Comparing CO₂ Adsorption and N₂ Adsorption on Activated Carbon, Alumina, and Zeolites: Insights for Carbon Capture and Gas Purification

| Key Topic | Summary |

|---|---|

| CO₂ Adsorption | The process of capturing CO₂ from the air using different adsorbents like activated carbon, activated alumina, and zeolites. |

| Adsorbents Compared | Zeolite 3A, Zeolite 13X, Activated Alumina, and Activated Carbon were analyzed for their effectiveness in CO₂ and N₂ adsorption. |

| Best Adsorbent | Zeolite 3A was found to be the most effective for selective CO₂ adsorption, while activated alumina also performed well. |

| Impact of Temperature & Steam | Higher temperatures and steam presence can significantly affect adsorption efficiency, highlighting the need for optimal control. |

| Future Directions | Multi-step systems and further refining adsorption processes are essential for improving carbon capture technologies. |

Table Of Contents

The potential advances in adsorption technologies are exciting. With better adsorption materials and smarter system designs, we can achieve cleaner industrial practices.”

Introduction: The Importance of Gas Purification in the Modern World

Imagine if capturing CO₂ from the air could be as simple as a sponge soaking up water—this is what adsorption technology aims to achieve. With carbon capture technology, we’re taking a giant leap toward reducing greenhouse gas emissions and mitigating the effects of climate change. The significance of CO₂ adsorption lies in its ability to help industries efficiently capture carbon dioxide and nitrogen gases, ultimately ensuring cleaner air and a healthier planet.

We live in an era where addressing climate change is no longer optional; it’s a necessity. Industries across the globe are exploring effective methods of removing CO₂ from flue gases before they reach the atmosphere. With the advancements in adsorption technologies, capturing both CO₂ and N₂ has become more efficient. Today, I’m excited to share how activated alumina and other adsorbents are contributing to carbon capture and gas purification—bringing us closer to a more sustainable future.

CO₂ Adsorption

| Adsorbent | Adsorption Capacity (mg/g) | Selectivity | Temperature Effect | Steam Effect |

| Activated Carbon | Moderate | Low | Decreases | High Impact |

| Activated Alumina | High | Moderate | Decreases | Moderate Impact |

| Zeolite 3A | Very High | High | Decreases | Low Impact |

| Zeolite 13X | High | Moderate | Decreases | Moderate Impact |

What is Adsorption and Why Does it Matter?

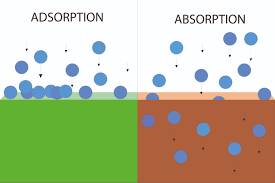

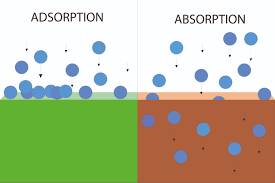

Adsorption might sound complicated, but at its core, it’s just about trapping molecules—kind of like how Velcro catches lint. When we talk about CO₂ adsorption, we’re referring to the process where CO₂ molecules stick to the surface of an adsorbent material. This process helps separate harmful gases from emission streams, allowing for a cleaner output.

CO₂ and N₂ adsorption have their unique challenges, given the different properties of these gases. CO₂ is particularly important to capture because of its role in climate change. Nitrogen, on the other hand, is abundant in the atmosphere, and removing water vapor from N₂ streams can help refine it for industrial uses. Understanding these differences and why certain adsorbents work better for specific gases is crucial for making adsorption processes as effective as possible.

The Role of Adsorbents: Activated Carbon, Alumina, and Zeolites

Choosing the right adsorbent is like picking the perfect tool from a toolbox—each material has its strengths and weaknesses. In CO₂ adsorption, we have a few heavy hitters: activated carbon, activated alumina, zeolite 3A, and zeolite 13X. Each of these materials has unique properties that make them suitable for different roles in gas purification.

Activated carbon adsorption, for instance, is great for many organic compounds but may not always be the best choice for CO₂ removal due to its relatively lower selectivity compared to zeolites. On the other hand, activated alumina provides an effective surface area with a good balance of adsorption capabilities. Zeolite 3A and 13X are often used in competitive settings, as they provide excellent selectivity for CO₂ adsorption, especially when mixed gases are involved. Picking the right adsorbent depends on the specific conditions and gases you are dealing with, making this a critical part of designing effective carbon capture systems.

