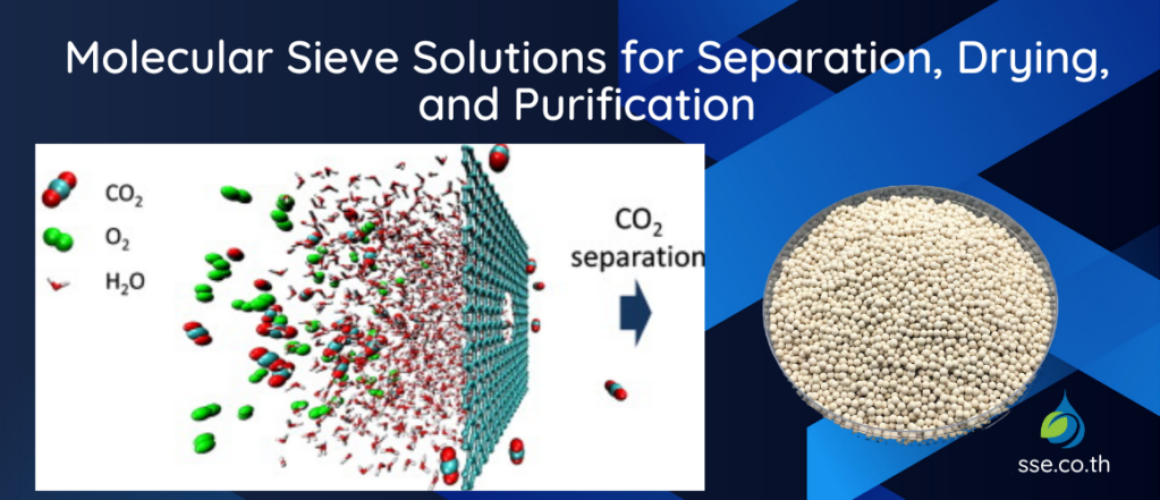

Optimizing Gas Purity: Molecular Sieve Solutions for Separation, Drying, and Purification

| Topic | Description |

|---|---|

| Gas Separation | Isolates specific gases, such as oxygen and nitrogen, from mixtures for high-purity applications. |

| Gas Drying | Removes moisture from gas streams, preventing corrosion and enhancing gas stability. |

| Gas Purification | Removes multiple impurities, including VOCs and sulfur compounds, improving gas quality and equipment lifespan. |

| Choosing the Right Sieve | Selecting based on gas type, pore size, and specific needs optimizes performance and cost-effectiveness. |

| Applications | Molecular sieves support industries from petrochemical processing to healthcare and environmental protection. |

Table Of Contents

Introduction

When we think about purity, it’s often in terms of filtered water or organic food. But gas purity is essential across various industries, where high-quality gases are fundamental to safety, efficiency, and regulatory compliance. Whether it’s providing clean oxygen for medical purposes, purifying natural gas in petrochemical facilities, or drying compressed air systems, achieving gas purity is essential—and molecular sieves are central to making this happen.

| Industry | Importance of Gas Purity | Key Applications |

|---|---|---|

| Medical | Patient safety and oxygen concentration | Oxygen concentrators |

| Petrochemical | Product quality, equipment protection | Fuel purification, sulfur removal |

| Food and Beverage | Prolonged shelf life, product freshness | Nitrogen flushing for packaging |

| Pharmaceuticals | Stability of compounds, product quality | Drying and purifying active ingredients |

| Environmental Systems | Reduction of hazardous emissions | VOC and sulfur compound removal |

From my experience, molecular sieves are incredibly versatile in gas separation, gas drying, and gas purification applications, providing efficient and cost-effective ways to achieve desired purity levels. This article will walk you through these applications, explaining how molecular sieves enhance gas purity and sharing links to more in-depth resources.

Benefits of Achieving Gas Purity with Molecular Sieves in Industry

- Protects critical equipment and infrastructure from corrosion

- Enhances product quality by removing unwanted impurities

- Ensures regulatory compliance for emission standards

- Lowers operational costs by reducing maintenance and downtime

- Supports environmental sustainability by reducing hazardous emissions

For more foundational information, see A Comprehensive Guide to Molecular Sieves.

