shipping

Climate plays a pivotal role in container shipping, with its effects being far-reaching and multifaceted. The weather conditions that a shipping container is exposed to during its journey can significantly influence the state of the goods inside. This is why understanding the impact of climate on container shipping is crucial for anyone involved in the logistics and supply chain industry.

Types of Goods Most Affected by Climatic Stresses

| Type of Goods | Primary Risk | Recommended Protection |

|---|---|---|

| Electronics | Corrosion, short-circuiting due to moisture | Use desiccants, sealed packaging |

| Food | Spoilage, mold | Ventilation, temperature control |

| Textiles | Mold, mildew | Desiccants, moisture barriers |

Extreme temperatures, both hot and cold, can cause substantial damage to the goods inside the containers. In hot climates, the internal temperature of the container can rise significantly, leading to potential heat damage. This is particularly concerning for temperature-sensitive goods such as food items, pharmaceuticals, and certain types of machinery. On the other hand, in extremely cold climates, goods can freeze or become brittle, leading to potential breakage or loss of quality.

The weather impact on container transport can be significant, affecting the condition of the container and the goods inside. It can lead to delays in shipping schedules, increased costs due to damage to goods, and even pose safety risks. Therefore, understanding and managing climate variations in shipping is crucial for the successful and efficient transportation of goods.

Container Climate Control: The Key to Safe Shipping

Effective container climate control is the cornerstone of safe and efficient shipping. It is the process of managing and maintaining the internal environment of a shipping container to ensure the safety and integrity of the goods inside. This involves controlling the temperature, humidity, and ventilation within the container to mitigate the impact of external climatic stresses.

Preventative Measures for Managing Climatic Stresses

| Preventative Measure | How It Works | Benefit |

|---|---|---|

| Desiccants | Absorbs excess moisture inside the container | Prevents container rain and mold growth |

| Ventilation Systems | Circulates air to maintain consistent airflow | Reduces moisture buildup and condensation |

| Temperature Control | Keeps internal temperature stable | Prevents temperature fluctuations |

Container temperature management is a critical aspect of container climate control. It involves maintaining an optimal temperature inside the container to protect the goods from extreme heat or cold. This is particularly important for temperature-sensitive goods such as food items, pharmaceuticals, and electronics, which can be damaged by extreme temperatures. Temperature management is achieved through the use of insulation materials and temperature control systems, which can regulate the internal temperature of the container based on the external conditions.

Moisture Control in Containers: A Crucial Aspect

Moisture control in containers is a critical aspect of container climate control, directly impacting the integrity and quality of the goods being transported. High humidity levels inside a container can lead to the formation of condensation, which can subsequently cause moisture damage to the goods. This is particularly problematic for goods that are sensitive to moisture, such as electronics, textiles, and certain types of food products.

Signs of Climatic Stress in Containers

| Sign | Cause | Result |

|---|---|---|

| Condensation (Container Rain) | Temperature changes causing moisture to condense | Water damage to goods |

| Rust | High humidity and moisture exposure | Degradation of metal surfaces |

| Mold | Excess moisture inside the container | Spoilage of goods, especially textiles |

The use of desiccants is one of the most effective strategies for moisture control in containers. Shipping container desiccants are substances that absorb excess moisture from the air, helping to maintain a safe and optimal humidity level inside the container. They work by creating a dry environment that inhibits the formation of condensation, thereby protecting the goods from moisture damage. Desiccants come in various forms, including silica gel, calcium chloride, and activated clay, each with its unique absorption properties and benefits.

Ventilation systems also play a crucial role in moisture control. Proper ventilation ensures a continuous flow of air inside the container, preventing the buildup of moisture and maintaining a balanced humidity level. It also helps to dissipate heat and prevent the accumulation of harmful gases that could pose a risk to the goods and the people handling them. Ventilation systems in containers can range from passive vents that allow natural air circulation to more sophisticated active ventilation systems that regulate air flow based on the internal conditions of the container.

In addition to desiccants and ventilation systems, moisture control can also be achieved through the use of moisture-resistant packaging materials and the proper loading and unloading practices. For instance, goods should be properly packed and sealed to prevent exposure to moisture, and containers should be loaded and unloaded in dry conditions to minimize the introduction of moisture.

Recommended Products for Container Climate Control

Desiccants for shipping containers, like the IPD products mentioned, are effective tools for absorbing excess moisture and maintaining an optimal humidity level.

Here are some products that can help manage the cryptoclimate in your shipping containers:

- IPD 1000g Container Desiccant for High-Quality Shipping – This desiccant is designed to absorb moisture in shipping containers, ensuring the safe transportation of goods. It comes in a pack of 15 pieces per box.

- IPD 500g Container Desiccant for High-Quality Shipping – This desiccant offers a balance between the 1000g and 250g options, providing effective moisture absorption for a wide range of goods. It comes in a pack of 30 pieces per box.