One of the biggest challenges I faced was balancing the properties of each adsorbent—finding the right compromise between adsorption capacity and selectivity. For instance, activated carbon was effective but struggled with CO₂ selectivity compared to zeolites. To address this, I experimented with modifying process parameters like flow rate and temperature to enhance adsorption efficiency, particularly when dealing with mixed gases. I found that activated alumina offered an excellent middle ground with versatility, while the precision of zeolite 3A was invaluable in achieving optimal results, especially when dealing with high moisture content.

Adsorbent Properties

| Adsorbent | Surface Area (m²/g) | Selectivity | Common Application |

| Activated Carbon | 800 – 1200 | Moderate | Organic compounds |

| Activated Alumina | 200 – 400 | Moderate | Moisture removal, CO₂ adsorption |

| Zeolite 3A | 500 – 700 | High | CO₂ and moisture separation |

| Zeolite 13X | 700 – 900 | Moderate | Bulk gas treatment |

Comparing Adsorbents for CO₂ and N₂: Who Performs Best?

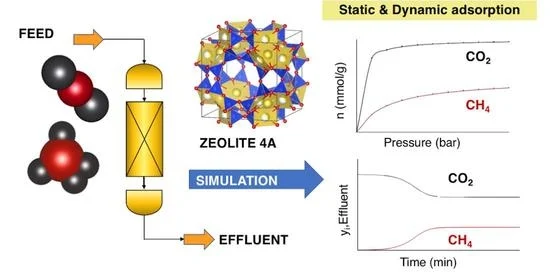

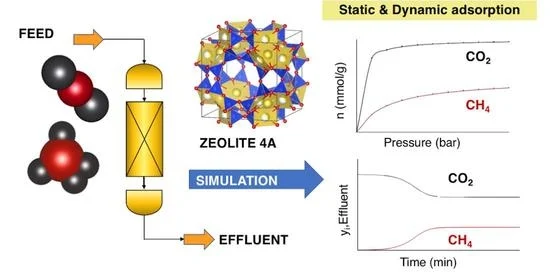

Just like athletes have different specialties, activated carbon, alumina, and zeolites excel at different parts of the adsorption game. When comparing CO₂/H₂O and N₂/H₂O adsorption, we need to look at various factors, including temperature, flow rate, and steam mole fraction. The dynamic adsorption experiments revealed how each adsorbent performed under these changing conditions, showcasing the differences in adsorption capacities.

The adsorption breakthrough curves are a crucial part of understanding how effectively each material works. For example, zeolite 3A showed the highest selectivity, providing the best results for CO₂ adsorption, especially in the presence of water vapor. Activated alumina also held its own, performing well for both CO₂ and N₂ adsorption. Activated carbon, while still useful, tended to lag behind when it came to efficiency, particularly with CO₂, largely due to its physical characteristics.

Factors Affecting Adsorption Performance

- Temperature

- Steam Mole Fraction

- Adsorbent Pore Size

- Flow Rate

- Adsorption Selectivity

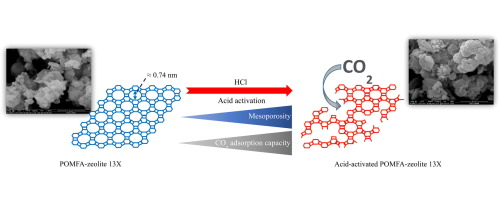

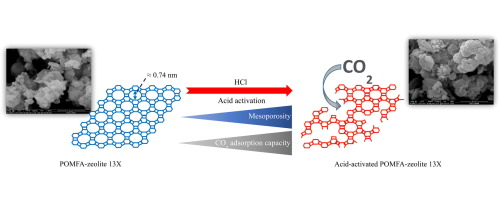

Zeolite 3A vs. Zeolite 13X: The Adsorption Heavyweights

When it comes to CO₂ adsorption, zeolite 3A and zeolite 13X are like the heavyweight champions—each has unique strengths, but only one can be crowned the most efficient. Zeolite 3A stands out because of its smaller pore size, which makes it more selective in capturing CO₂ while effectively excluding other molecules. This makes it an excellent candidate for applications where selective adsorption of gases is crucial.