What Are Molecular Sieves and Why Are They Essential?

| Molecular Sieve Type | Pore Size | Primary Applications | Key Impurities Targeted |

|---|---|---|---|

| 3A | 3 Å | Moisture removal, gas drying | Water vapor |

| 4A | 4 Å | CO₂ removal, hydrocarbon drying | CO₂, moisture |

| 5A | 5 Å | Gas separation, particularly O₂-N₂ | Nitrogen |

| 13X | 10 Å | VOC adsorption, sulfur compound adsorption | VOCs, sulfur compounds, ammonia |

| MSOX | Variable | High-purity oxygen generation | Nitrogen, CO₂ (in PSA systems) |

Molecular sieves are highly specialized filtering materials, often made of zeolites, with uniform pores that allow them to selectively adsorb certain molecules while letting others pass through. Imagine them as tiny, molecular-level “bouncers” that allow only specific molecules to enter. Their precision makes molecular sieves indispensable in applications where gas purity matters, from industrial gas drying to petrochemical gas purification.

Industries that Rely on High Gas Purity Standards

- Petrochemical: For gas processing and purification.

- Medical: Producing high-purity oxygen and nitrogen.

- Food and Beverage: Preserving products with controlled atmospheres.

- Pharmaceuticals: Ensuring stability in drug manufacturing.

- Environmental Services: Controlling emissions and VOCs.

They’re reusable, environmentally friendly, and effective for applications ranging from drying gases to removing volatile organic compounds (VOCs) from industrial streams. If you’re curious about how molecular sieves work, visit How Molecular Sieves Work for a deeper dive.

Gas Separation: Ensuring High-Purity Gases

| Process | Molecular Sieve Type | Target Gas | Industry |

|---|---|---|---|

| Oxygen-Nitrogen Separation | 5A, MSOX | Pure oxygen | Medical, industrial gas generation |

| CO₂ Removal | 4A, 13X | Purified natural gas | Petrochemical |

| Hydrogen Purification | 5A | Purified hydrogen | Fuel cells, refining |

| Nitrogen Production | 5A | High-purity nitrogen | Metal fabrication, food processing |

Purpose of Gas Separation

Gas separation involves isolating specific gases from mixtures, creating streams of high-purity gas. This is particularly valuable in medical oxygen concentrators, which separate oxygen from nitrogen to deliver concentrated oxygen for patient use. Molecular sieves also enable industrial gas generation by separating gases to specific purity levels, critical in chemical manufacturing and metal processing.

How Molecular Sieves Support Gas Separation

Molecular sieves, particularly types like 5A and MSOX, are excellent at selectively adsorbing certain gases based on molecular size and polarity. For instance, oxygen-nitrogen separation in oxygen concentrators relies on molecular sieves to capture nitrogen, allowing pure oxygen to flow through. To learn more about these specific applications, check out Choosing Zeolite Molecular Sieve for Oxygen Generators.

Industrial Applications

Applications of gas separation using molecular sieves are widespread:

- Medical Industry: Producing pure oxygen for respiratory support.

- Food Packaging: Removing oxygen to prolong shelf life.

- Metal Fabrication: Pure oxygen aids in high-temperature metal cutting and welding.

Molecular sieves provide a reliable, energy-efficient method for achieving high-purity gases, making them a go-to solution in industries requiring exacting standards. To explore more, visit our dedicated article on Gas Separation with Molecular Sieve.

Gas Drying: The Role of Molecular Sieves in Moisture Control

Purpose of Gas Drying

Gas drying is a critical step in ensuring gas purity, as moisture can lead to corrosion, freezing, and unwanted chemical reactions. Removing water vapor from gases like natural gas or compressed air prevents these issues and is essential for reliable, long-lasting operations.

How Molecular Sieves Remove Moisture

Molecular sieves like 3A are specially designed to adsorb water molecules, removing moisture without affecting other gas components. By acting as a microscopic “sponge,” these sieves achieve ultra-low moisture levels essential for many industrial applications. This makes them invaluable in industrial gas drying where moisture removal is critical.

Real-World Applications

Gas drying with molecular sieves has multiple uses:

- Natural Gas Processing: Removes moisture to prevent pipe corrosion.

- Compressed Air Systems: Prevents rust and ensures smooth operation.

- Pharmaceuticals: Protects sensitive compounds from degradation due to moisture.

For further insights on the benefits of molecular sieves in drying applications, see The Benefits of Using Molecular Sieves in Gas Drying Applications.

Gas Purification: Comprehensive Impurity Removal for High Gas Purity

| Impurity Type | Source | Targeted Molecular Sieve | Impact if Not Removed |

|---|---|---|---|

| Volatile Organic Compounds (VOCs) | Industrial emissions | 13X | Air pollution, odor |

| Sulfur Compounds (e.g., H₂S) | Natural gas, fuel production | 13X | Corrosion, reduced fuel quality |

| Ammonia | Wastewater, petrochemical streams | 13X | Corrosion, equipment degradation |

| Moisture | Compressed air, natural gas | 3A, 4A | Corrosion, blockages in pipelines |

Purpose of Gas Purification

Gas purification goes beyond moisture control; it’s about removing a variety of impurities, from sulfur compounds to VOCs and ammonia. These contaminants can degrade product quality, corrode equipment, and even pose safety hazards, making purification a priority in industries such as petrochemicals and pharmaceuticals.