- IPD 250g Container Desiccant for High-Quality Shipping – This desiccant is perfect for smaller containers or for goods that are particularly sensitive to moisture. It comes in a pack of 60 pieces per box.

Protecting Your Cargo: A Comprehensive Approach

Ensuring cargo safety from climatic stresses is a top priority in container handling, requiring a comprehensive approach that includes proper packing, climate control, and choosing the right shipping route.

Tools for Monitoring Climatic Stresses in Containers

| Tool | Function | Benefit |

|---|---|---|

| Humidity Sensors | Monitors real-time humidity levels in the container | Allows for immediate action to prevent moisture damage |

| Temperature Sensors | Tracks temperature fluctuations | Helps maintain stable conditions |

| Desiccant Packs | Absorbs moisture to control humidity levels | Prevents container rain and mold |

Tools for Monitoring Climatic Stresses in Containers

| Tool | Function | Benefit |

|---|---|---|

| Humidity Sensors | Monitors real-time humidity levels in the container | Allows for immediate action to prevent moisture damage |

| Temperature Sensors | Tracks temperature fluctuations | Helps maintain stable conditions |

| Desiccant Packs | Absorbs moisture to control humidity levels | Prevents container rain and mold |

Protecting your cargo from climatic stresses involves more than just controlling the container’s climate. It also involves proper packing, using the right container type, and choosing the right shipping route. By taking a comprehensive approach, you can ensure the safe and efficient transportation of your goods.

Container weatherproofing measures, such as using weather-resistant materials and coatings, can also help protect the container and its contents from climatic stresses.

The Future of Container Handling: Adapting to Climate Variations

As climate change continues to affect weather patterns around the world, the shipping and logistics industry must adapt. This includes developing new technologies and strategies to manage climatic stresses and ensure the safe transportation of goods.

Handling climate variations in shipping involves adapting to changing weather patterns and implementing effective climate control measures.

Navigating the Weather: A Final Word on Container Climatic Stresses

In conclusion, managing climatic stresses in container handling is a critical aspect of ensuring the safe and efficient transportation of goods. By understanding the impact of weather conditions on containers and implementing effective climate control measures, logistics professionals can mitigate the risks and protect their cargo.

Managing weather conditions in container shipping involves monitoring and controlling the container’s climate, as well as choosing the right shipping route and container type.

Frequently Asked Questions

What are climatic stresses in container handling?

Climatic stresses refer to the various weather conditions and environmental factors that can affect the condition of shipping containers and the goods within them. These include temperature fluctuations, humidity levels, and ventilation issues.

How can I control the climate inside a shipping container?

Effective container climate control involves maintaining an optimal temperature and humidity level inside the container and ensuring proper ventilation. This can be achieved through the use of temperature and humidity sensors, ventilation systems, and desiccants.

What is the importance of moisture control in containers?

High humidity levels inside a container can lead to condensation, which can damage the goods. Moisture control, achieved through the use of desiccants and ventilation systems, is therefore crucial in preventing moisture damage.

What are the main factors leading to condensation inside a shipping container?

The main factors leading to condensation inside a shipping container are sources of moisture inside the unit, a difference between the temperature of the atmosphere within the unit and the surface temperature of either the cargo or the inner surfaces of the unit itself, and changes in the temperature of the outer surface of the unit.

How does warming the air in a container affect its humidity?

Warming the air in a container causes it to absorb moisture from packagings or any other source. This can increase the humidity level inside the container, which can lead to condensation if the air is cooled below its dew point.

What happens when the outside of a container is cooled after high humidity has been established inside it?

If the outside of a container is cooled after high humidity has been established inside it, the temperature of the unit surface may fall below the dew point of the air inside it. This can cause moisture to form on the inner surfaces of the unit, which may then drop onto the cargo.

Can condensation occur immediately after a container is opened?

Condensation can occur immediately after a container is opened if the air inside the unit is humid and the outside air is relatively cool. This can produce a fog and even precipitation, but because this phenomenon usually occurs only once, it seldom results in serious damage.

How can the risk of damage from condensation be minimized?

The risk of damage from condensation can be minimized by keeping the moisture content of the packaging and securing materials low. This can be achieved through the use of desiccants and proper ventilation.

Read More

For more information on related topics, check out the following articles:

- Container Cryptoclimate and Its Impact on Goods

- Shipping Highly Perishable Goods: A Comprehensive Guide

- The Ultimate 2023 Resource for Shipping Container Desiccants: A Comprehensive Collection of Guides and Tips

- InterDry Power Desiccant

This article provides an in-depth look at the climatic stresses that can affect container handling and offers practical advice on how to manage these challenges. Whether you’re a logistics professional, a shipping company, or a business that relies on shipping for its operations, this article is a must-read.

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้