Zeolite 13X, however, isn’t far behind. Its larger pore structure makes it effective in a wider range of adsorption tasks, but it lacks the extreme selectivity of zeolite 3A. If the goal is to purify gases such as CO₂ and N₂ from mixed streams, zeolite 3A provides an advantage in precision. Zeolite 13X, however, finds use in cases where larger volumes of gas need to be treated. Comparing these two gives us insights into optimizing adsorption systems for carbon capture technology.

Zeolite Comparison

| Property | Zeolite 3A | Zeolite 13X |

| Pore Size | Smaller | Larger |

| Adsorption Selectivity | High | Moderate |

| Typical Use | CO₂ Separation | Bulk Gas Treatment |

In designing carbon capture systems, the differences between zeolite 3A and 13X play a crucial role in deciding which adsorbent to use for a particular application. Zeolite 3A’s smaller pore size makes it superior in applications requiring high selectivity for CO₂, particularly where other gases or impurities are present. For instance, in a project involving the purification of CO₂ from a mixed flue gas stream, zeolite 3A outperformed 13X due to its ability to selectively adsorb CO₂ and exclude water molecules more effectively. However, in scenarios involving bulk gas treatment with fewer impurities, zeolite 13X was more cost-effective due to its higher capacity. The key is understanding the gas composition and operational requirements to select the best adsorbent for the job.

Effect of Steam and Temperature on Adsorption Efficiency

Water vapor may seem harmless, but it can seriously throw a wrench into the works when it comes to effective adsorption. The presence of steam in the gas mixture can significantly affect the adsorption efficiency, particularly in CO₂ and N₂ streams. The steam mole fraction directly impacts breakthrough times and adsorption saturation. As steam increases, it tends to compete for adsorption sites, lowering the overall efficiency of CO₂ adsorption.

Temperature also plays a critical role in this dynamic. Higher temperatures typically reduce the adsorption capacity, especially for CO₂. Imagine trying to stack Lego blocks on a shaky table—higher temperatures make the adsorption process less stable and effective. The balance between steam presence and temperature needs careful management to ensure maximum efficiency in capturing CO₂ and N₂, especially when using activated alumina or zeolites.

The presence of steam in gas streams can significantly reduce adsorption efficiency due to its competition for active adsorption sites. To mitigate these effects, I have often employed multi-stage adsorption processes, where activated alumina is used first to deal with moisture before targeting CO₂ or N₂. By carefully managing the steam mole fraction and maintaining moderate operational temperatures, I’ve seen notable improvements in both CO₂ and N₂ adsorption efficiency, particularly when using zeolites like 3A. This approach not only enhances the effectiveness of the adsorption process but also ensures better control over breakthrough times.

Understanding Adsorption Kinetics and Thermal Effects

Adsorption is more than just sticking molecules to a surface—it’s a complex dance influenced by heat and time. The adsorption kinetics of CO₂ and N₂ give us valuable insights into how fast and effectively these gases can be captured. The thermal effects, such as the thermal wave peaks observed during adsorption, are also critical in understanding how adsorbents behave under different conditions.

“Adsorption is more than just sticking molecules to a surface—it’s a complex dance influenced by heat and time.”

The experiments conducted showed that the thermal wave peak for N₂/H₂O is delayed compared to CO₂/H₂O, indicating a slower adsorption rate for nitrogen. These insights help optimize carbon capture systems, making sure that the heat generated during adsorption is managed effectively, and adsorption beds are designed to maximize performance. Activated alumina, with its moderate thermal conductivity, offers a good balance for controlling the thermal effects during adsorption.

Thermal Effects in Adsorption

| Gas Mixture | Thermal Wave Peak (Minutes) | Peak Temperature (°C) |

| CO₂/H₂O | 3.5 – 7.0 | 40 – 55 |

| N₂/H₂O | 4.2 – 8.3 | 38 – 50 |

Implications for Carbon Capture Technology and Gas Purification

So, why does all of this matter? Well, making adsorption more efficient is key to making carbon capture technology feasible on a larger scale. The insights gained from comparing different adsorbents help engineers design systems that are more effective at capturing CO₂, which is crucial for reducing industrial emissions and moving towards a carbon-neutral future. For more information about the findings discussed here, you can refer to the original study on ScienceDirect.