How Molecular Sieves Enhance Gas Purity

With their larger pores, molecular sieves like 13X can adsorb a range of impurities, including VOCs and sulfur compounds. This broad-spectrum adsorption capability makes them ideal for applications that require comprehensive gas purification. For an example of how CO₂ and N₂ can be selectively adsorbed to improve gas purity, read our post on CO₂ Adsorption and N₂ Adsorption.

Industrial Applications

Gas purification with molecular sieves is crucial in:

- Petrochemical Processing: Removes sulfur compounds that cause corrosion and reduce fuel quality.

- Environmental Systems: Captures VOCs and other pollutants, enhancing air quality.

- Food Processing: Ensures gases used in food preservation are free from contaminants.

To learn more about the power of molecular sieves in removing VOCs, ammonia, and sulfur compounds, explore Adsorption Solutions with Molecular Sieves: Targeting VOCs, Ammonia, and Sulfur Compounds.

Choosing the Right Molecular Sieve for Your Application

Selecting the right molecular sieve is essential to achieving desired gas purity. Here are some considerations:

- Type of Gas or Impurity: Certain molecular sieves are tailored to specific impurities; 3A for moisture, 5A for nitrogen, and 13X for VOCs.

- Operational Conditions: Temperature, pressure, and flow rate affect sieve performance and should match your specific application needs.

- Purity Levels Required: Higher purity may need multi-stage processes or specialized sieve types to achieve effective results.

Key Factors for Choosing the Right Molecular Sieve

- Target Gas or Contaminant: Select based on specific impurities like moisture, VOCs, or sulfur compounds.

- Operational Conditions: Consider temperature, pressure, and flow rate for optimal adsorption.

- Purity Requirements: Higher purity may require a combination of sieve types.

- Regeneration Capability: Choose sieves that allow for easy regeneration for long-term use.

Anecdote

In a project with natural gas purification, switching to a 13X molecular sieve optimized sulfur compound adsorption, enhancing gas purity significantly. Small adjustments in sieve selection can lead to noticeable improvements in efficiency and product quality.

For more guidance on choosing the right molecular sieve for your application, explore our Molecular Sieve Product List.

Real-World Benefits and Industry Insights

Using molecular sieves to optimize gas purity brings several key advantages:

- Enhanced Gas Quality: By capturing moisture and impurities, molecular sieves ensure gases meet industry standards for purity.

- Equipment Longevity: Removing contaminants like sulfur compounds prevents corrosion, extending equipment lifespan.

- Cost Efficiency: Reusable molecular sieves reduce waste and maintenance costs, offering a cost-effective purification method.

- Regulatory Compliance: Many industries are subject to environmental regulations on emissions, and molecular sieves help meet these standards by removing harmful compounds.

Key Benefits of Using Molecular Sieves for Gas Purity

- Enhanced gas purity for high-quality output

- Improved equipment longevity by reducing corrosion

- Cost-effectiveness through sieve reusability

- Regulatory compliance by meeting environmental standards

- Versatility in applications across multiple industries

Industry Trends

As molecular sieve technology evolves, new materials are improving adsorption rates and enhancing specific applications like VOC removal from gas and specialized gas purification methods. With greater adsorption efficiency and reduced regeneration energy requirements, molecular sieves continue to be refined for industrial demands. MSOX molecular sieves, for example, are leading the way in oxygen concentrators, providing improved oxygen generation capabilities. Learn more in our post on The Power of MSOX Molecular Sieves.

For a deeper scientific overview of molecular sieves, check out this resource on Molecular Sieves.

Frequently Asked Questions

What is gas purity, and why is it important?

Gas purity refers to the level of cleanliness in a gas stream, free from unwanted impurities. High gas purity is crucial in various industries to ensure product quality, protect equipment, and comply with safety regulations.

How do molecular sieves contribute to gas purity?

Molecular sieves remove specific impurities from gases by adsorbing unwanted molecules based on size and polarity. This selective adsorption enables them to enhance gas purity in separation, drying, and purification processes.

What types of gases can be purified with molecular sieves?

Molecular sieves are used to purify a range of gases, including oxygen, nitrogen, hydrogen, natural gas, and compressed air, as well as to remove contaminants like sulfur compounds and VOCs.

How does gas separation work with molecular sieves?

In gas separation, molecular sieves selectively adsorb one type of molecule, such as nitrogen, allowing another (like oxygen) to flow through. This creates a purified gas stream, essential in applications like oxygen concentrators.