By using materials like activated alumina and zeolites, industries can improve the sustainability and scalability of their gas purification systems. Activated alumina provides versatility, while zeolites bring the precision needed for targeted gas removal. Together, these materials hold the promise of more efficient CO₂ removal from flue gas, reducing the environmental impact of various industrial processes.

Benefits of Activated Alumina in Gas Purification

- Versatility in Gas Streams

- High Moisture Adsorption

- Cost-Effective Solution

- Ease of Regeneration

- Suitable for CO₂ and N₂ Purification

Molecular Sieves for Carbon Capture: Reducing Emissions Effectively

Discover how molecular sieves play a critical role in carbon capture and environmental applications, helping industries reduce CO₂ emissions and achieve sustainability goals. From biogas purification to advanced emission control, molecular sieves are integral to creating eco-friendly solutions across energy, automotive, and industrial sectors. Learn more about their impact and applications in our in-depth guide here.

Future of Adsorption-Based Gas Purification

As we look to the future, there’s still plenty of room to innovate and refine adsorption techniques for better results. One promising direction is the development of multi-step adsorption systems. By designing systems that first remove water vapor and then proceed to target specific gases like CO₂ and N₂, we can significantly enhance the efficiency of gas purification.

The potential advances in adsorption technologies are exciting. From exploring new adsorbent materials to optimizing existing processes, the path forward is filled with opportunities for innovation. With better adsorption materials and smarter system designs, we can make significant strides toward achieving cleaner industrial practices and more efficient carbon capture.

Frequently Asked Questions

What is CO₂ adsorption?

CO₂ adsorption is the process of capturing carbon dioxide molecules from a gas stream by allowing them to adhere to the surface of an adsorbent material like activated carbon, alumina, or zeolite.

How does N₂ adsorption differ from CO₂ adsorption?

N₂ adsorption differs from CO₂ adsorption primarily in terms of selectivity and adsorption capacity. CO₂ is more polar and has higher adsorption potential, while N₂ adsorption is often less selective and challenging due to nitrogen’s inert nature.

Why is activated alumina used for gas purification?

Activated alumina is used for gas purification because it has a high surface area and can effectively adsorb moisture and gases like CO₂. Its versatility makes it suitable for multiple gas streams.

How does activated carbon compare to zeolites for CO₂ adsorption?

Activated carbon has a moderate adsorption capacity for CO₂ but lacks the selectivity of zeolites like 3A and 13X, making it less effective for applications where high purity CO₂ is required.

What are adsorption breakthrough curves?

Adsorption breakthrough curves represent the point at which an adsorbent becomes saturated with a gas and the gas starts breaking through into the output stream. They are crucial for evaluating adsorption efficiency.

How do temperature changes impact CO₂ adsorption?

Temperature changes can significantly impact CO₂ adsorption; generally, higher temperatures reduce the adsorption capacity, making the process less efficient.

Which is better: Zeolite 3A or Zeolite 13X?

Zeolite 3A is better for selective CO₂ adsorption due to its smaller pore size, whereas Zeolite 13X is more effective for bulk gas treatment where higher capacities are needed.

What role does steam play in the adsorption process?

Steam competes with gases like CO₂ for adsorption sites, reducing the overall efficiency. High steam presence can decrease breakthrough time and adsorption capacity.

What is the significance of adsorption kinetics?

Adsorption kinetics help determine how quickly a gas molecule can be adsorbed by an adsorbent, providing insight into the efficiency and rate of the adsorption process.

Can activated alumina remove both CO₂ and N₂?

Yes, activated alumina can adsorb both CO₂ and N₂, although it is more effective for CO₂ due to its polar nature and higher affinity for the alumina surface.

What are dynamic adsorption experiments?

Dynamic adsorption experiments involve passing gas mixtures through an adsorbent bed under controlled conditions to study adsorption capacity, kinetics, and breakthrough behavior.

How does pore size affect adsorption?

Pore size affects adsorption by determining which gas molecules can enter and be trapped. Smaller pores are more selective, making materials like Zeolite 3A highly effective for CO₂ adsorption.

Why is selective adsorption of gases important?

Selective adsorption is crucial for separating specific gases from mixed streams, ensuring that only the target gas, like CO₂, is captured while others are left untreated or treated separately.

How does activated alumina compare to zeolites for N₂ adsorption?

Activated alumina has moderate capacity for N₂ adsorption but is less selective compared to zeolites like 3A and 13X. Zeolites are better for applications requiring high purity and selective separation, while activated alumina offers versatility in mixed gas environments.

What is the importance of adsorption breakthrough curves?

Adsorption breakthrough curves are important because they provide information about when an adsorbent becomes saturated and can no longer effectively capture a gas. This helps in determining the efficiency and lifespan of the adsorbent during dynamic adsorption experiments.

Can zeolites be used in carbon capture technology?

Yes, zeolites, especially 3A and 13X, are highly effective in carbon capture technology due to their high selectivity for CO₂. Their pore structure allows for efficient adsorption of CO₂, making them suitable for capturing carbon dioxide from flue gases.

How does activated carbon adsorption compare to activated alumina?

Activated carbon adsorption is effective for a variety of organic compounds, but it has lower selectivity for CO₂ compared to activated alumina. Activated alumina, with its higher adsorption capacity for moisture and gases like CO₂, is often preferred in scenarios requiring versatility and efficiency.

What is the role of adsorption kinetics in gas purification?

Adsorption kinetics play a crucial role in determining how fast a gas can be captured by an adsorbent. Faster kinetics mean quicker adsorption, which is important for optimizing the design and performance of gas purification systems, especially in carbon capture applications.

Why is zeolite 3A considered more selective than zeolite 13X?

Zeolite 3A is considered more selective because of its smaller pore size, which allows it to effectively trap CO₂ molecules while excluding other gases. This makes it ideal for applications requiring precise separation, whereas zeolite 13X is better for bulk treatment.

How does steam presence affect the adsorption efficiency of activated carbon?

The presence of steam significantly reduces the adsorption efficiency of activated carbon because water vapor competes with CO₂ for adsorption sites. This competition makes it harder for activated carbon to effectively capture CO₂ in humid environments, often requiring additional steps for moisture removal.

Conclusion: Finding the Right Adsorbent for the Job

Whether it’s CO₂ or N₂, finding the right adsorbent is crucial to capturing emissions efficiently and effectively. Activated alumina, activated carbon, and zeolites each bring something different to the table. Choosing the right one depends on understanding the specific needs of the process, the gas composition, and the operational conditions involved.

As we continue to develop better carbon capture technologies, the right combination of adsorbents can make all the difference. These technologies are key to mitigating climate change, and it’s essential to keep pushing the boundaries of what’s possible in gas purification. Let’s embrace these advancements as a way to ensure a cleaner, more sustainable future for all.

Call to Action

Have you ever wondered how industrial emissions could be captured more efficiently? Activated Alumina plays a crucial role in many adsorption systems today. Learn more about the product on our Activated Alumina page. You can also explore other options like Molecular Sieve 3A for specialized applications: Molecular Sieve 3A.

To fully understand the versatility of activated alumina, we invite you to explore other applications of Activated Alumina in diverse industries. From gas purification and moisture control to catalytic processes, activated alumina plays a critical role in enhancing efficiency and ensuring quality across a range of industrial uses.

For a deeper dive into how these adsorbents can benefit your processes, check out our detailed guide: A Complete Guide to Activated Alumina and Choosing the Right Desiccant for Compressed Air Systems: A Comparison of Activated Alumina, Silica Gel, and Molecular Sieves and The Benefits of Activated Carbon for Air Purification and The Science Behind PSA: How Pressure Swing Adsorption Powers Our Industries or our Comprehensive Guide to Activated Carbon 2024

Proper maintenance of adsorption media is essential to keep nitrogen generators performing at their best. Learn how molecular sieves and activated carbon filters work together to maintain high nitrogen purity and system reliability in our in-depth guide on Media Replacement and Servicing for PSA Nitrogen Systems. This article explains the complete process—from identifying performance decline to professional desiccant replacement—helping plant engineers and maintenance teams extend equipment life and reduce downtime.

Disclaimer

The information provided in this blog post is intended for informational purposes only. For specific advice on adsorption technologies or material selection, please consult a qualified professional or reach out to our team.

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้