What’s the difference between gas separation, drying, and purification?

Gas separation isolates specific gases, gas drying removes moisture, and gas purification eliminates multiple impurities. Each process targets different contaminants based on industry requirements.

Which molecular sieve type is best for gas drying?

The 3A molecular sieve is often ideal for gas drying due to its small pore size, which selectively adsorbs water molecules, leaving other gas components unaffected.

Can molecular sieves be regenerated?

Molecular sieves can be regenerated by heating or applying a vacuum to release the adsorbed molecules, making them reusable and cost-effective over time.

What contaminants can molecular sieves remove from gas streams?

Molecular sieves can remove contaminants such as water vapor, sulfur compounds, volatile organic compounds (VOCs), CO₂, and ammonia, ensuring gas purity for various industrial uses.

How does gas drying with molecular sieves prevent corrosion?

By removing moisture from gas streams, molecular sieves prevent water-induced corrosion in pipelines, compressors, and storage tanks, extending equipment lifespan.

How are molecular sieves used in the medical industry?

In medical applications, molecular sieves are used for oxygen-nitrogen separation to produce high-purity oxygen in concentrators, essential for patient care.

What are the benefits of using molecular sieves in petrochemical gas purification?

Molecular sieves in petrochemical purification remove impurities like sulfur compounds and ammonia, which improves fuel quality, protects equipment, and complies with environmental standards.

What is VOC removal, and why is it important?

VOC removal refers to capturing volatile organic compounds from gas streams. This is important to prevent pollution, improve air quality, and meet environmental regulations.

How do I choose the right molecular sieve for gas purification?

Consider factors like the type of gas, specific impurities, operational conditions, and desired purity levels. For example, 13X is effective for VOCs and sulfur compounds, while 3A is best for moisture.

Why are 13X molecular sieves commonly used for sulfur compound adsorption?

13X sieves have larger pores, which makes them suitable for capturing sulfur compounds and other larger molecules, making them ideal for petrochemical and environmental applications.

What’s the role of molecular sieves in nitrogen production?

Molecular sieves, such as 5A, adsorb oxygen, allowing nitrogen to flow through. This process is crucial in producing high-purity nitrogen for applications like food preservation and chemical production.

Are there environmental benefits to using molecular sieves?

Molecular sieves reduce harmful emissions by adsorbing pollutants like VOCs and sulfur compounds, helping industries comply with environmental regulations and reduce their environmental impact.

Can molecular sieves improve the safety of gas systems?

By removing impurities that cause corrosion, freezing, or unwanted reactions, molecular sieves protect equipment and ensure safe operation, especially in high-stakes industries like healthcare and petrochemicals.

How long do molecular sieves last?

Molecular sieves can last several years with proper use and regular regeneration. Their longevity depends on factors such as the level of impurities, operational conditions, and maintenance practices.

What industries rely on molecular sieves for gas purification?

Industries such as petrochemical, medical, environmental, food and beverage, and pharmaceuticals all rely on molecular sieves to achieve high levels of gas purity for safe and efficient operations.

Where can I find a comprehensive range of molecular sieve products?

You can explore our full selection of molecular sieve products in the Molecular Sieve product category to find solutions tailored to your specific gas purity needs.

Conclusion

From gas separation to gas drying and gas purification, molecular sieves are essential tools for achieving and maintaining gas purity. Their versatility, efficiency, and adaptability make them a preferred choice across industries. By selecting the right molecular sieve type and optimizing operational conditions, industries can ensure gas streams meet high standards of purity, protecting both equipment and end products.

To find the ideal molecular sieve solution for your gas purity needs, explore our extensive Molecular Sieve product category. Whether you’re in healthcare, petrochemicals, or food processing, our molecular sieves offer the purity and reliability your processes demand.

ขอบคุณที่ใช้เวลาอ่านบทความของเราเกี่ยวกับการป้องกันความชื้น ทางเราหวังว่าท่านจะได้รับข้อมูลที่มีคุณค่าและเป็นประโยชน์ ทางเรายินดีให้บริการการปรึกษาฟรีเพื่อพูดคุยเกี่ยวกับความต้องการของท่านและให้คำแนะนำเกี่ยวกับวิธีการป้องกันความชื้นที่กำหนดเฉพาะสำหรับคุณ โปรดติดต่อเราที่ 0858124188 เพื่อนัดหมายการปรึกษาหรือเยี่ยมชมร้านค้าของเราเพื่อค้นหาผลิตภัณฑ์ที่ช่วยป้องกันสินค้าของคุณจากความเสียหายจากความชื้น ทางเราหวังว่าจะได้รับข่าวสารจากท่านเร็วๆนี้